Cement produced from electrolytic manganese residues and production method thereof

A technology of electrolytic manganese slag and production method, which is applied in the direction of cement production, etc., can solve the problems that enterprises are difficult to rationally use electrolytic manganese slag, and achieve the effects of stabilizing heavy metals, reducing hydration speed, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

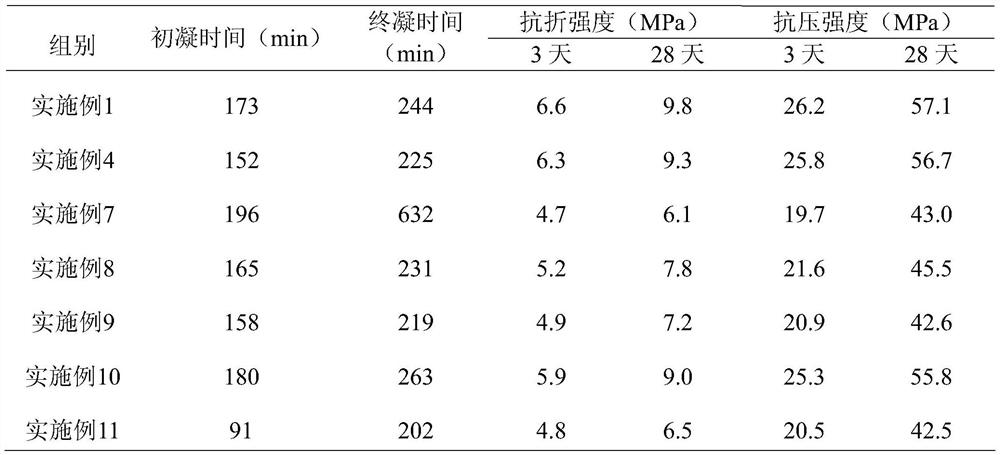

Examples

Embodiment 1

[0025] A cement produced by using electrolytic manganese slag, made of the following raw materials in parts by weight: cement clinker 85, electrolytic manganese slag 12, fly ash 7 and gypsum 1.5; the cement clinker is made of the following raw materials by weight Manufacture: limestone 82, clay 3, river sand 3 and iron ore 2; cement clinker is prepared by the conventional method in this industry, and the calcination temperature is 1450°C.

[0026] In the electrolytic manganese slag, Fe 2 o 3 The content of MnO is 23.5%, and the content of MnO is 16.7%. The electrolytic manganese slag is used after the following treatment: add quicklime after the electrolytic manganese slag is pulverized, wherein the amount of quicklime is 7.3% of the weight of the electrolytic manganese slag, stir and mix to remove ammonia nitrogen, and obtain the pretreated electrolytic manganese slag; Spray the treatment agent into the pretreated electrolytic manganese slag while stirring. The temperature ...

Embodiment 2

[0034] A cement produced by using electrolytic manganese slag, made of the following raw materials in parts by weight: cement clinker 80, electrolytic manganese slag 10, fly ash 5 and gypsum 1; the cement clinker is made of the following raw materials by weight Crafted from: Limestone 80, Clay 2, River Sand 2, and Iron Ore 1.

[0035] In the electrolytic manganese slag, Fe 2 o 3 The content of MnO is 24.0%, and the content of MnO is 17.2%. The electrolytic manganese slag is used after the following treatment: the electrolytic manganese slag is pulverized and then added with quicklime, wherein the amount of quicklime added is 7% of the weight of the electrolytic manganese slag, stirred and mixed to remove ammonia nitrogen, and the pretreated electrolytic manganese slag is obtained; Spray the treatment agent into the pretreated electrolytic manganese slag while stirring. The temperature during the treatment process is controlled at 40°C, the stirring speed is 50r / min, and the ...

Embodiment 3

[0040] A cement produced by utilizing electrolytic manganese slag, made of the following raw materials by weight: cement clinker 90, electrolytic manganese slag 15, fly ash 8 and gypsum 2; the cement clinker is made of the following raw materials by weight Crafted from: Limestone 85, Clay 6, River Sand 5, and Iron Ore 3.

[0041] In the electrolytic manganese slag, Fe 2 o 3 The content of MnO is 22.8%, and the content of MnO is 15.9%. The electrolytic manganese slag is used after the following treatment: add quicklime after crushing the electrolytic manganese slag, wherein the amount of quicklime is 8% of the weight of the electrolytic manganese slag, stir and mix to remove ammonia nitrogen, and obtain the pretreated electrolytic manganese slag; Spray the treatment agent into the pretreated electrolytic manganese slag while stirring. The temperature during the treatment process is controlled at 60°C, the stirring speed is 60r / min, and the treatment time is 30min. 4 、K 2 CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com