End face grabbing mechanism of intelligent paper tube bagging machine

A grasping mechanism and tube bagging technology, applied in the field of paper tubes, can solve the problems of easy stacking and easy falling of paper tubes, and achieve the effect of avoiding mutual stacking, avoiding falling, and being easy to grasp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

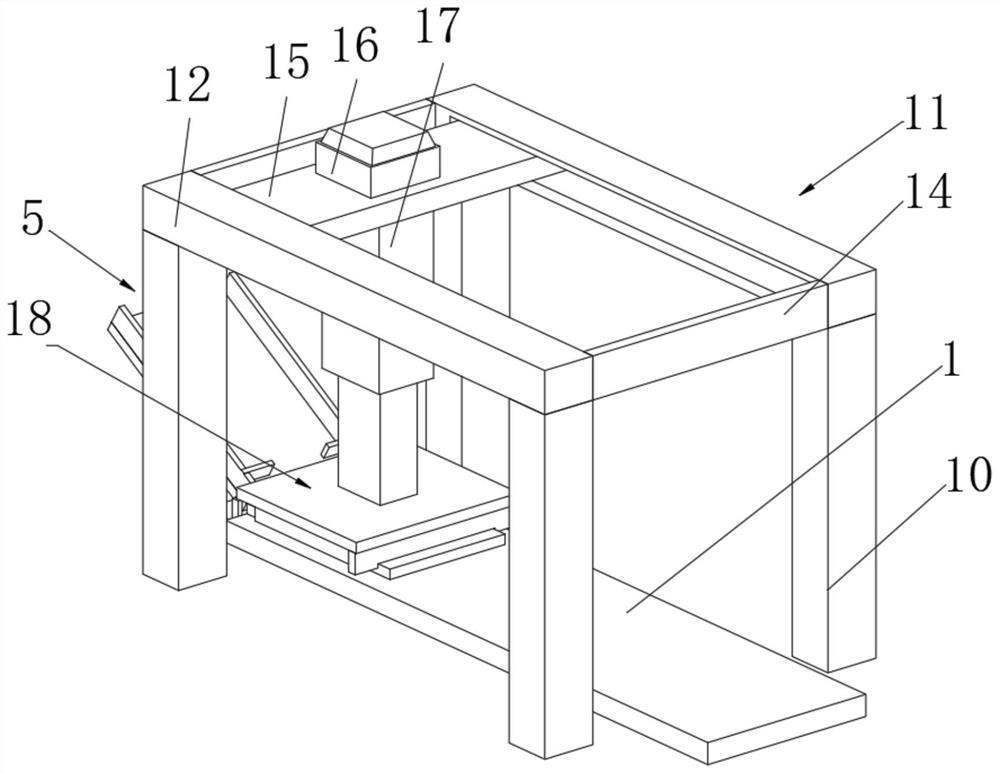

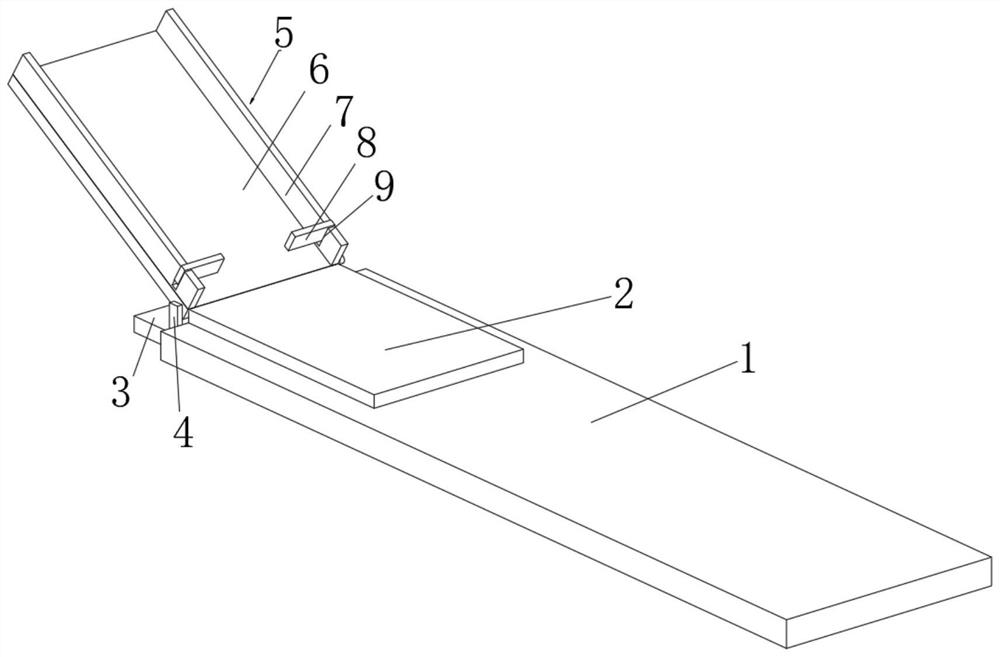

[0029] see Figure 1-6 , the present invention provides a technical solution: an end surface grabbing mechanism of an intelligent paper tube bagging machine, including a workbench 1 and a support frame 10, the upper end of the workbench 1 is provided with a bearing plate 2 near one side, and the workbench 1- The side position is provided with a support plate 3, and the upper end of the support plate 3 is provided with a vertical support 4 close to both sides. A conveying mechanism 5 is provided between two sets of vertical supports 4, and a transmission mechanism 11 is provided at the upper end of the four sets of support frames 10.

