Workshop production scheduling and analysis method based on scheduling rule

An analysis method and rule technology, applied in the field of heuristic workshop resource scheduling based on multiple constraints, can solve problems such as lack of analysis and exploration functions, and achieve the effect of improving delivery rate, meeting order requirements, and solving emergencies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

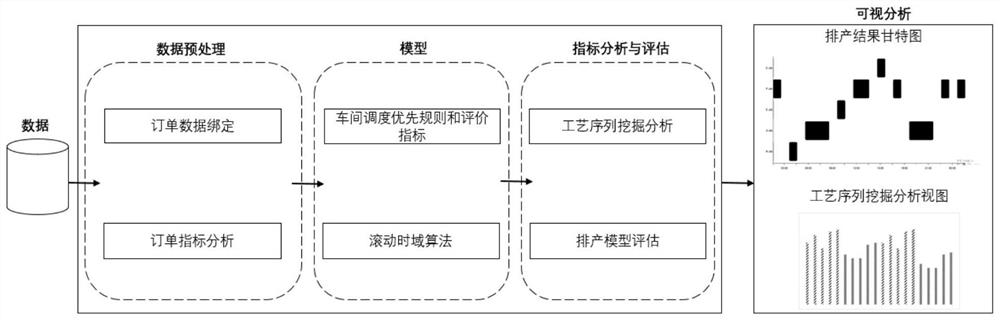

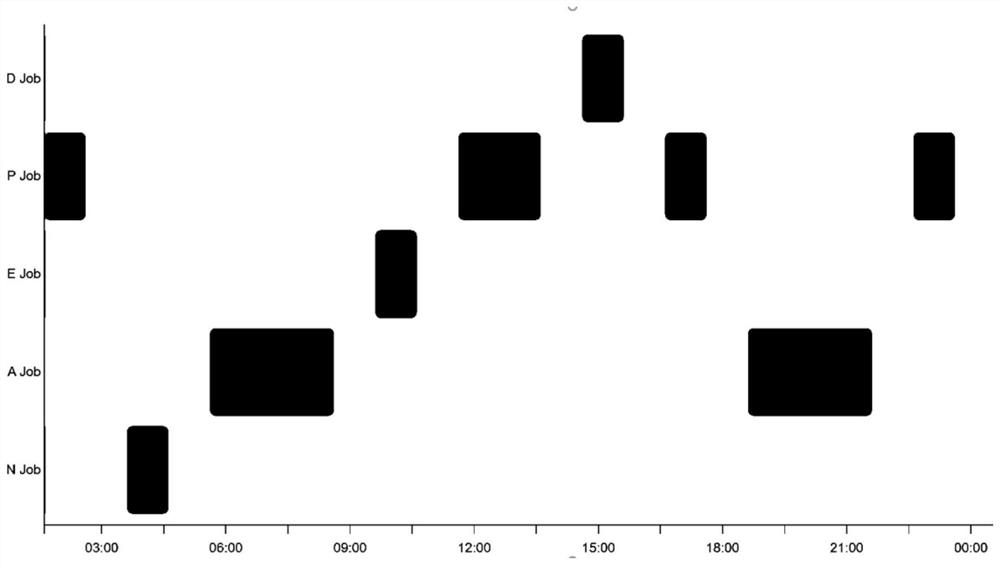

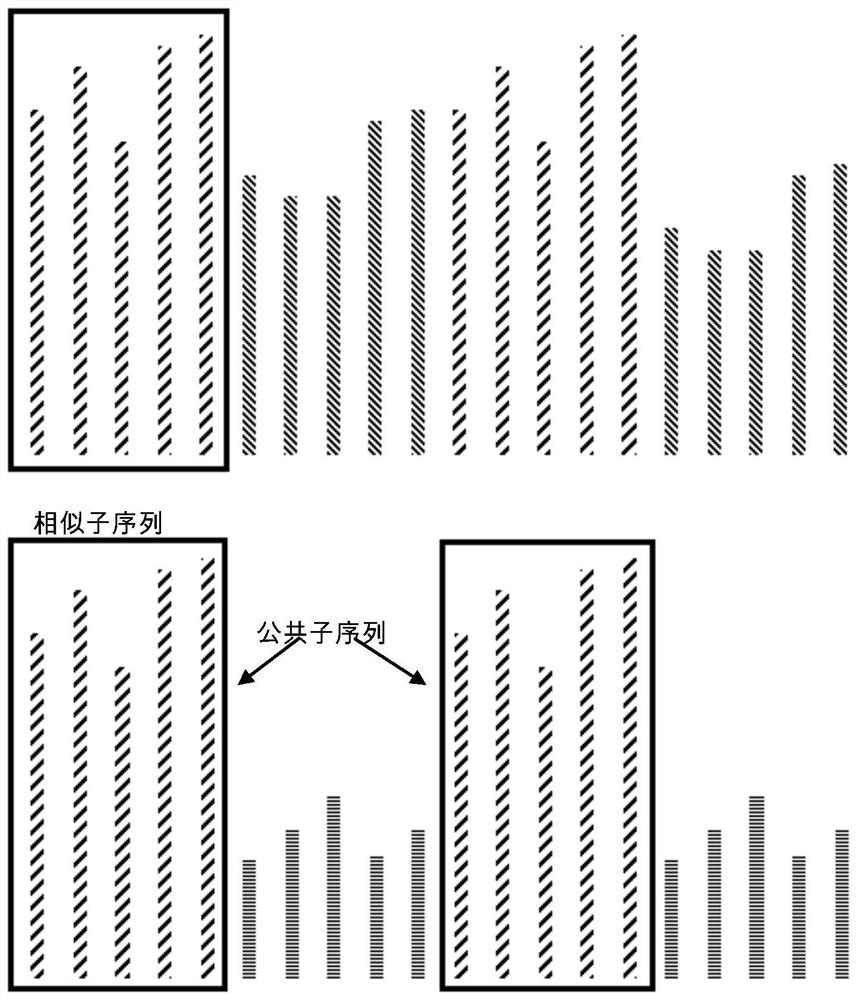

[0035] refer to Figure 1 ~ Figure 3 , a workshop scheduling and analysis method based on scheduling rules, including the following steps:

[0036] (1) Import order data information, bind the order-process-resource relationship, and analyze the indicators of different orders: bind the time requirement and quantity requirement with the order, and then retrieve the corresponding information from the order data to the product data Product technological process, delete other redundant technological processes and simplify their symbols, and then retrieve the corresponding manpower, equipment, and processing resource data from product data to resource data, and obtain the order-process-resource relationship comprehensively, and then Analyze indicators for different orders and give scores;

[0037] (2) Establish a mathematical model of production s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com