AGV carrying and flip robot for medical waste garbage cans

A technology for medical waste and trash cans, which can be applied to instruments, lifting devices, and re-radiation of electromagnetic waves, etc., can solve problems such as hidden safety hazards of trash cans, and achieve the effects of improving utilization, compact overall structure, and reducing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

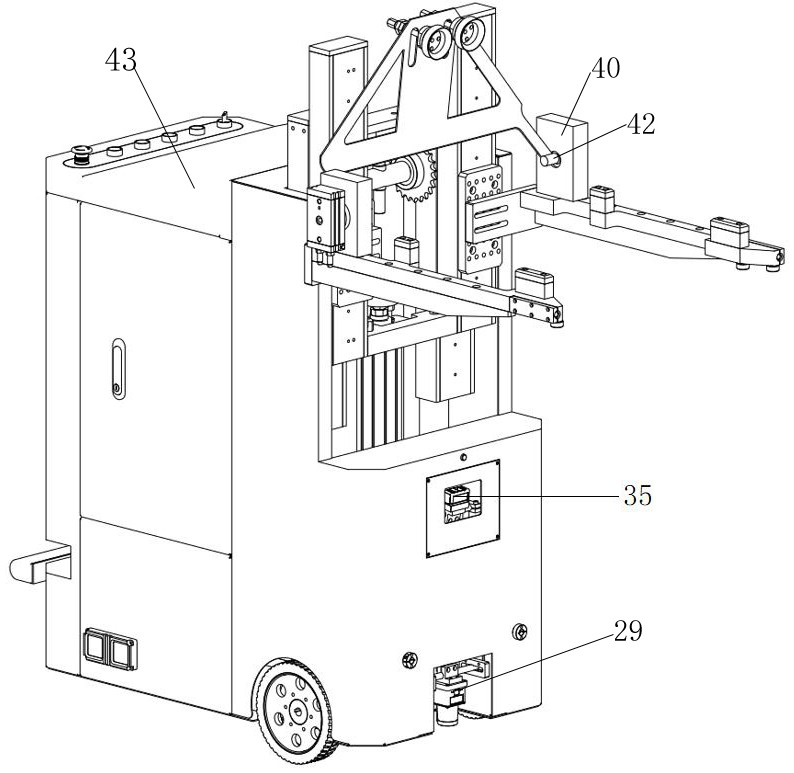

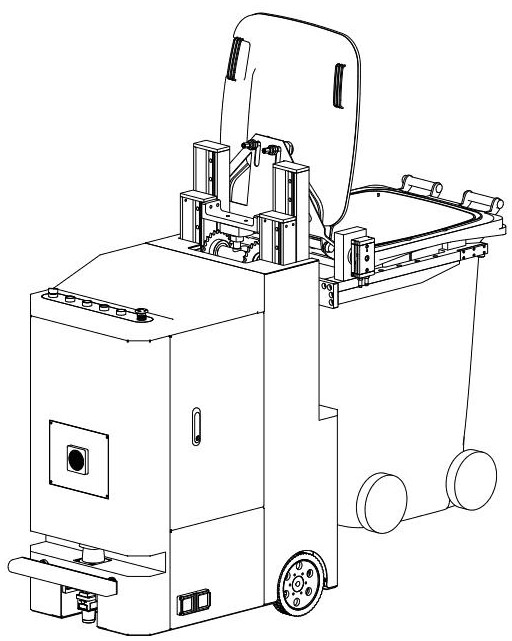

[0035] A medical waste handling clamshell trash AGV robots, such as Figure 1-7 , The mechanism comprising a chassis, the chassis including a chassis frame means 1 is provided with a drive assembly on the chassis frame 1; above the chassis frame of the vehicle body 1 is provided with a means, mechanism includes a body assembly and avoidance navigation components; means disposed on the vehicle body with a lifting mechanism.

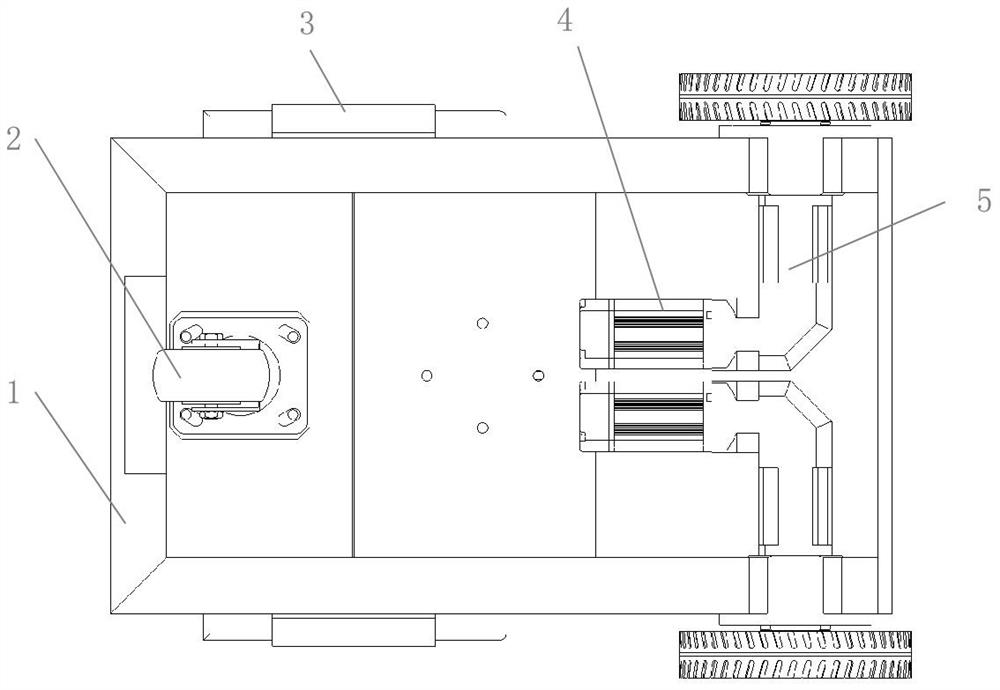

[0036] like figure 1 , image 3 , Figure 4, The drive assembly includes a chassis frame 1 in the front end of the pair of drive wheels 12, the rear end of the chassis frame 1 is connected to a caster 2; each drive wheel 12 are fixedly connected with a drive shaft 11 coaxially therewith, each rotation of the drive shaft 11 is connected to the chassis frame 1; one end of each of a drive shaft 12 connected to drive wheels 11 are connected with a remote gear 5, 5 are at a right angle gear type planetary gear 5, each gear 5 is connected with a servo motor 4, the serv...

Embodiment 2

[0047] Compared with Example 1, the present embodiment is not set flip-lid mechanism. The robot to transport the trash and the trash after a specified down position, the electric cylinder 26 and the cylinder 19 and a slide plate, the slide plate 22 two reset directly without intermediate stop, and leaving the robot to continue to transport the next reset trash.

Embodiment 3

[0049] Compared with Example 1, the present embodiment is not provided on the lifter assembly count weighing embodiment, the bottom end of the support bar 17 directly to the top of the cylinder 26 is fixedly connected electrically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com