Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the direction of off-road vehicle tires, tire parts, tire treads/tread patterns, etc., can solve the problems of uniformity, easy deterioration of weight balance, uniformity, and influence of weight balance, etc., and achieve improvement Driving performance and traction improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

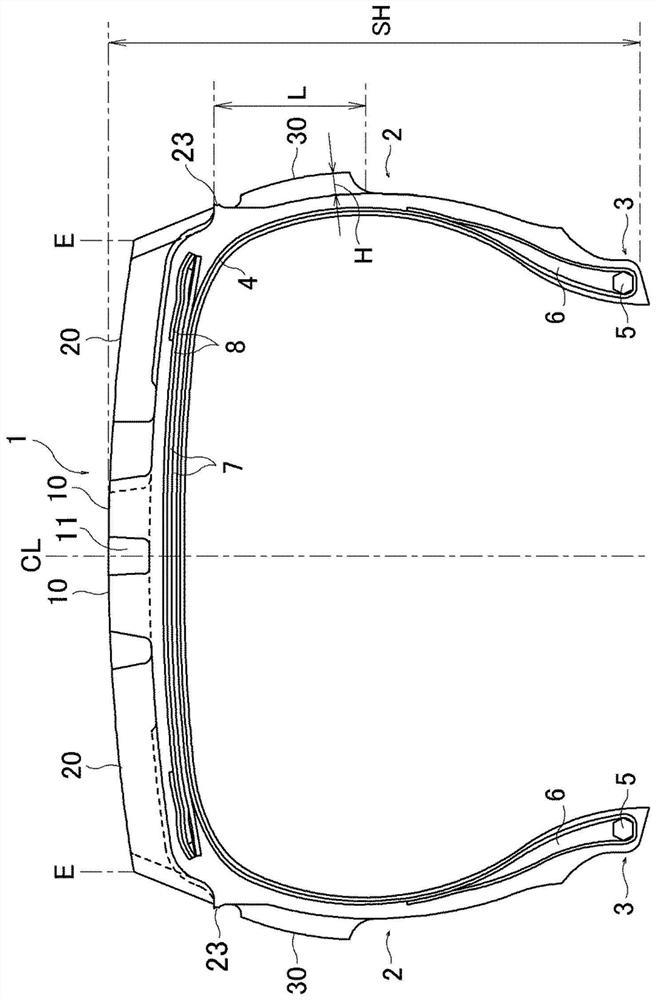

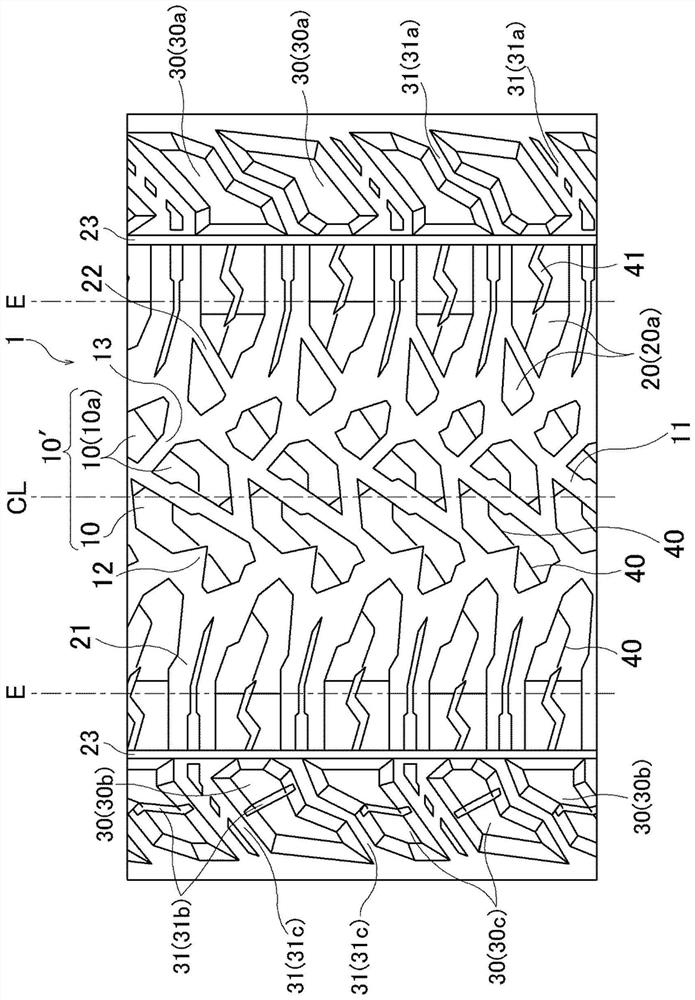

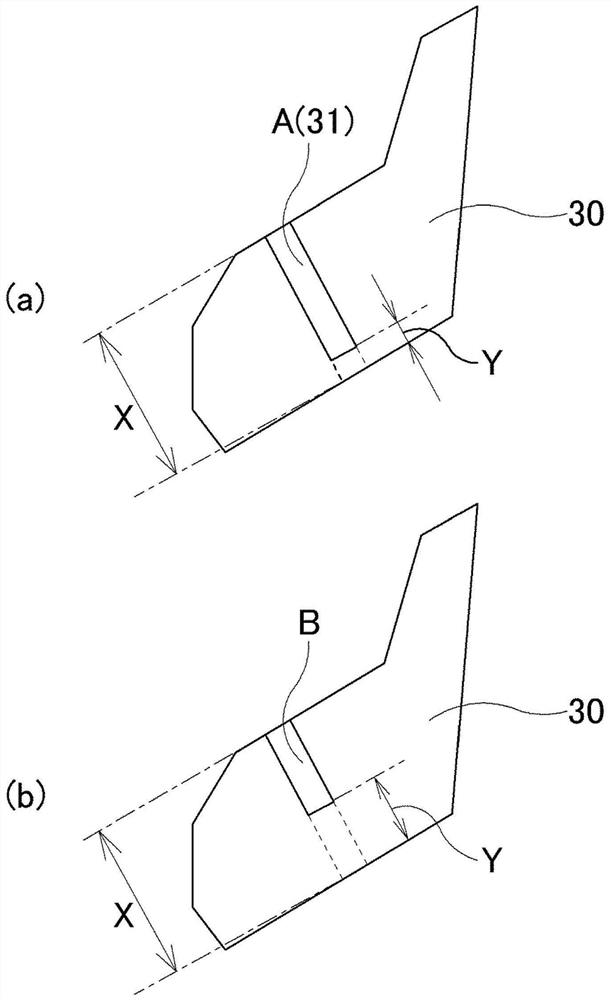

[0052] The tire size is LT265 / 70R17, with figure 1 The illustrated basic structure, with figure 2 The tread pattern is the basic tone, and the number N1 of sidewall blocks on one side of the tire equator, the land area TS1, the number N2 of sidewall blocks on the other side of the tire equator, the land area TS2, Ratio of the product of the total area SS1 of the sidewall block and the product of the land area TS1 to the product of the total area of the sidewall block SS2 and the product of the land area TS2 (SS1×TS1) / (SS2×TS2), the bulging height of the sidewall block , the ratio L / SH of the vertical distance L from the outermost end in the tire width direction of the tread portion to the innermost point in the tire radial direction of the sidewall region to the tire section height SH, the presence or absence of shallow groove regions, and the The ratio of the groove depth to the hump height H and the ratio of the total length of the shallow groove region to the overall le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com