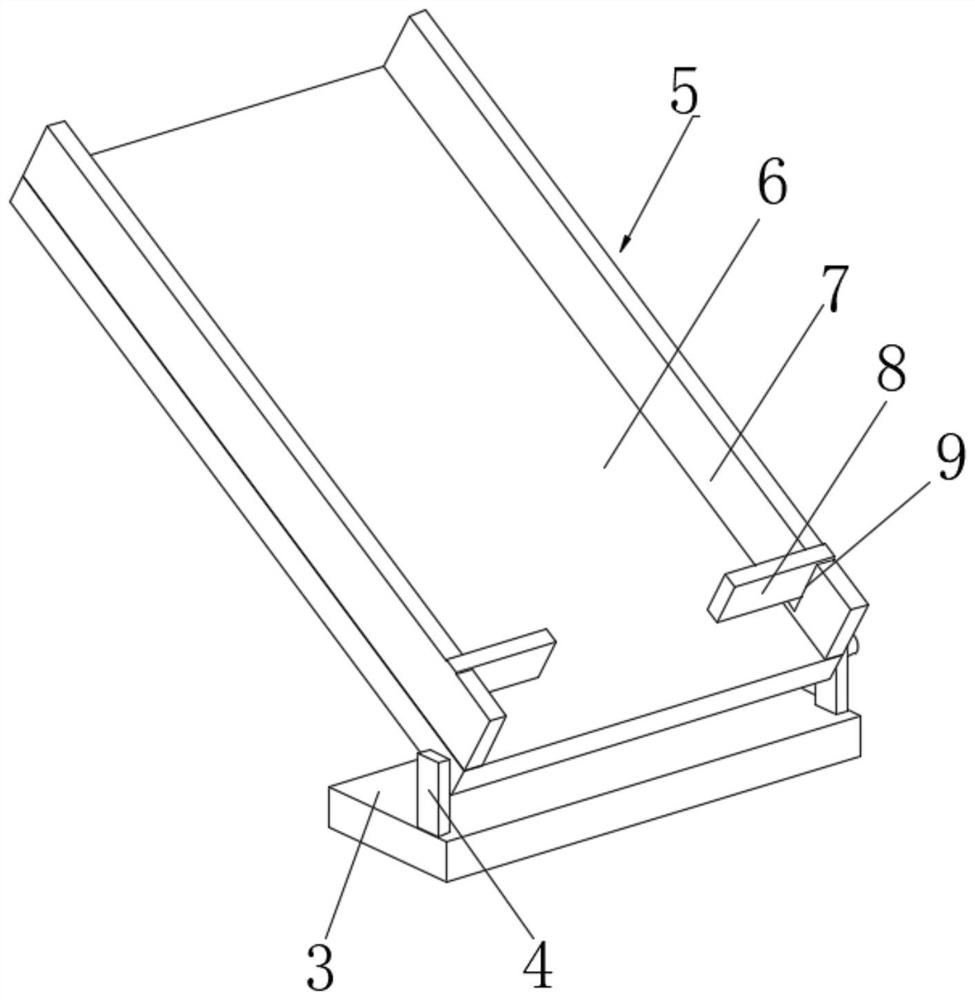

[0030] see image 3 The conveying mechanism 5 includes a guide plate 6, the side walls of the guide plate 6 are provided with protective plates 7 close to both sides, the upper end of the protective plate 7 is provided with a movable groove 9 near the position of the workbench 1, and a stopper is provided between the inner walls of the movable gr...

Embodiment 2

[0034] see Figure 4-6 , the present invention provides a technical solution: an end surface grabbing mechanism of an intelligent paper tube bagging machine, including a workbench 1 and a support frame 10, the upper end of the workbench 1 is provided with a bearing plate 2 near one side, and the workbench 1- The side position is provided with a support plate 3, and the upper end of the support plate 3 is provided with a vertical support 4 close to both sides. A conveying mechanism 5 is provided between two sets of vertical supports 4, and a transmission mechanism 11 is provided at the upper end of the four sets of support frames 10.

[0035] see Figure 5 , the clamping mechanism 18 includes a load bearing plate 19, the bottom of the load bearing plate 19 is provided with a limit plate 20 near one side, the bottom end of the limit plate 20 is provided with a groove 21 that matches the load plate 2, and the bottom of the load plate 19 End is provided with sliding groove 22 nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com