Optical engine

An optical engine and light source technology, applied in the field of optical engines, can solve the problems of reducing the effect of lens transmission imaging, red light and green light do not meet the requirements, and affect the conversion efficiency of fluorescent layer 1, so as to ensure conversion performance and avoid transmission imaging The effect is poor, and the effect of ensuring the effect of transmission imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present application clearer, a light source using a fluorescent wheel is introduced next.

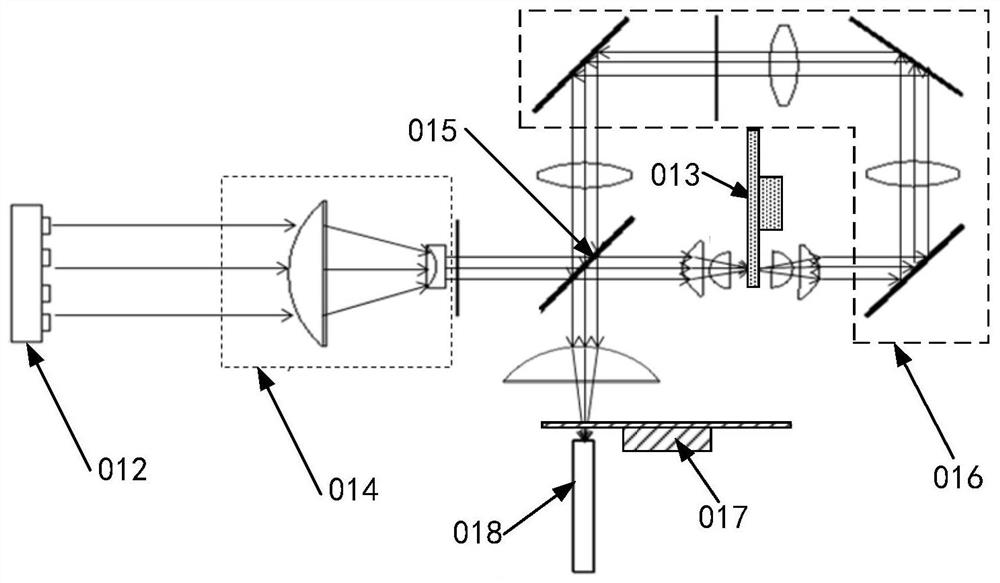

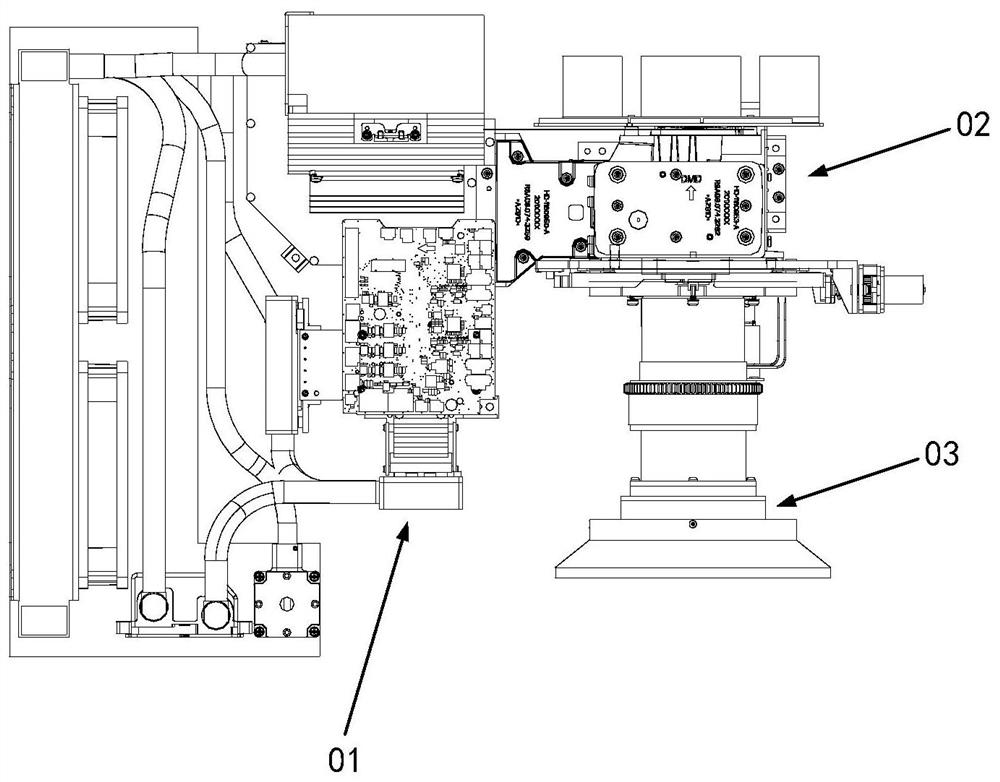

[0048] Such as figure 2 As shown, the light source 01 includes a light-emitting device 012, a fluorescent wheel 013, a light-condensing assembly 014, a dichroic mirror 015, a mirror assembly 016, a color filter 017, and a homogenizer 018; wherein, the light-emitting device 012, the light-condensing assembly 014 , the dichroic mirror 015 and the fluorescent wheel 013 are sequentially arranged along the same straight line, the light exit port of the light emitting device 012 faces the light incident side of the light concentrating component 014, the light exit side of the light concentrating component 014 faces the transmission surface of the dichroic mirror 015, and The plane where the dichroic mirror 015 is located forms an included angle with the center line of the incident beam, the light incident side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com