A fan mesh cover processing device

A processing device and fan net cover technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as difficult cleaning and processing, dead angles, and inability to contact the fan net cover, so as to promote Effects of disengagement, avoidance of obstruction, and avoidance of overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

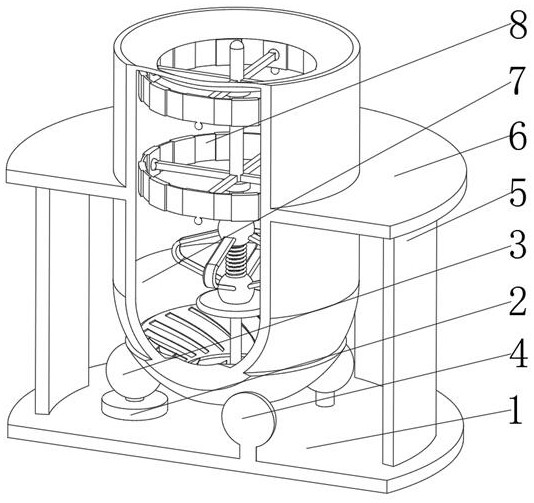

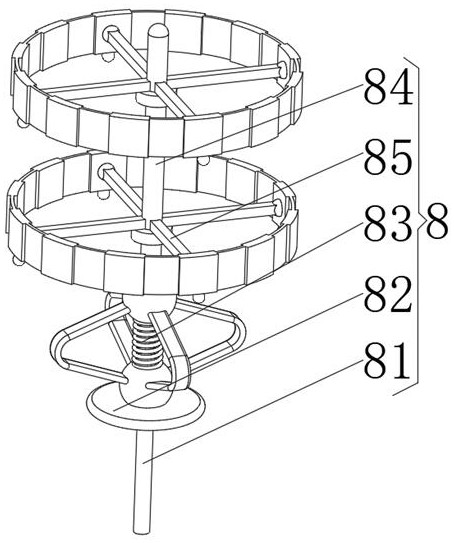

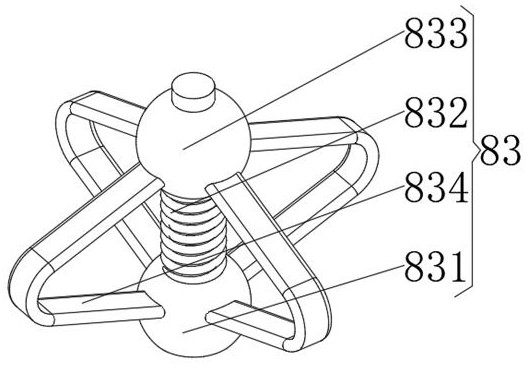

[0037] see Figure 1-5 , the present invention provides a technical solution: a fan net cover processing device, specifically comprising:

[0038]Base plate 1, the base plate 1 has a circular seat plate, and a drive motor 2 installed in the middle of the top of the circular seat plate, and a friction ball 3 installed on the top of the drive motor 2, and the top of the circular seat plate And the support rotating ball 4 that becomes equilateral triangular position with drive motor 2, and the fixed frame 5 that is installed on the top of the circular seat plate and is positioned at the outside of drive motor 2, and the operating panel 6 that is installed on the top of fixed frame 5, and is installed on The processing cylinder 7 at the middle position of the operation panel 6, and the processing device 8 installed at the middle position of the inner cavity bottom of the processing cylinder 7, contact the processing cylinder 7 through the setting of the friction rotating ball 3 an...

Embodiment 2

[0050] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: a method for using a fan grille processing device, comprising the following steps,

[0051] Step 1: Place the fan guard on the fixing fork 852, and install the carrying device 85 and the fan guard on the surface of the separating pole 84 as a whole, and fix them;

[0052] Step 2: inject water into the processing cylinder 7 in the equipment, so that the water submerges the fan guard;

[0053] Step 3: Start the driving motor 2 to make the friction ball 3 rotate, and use the friction to drive the rotation loop 72 to rotate, and then make the flow concentrating fan plate 73 rotate;

[0054] Step 4: The flow converging fan plate 73 drives the water flow to rotate to form a vortex water flow, so that the water flow can wash and clean the fan net cover;

[0055] Step 5: The centrifugal force generated by the rotation of the water impacts the weight ball 857, the clamp plate 854...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com