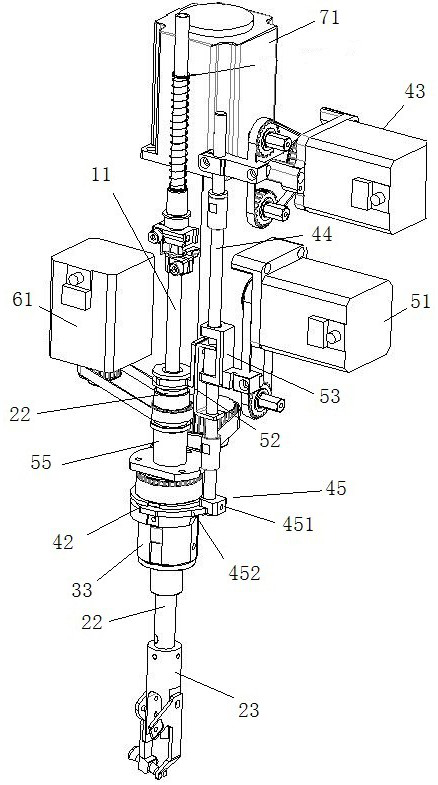

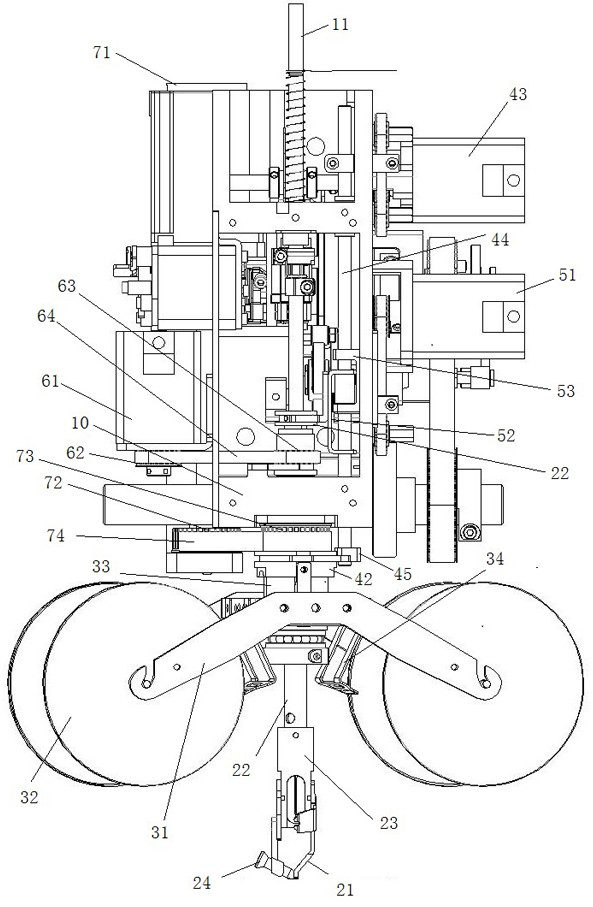

Tapping embroidery device and taping embroidery feeding control method

A tape embroidery and material feeding technology, which is applied in the tape embroidery device and the field of tape embroidery feeding control, can solve the problems of embroidery drawing deformation, large mechanical pulling force of the embroidery frame, bad embroidery, etc., and achieve the effect of simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

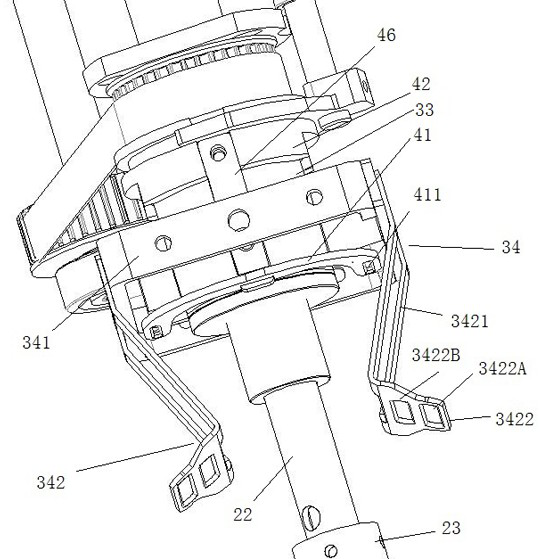

[0051] figure 1 , 2 The specific structure of the conveying frame 34 is shown, and the conveying frame 342 includes a first slant plate 3421 inclined downward from the side of the material tray 32 to the side of the presser foot sleeve 22, and from the side of the presser foot sleeve 22 to the side of the material tray 32. The second sloping plate 3422 that slopes sideways downward. One end of the first slanting plate 3421 is connected to the general installation frame 341 , and the other end is connected to the second slanting plate 3422 . The second sloping plate 3422 is provided with conveying holes. The feeding rack adopts lifting mode, its structure is as follows: figure 2 As shown in , the feeding frame is an annular structure with an opening, which is arranged around the feeding sleeve 42 . The feeding frame 41 is fixedly connected to the feeding sleeve through a vertical feeding connector 46, and the feeding frame is horizontally arranged relative to the needle pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com