Combined plastic pallet

A combined and plastic technology, applied in packaging, transportation, packaging, containers, etc., can solve the problems of pallets not being used normally, shortened service life, and weak load-bearing capacity, so as to save resources, maintain costs, and reduce production costs , Enhance the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, the present invention will be described in detail and completely through specific embodiments in conjunction with the accompanying drawings.

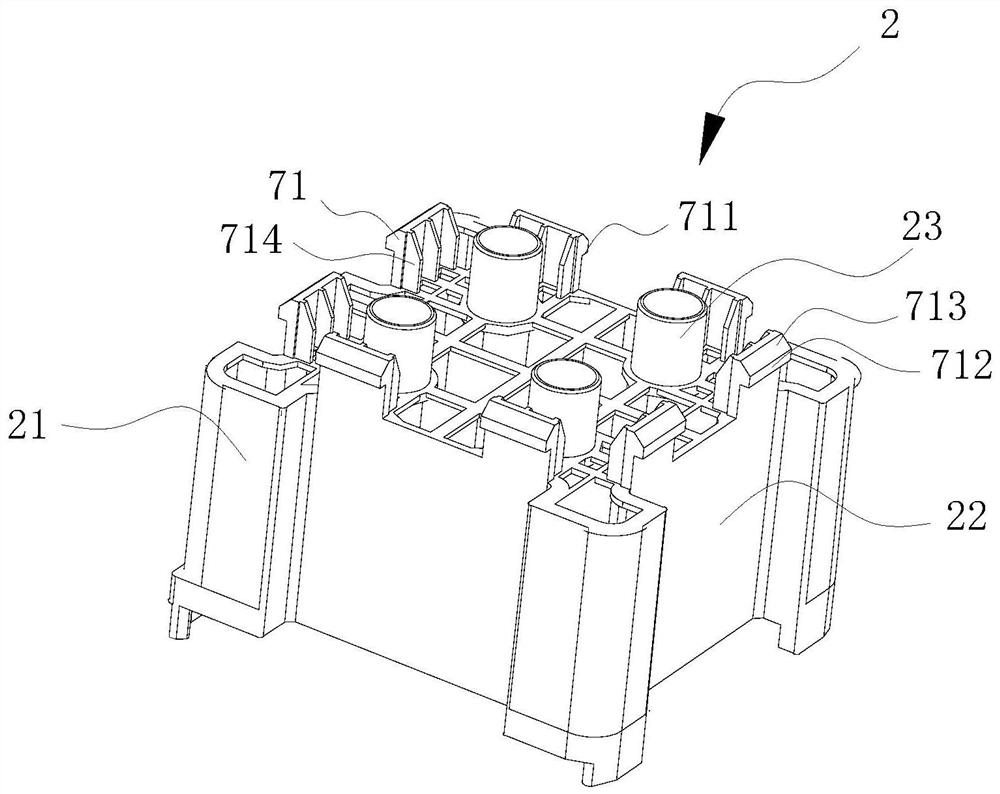

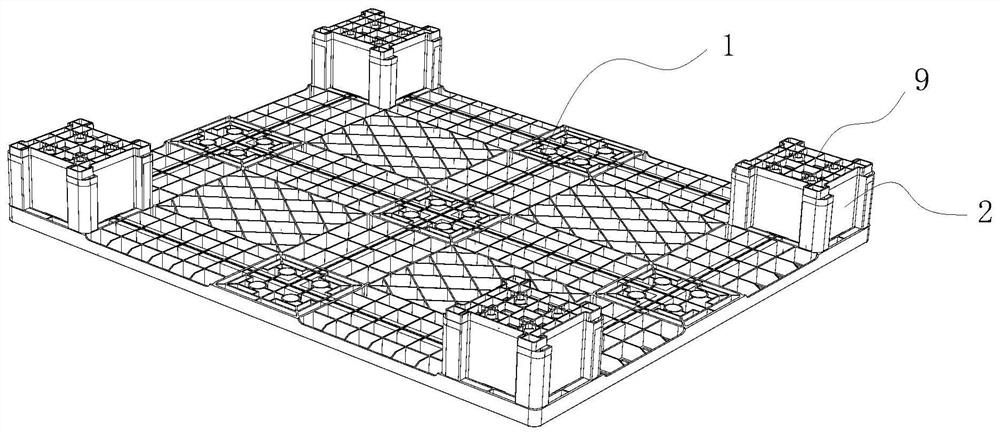

[0030] Please refer to Figure 1-13 As shown, the present invention provides a combined plastic pallet, including a panel 1 and a number of supporting feet 2 detachably arranged on the lower side of the panel 1, and a metal reinforcement 3 is embedded in the interior of the panel 1, and each supporting foot 2 All are cuboid, and the four sides of each supporting foot 2 are all inwardly recessed to form a first groove 21, and the four sides of each supporting foot 2 are formed with reinforcing ribs 22, and the reinforcing ribs 22 and the first groove 21 The bottom of the groove smoothly transitions through the arc.

[0031] There is a detachable structure between the panel 1 and the support foot 2, and the support foot 2 and the panel 1 can be assembled at will, which can meet different storage requirements, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com