Air conditioner

A technology of an air conditioner and a shunt, which is applied in the field of air conditioners and can solve the problem of uneven distribution of refrigerants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

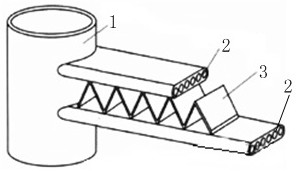

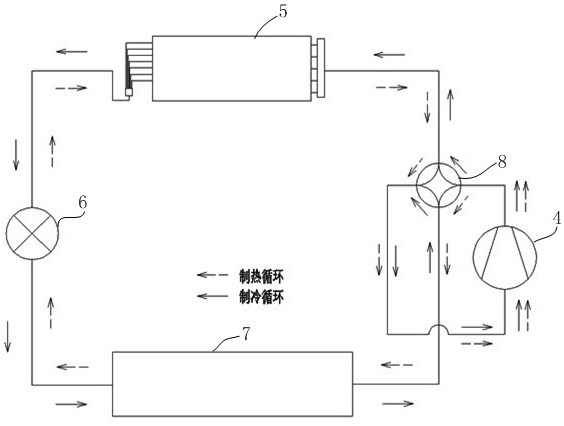

[0068] refer to Figure 4 to Figure 6 , an air conditioner in this embodiment includes a multi-flat tube parallel flow heat exchanger 10, and the multi-flat tube parallel flow heat exchanger 10 includes a plurality of flat tubes 100 and is used to evenly distribute the gas-liquid two-phase refrigerant to multiple Of course, the flow divider 200 in the flat tube 100 also includes fins 300 .

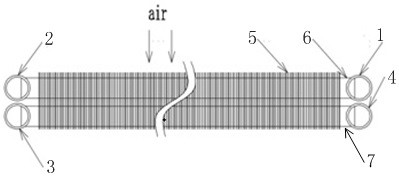

[0069] A plurality of flat tubes 100 are arranged at intervals up and down along the height direction of the multi-flat tube parallel flow heat exchanger 10 , and the distance between two vertically adjacent flat tubes 100 is 10-18mm. A plurality of micro-channels for circulating refrigerant are formed in the flat tube 100, and the flat tube 100 is penetrated in the fin 300, and the flow direction of the air flowing through the fin 300 is mutually related to the flow direction of the refrigerant flowing through the flat tube 100. Vertically, the heat / cold released by the refrigerant in th...

Embodiment 2

[0098] refer to Figure 14 to Figure 20 , in this embodiment, for the convenience of description, the side of the flat flow channel 211 that communicates with the refrigerant inlet 220 is defined as the first side 211A in the thickness direction of the flat flow channel 211, and the other side that communicates with the refrigerant outlet 230 is the flat side. The second side surface 211B in the thickness direction of the channel 211 .

[0099] The difference from Embodiment 1 is that along the extending direction of the flat channel 211 in this embodiment, the first side 211A in the thickness direction consists of the first sub-side 211A1 located on one side of the refrigerant inlet 220 and the first sub-side 211A1 located on the other side of the refrigerant inlet 220 . The first sub-side 211A1 and the second sub-side 211A2 are both inclined to the side where the refrigerant inlet 220 is located.

[0100]The reason for this design is that when the high-speed gas-liquid two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com