Multi-degree-of-freedom jumbolter system for full-section hard rock heading machine

A technology for hard rock roadheaders and rock bolters, which is applied in the installation of bolts, drilling equipment, and earthwork drilling and mining, and can solve the problems of limited construction space, large construction space requirements, and low construction efficiency of full-face hard rock roadheaders. , to achieve the effect of flexible operation mode, small footprint of equipment and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

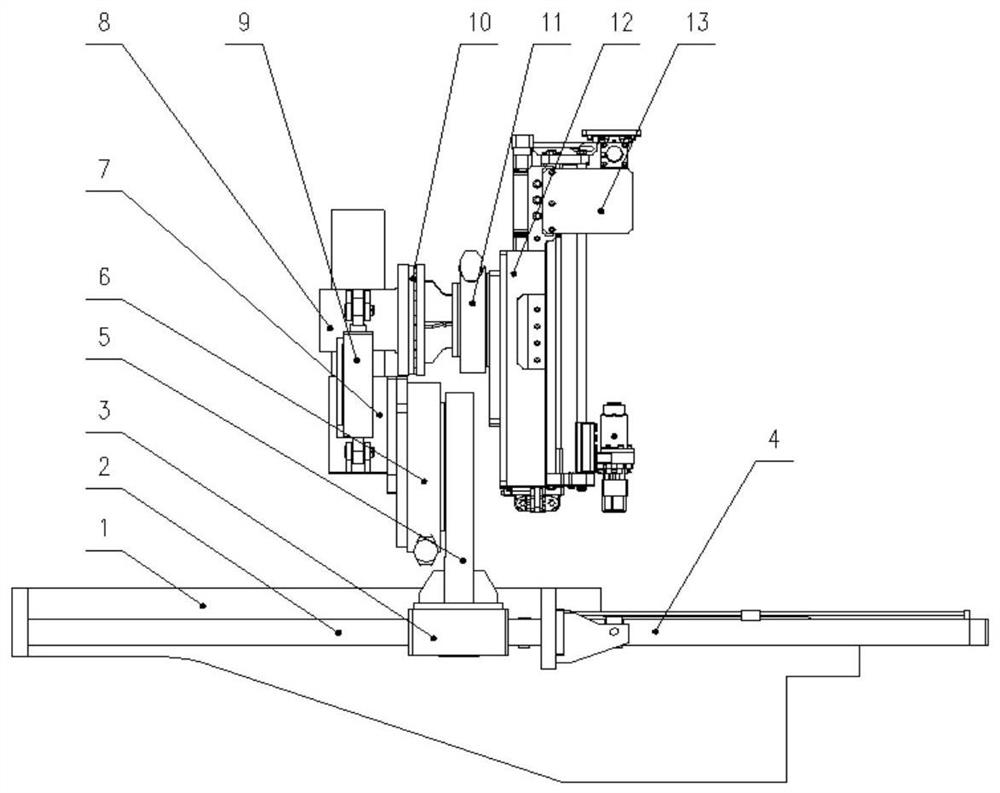

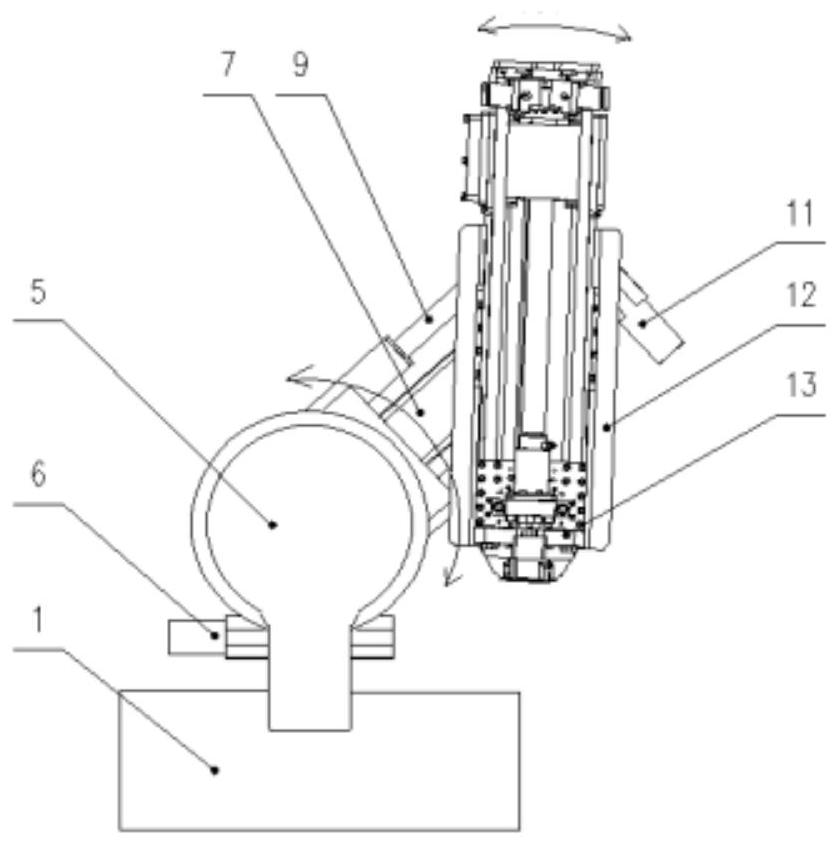

[0017] see Figure 1 to Figure 2 , the present invention provides a technical solution: a multi-degree-of-freedom rock bolt system for full-face hard rock boring machines, including a rock bolt base 1, a drill slideway 2, a drill slideway main frame 3, and a propulsion cylinder 4 , drilling rig tower head 5, sliding beam rotary reducer 6, drilling rig sliding beam 7, drilling rig rear axle seat 8, drilling rig lifting cylinder 9, diaphragm coupling 10, drilling rig rotary reducer 11, drilling rig support floor 12 and vertical drilling rig 13. A drill slideway 2 is fixedly installed on the base 1 of the rock bolter, a propulsion cylinder 4 is fixedly installed on the side of the base 1 of the rockbolt rig opposite to the slideway 2 of the drill rig, and a main slideway of the drill rig is installed slidingly on the slideway 2 of the drill rig. Frame 3, the piston rod of the propulsion oil cylinder 4 is fixedly connected with one end of the main frame 3 of the drilling rig slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com