Assembly cleaning device for photovoltaic panel production

A cleaning device and technology for photovoltaic panels, applied in cleaning methods using tools, cleaning methods using liquids, cleaning flexible objects, etc., can solve problems such as poor effect of photovoltaic panel components, doping with impurities, and blockage of water pipelines. Achieve simple structure, improve cleaning efficiency and improve filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

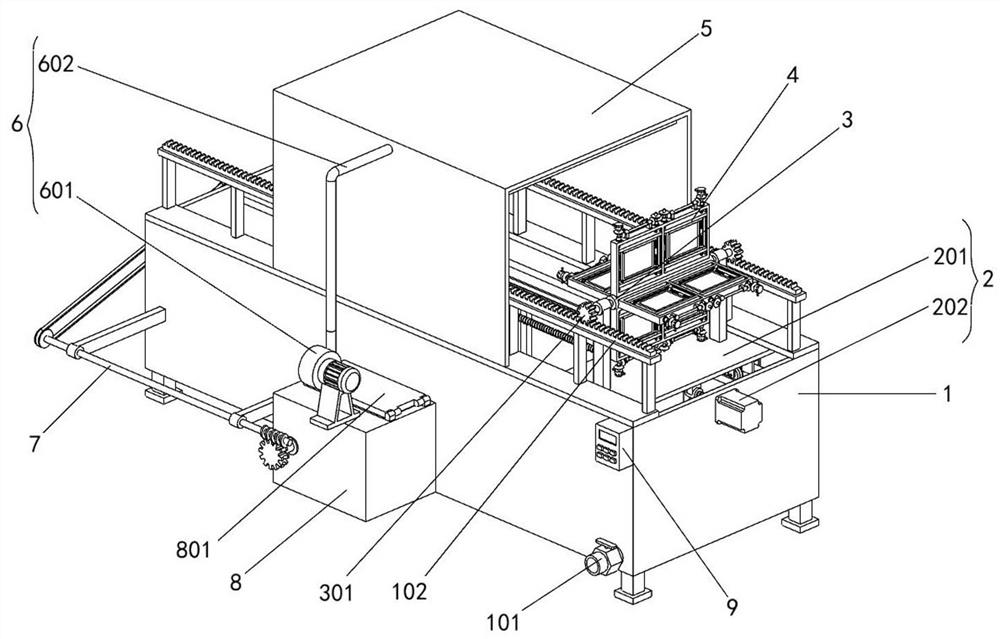

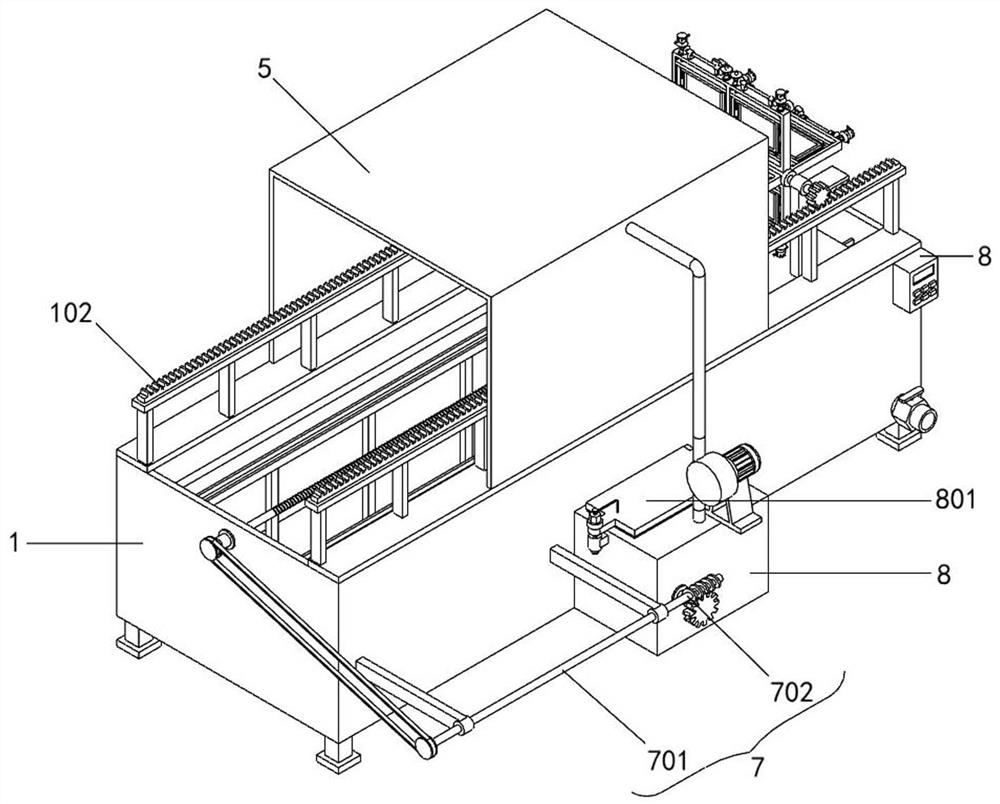

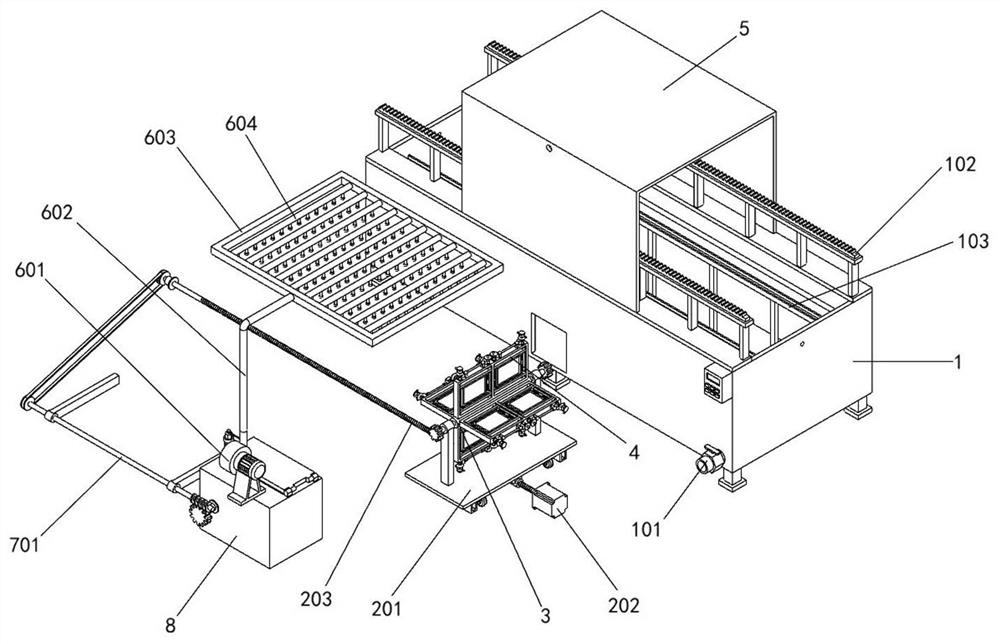

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The present invention provides a component cleaning device based on photovoltaic panel production, which includes: a box body 1; a moving part 2 is provided on the upper side of the box body 1 to drive the rotating part 3 to move left and right in the box body 1, and the box body 1 There is a sewage discharge pipe 101 on the lower right side of the front end, and a valve is installed on the sewage discharge pipe 101, and a fixed rack 102 is fixed on both sides of the front and back of the upper end of the box body 1, which is used for meshing with the driving gear 301; the box body 1 Two support slide rails 103 and two support slide bars 104 are fixed on the inner upper end symmetrically front and back, and the upper parts of the two support slide bars 104 slide with a moving part 2, so that the moving part 2 can effectively guide when moving;

[0037] The moving part 2 comprises a moving plate 201, a driving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com