Inorganic mixture prepared from construction waste recycled aggregate and preparation method thereof

A technology for recycling aggregate and construction waste, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as inability to meet demand, reduce construction waste requirements, improve economic benefits, and crush value reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

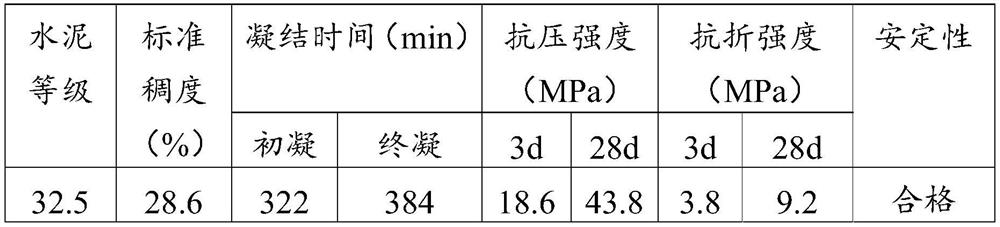

Embodiment 1

[0025] A kind of mixture made of construction waste recycled aggregate, which is composed of the following raw materials by weight percentage: 96wt% of recycled aggregate, 4wt% of cement, and the construction waste recycled aggregate is composed of the following raw materials by weight percentage: mortar and concrete 65wt%, Among them, the concrete accounts for 40.1wt% of the recycled aggregate content, 0.2wt% of sundries, and the rest are bricks and tiles. The needle flake content of the recycled aggregate is 1.8wt%, the mud content is 4.3wt%, and the micropowder content is 2.6wt%. .

Embodiment 2

[0027] A kind of mixture made of construction waste recycled aggregate, which is composed of the following raw materials by weight percentage: 95 wt% of recycled aggregate, 5 wt% of cement, and the recycled construction waste aggregate is composed of the following raw materials by weight percentage: 60 wt% of mortar and concrete, Among them, the concrete accounts for 42.1wt% of the recycled aggregate content, 0.3wt% of sundries, and the rest are bricks and tiles. The needle flake content of the recycled aggregate is 2.4wt%, the mud content is 4wt%, and the micropowder content is 2.8wt%.

Embodiment 3

[0029] A kind of mixed material made of construction waste recycled aggregate, which is composed of the following raw materials in weight percentage: 94wt% of recycled aggregate, 6wt% of cement, and the construction waste recycled aggregate is composed of the following raw materials in weight percentage: mortar and concrete 70wt%, Among them, the concrete accounts for 36.5wt% of the recycled aggregate content, 0.1wt% of sundries, and the rest are bricks and tiles. The needle flake content of the recycled aggregate is 1.5wt%, the mud content is 3.6wt%, and the micro powder content is 2.9wt%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com