Special odorless modified acrylic acid stoving varnish coating

A kind of acrylic and special technology, applied in the direction of coating, etc., can solve the problems of large solvent volatilization, irritating nose and eyes, and health damage of workers, etc., and achieve the effect of excellent impact flexibility and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A special modified acrylic varnish with clean odor, in parts by weight, including 60 parts of HE61, 11 parts of nano black paste, 0.5 part of fumed silica, 0.2 part of BYK333, 0.1 part of TEGO410, 0.2 part of TEGO245, 5.7 parts of DBE, 2 parts of Z-6040, 13 parts of Bayer 3175, 3 parts of Cytec 303, 0.3 parts of cooling agent and 4 parts of 704 epoxy resin.

[0024] A preparation method of a clean-odor type special modified acrylic varnish paint comprising the following steps:

[0025] Step 1: Adjust the speed of the dispersing machine to 800-1200rpm / min, put HE61, nano black paste, fumed silica, BYK333, TEGO410, TEGO245 and DBE into the dispersing tank according to the amount and stir thoroughly to obtain the mixture;

[0026] Step 2: Based on the above step 1, continue to put in Z-6040, Bayer 3175, Cytec 303, cooling agent and 704 epoxy resin in sequence, and keep stirring;

[0027] Step 3: Adjust paint viscosity;

Embodiment 2

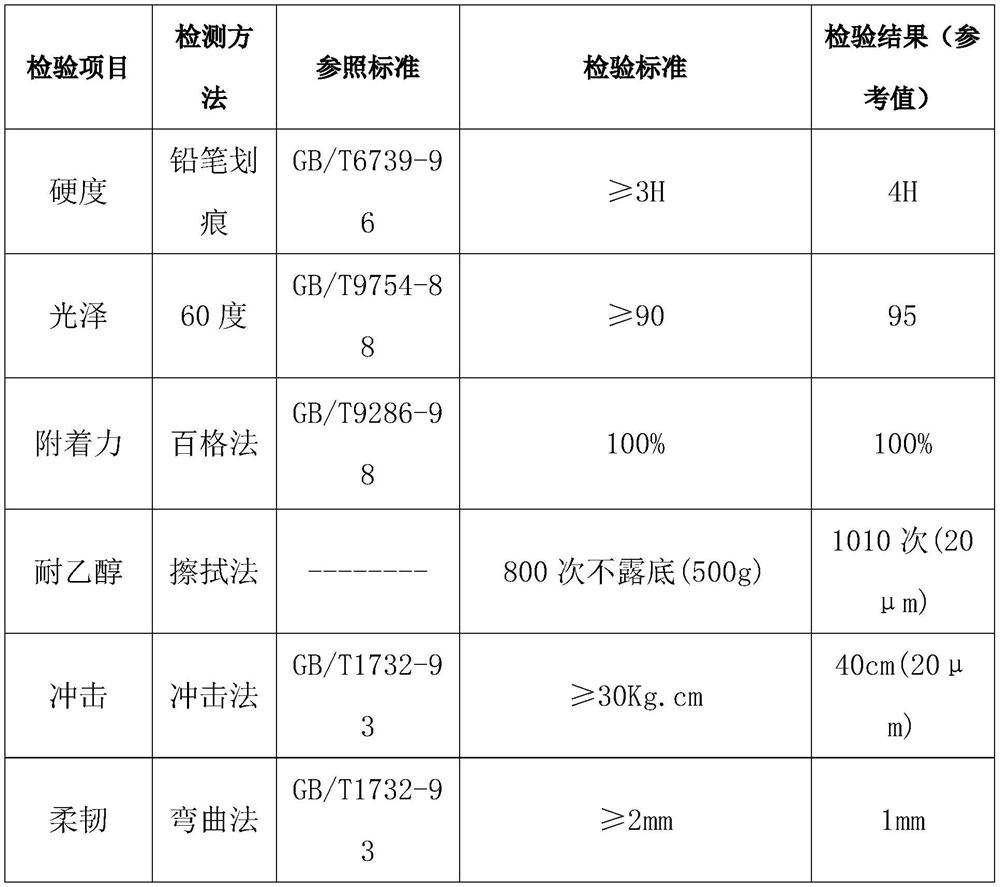

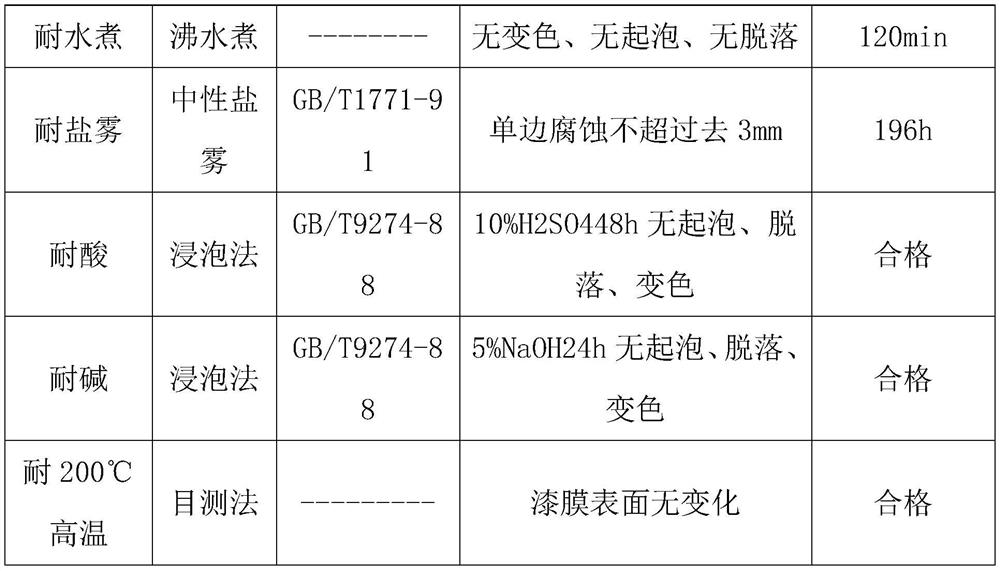

[0036] For the detection of the use effect of the net-odor special modified acrylic varnish paint prepared by the method of the present invention, the net-odor special modified acrylic varnish paint prepared by the method of the present invention is selected;

[0037] Construction process conditions: paint viscosity coating 2#14 / second Baking process: 180℃×30min

[0038] Substrate: tinplate

[0039]

[0040]

[0041] It can be seen from the above table that the odor-cleaning special modified acrylic varnish baking varnish prepared by the method of the present invention performs well in each detection index, and has a strong promotional value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com