Nuclear power plant buried hydrogen pipeline leakage monitoring system and method

A technology for monitoring systems and nuclear power plants, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as hydrogen leakage, hydrogen monitoring devices alarming for no reason, unable to locate, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

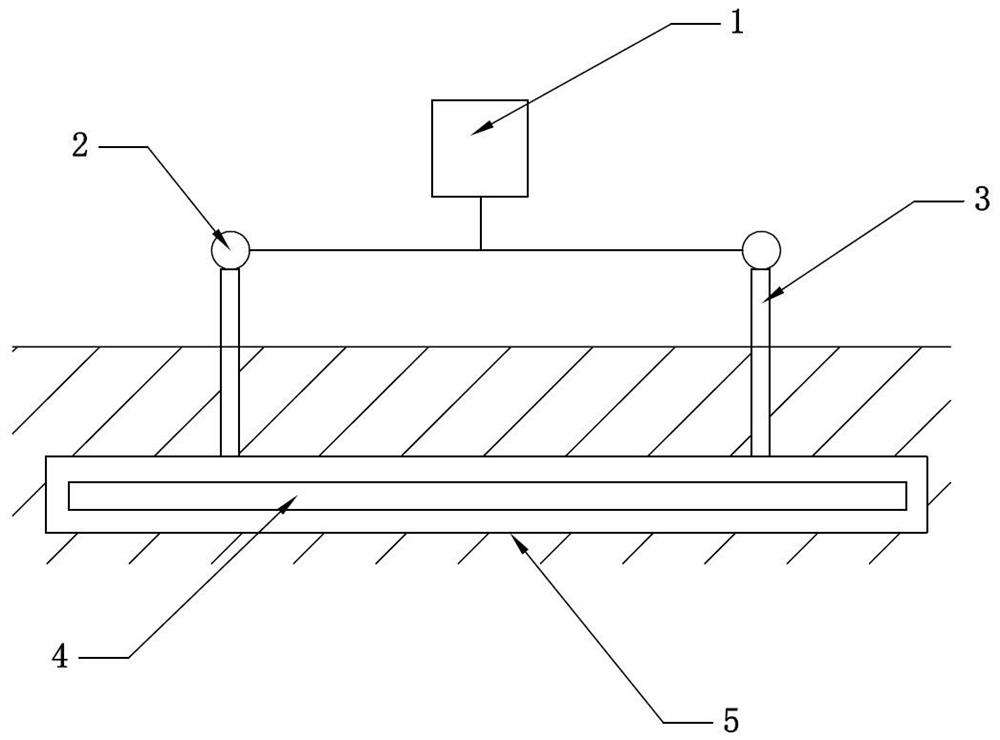

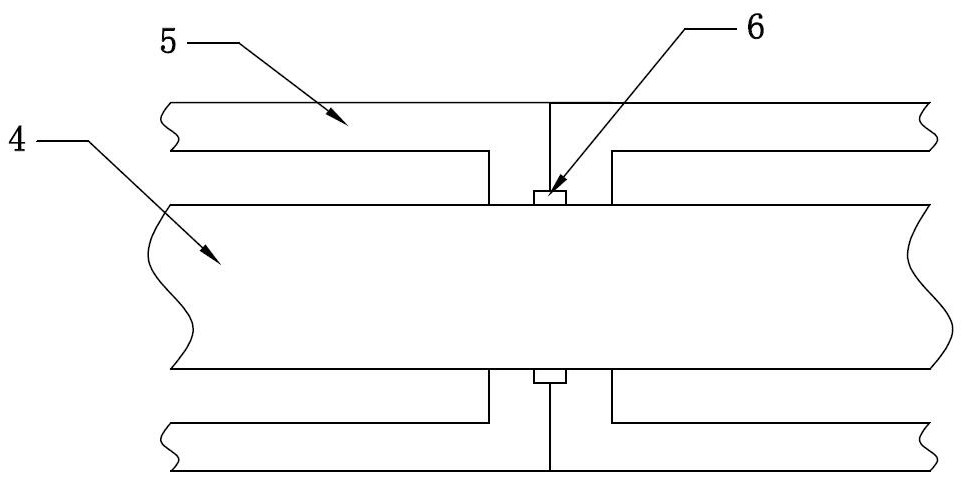

[0032] In this embodiment, a nuclear power plant buried hydrogen pipeline leakage monitoring system, such as figure 1 , figure 2 As shown, it includes a sleeve 5, a hydrogen concentration probe 2 and a control unit 1. The hydrogen pipeline 4 is arranged in the sleeve 5. The end surface of the sleeve 5 is provided with a through hole and a sealing groove. The diameter of the through hole is the same as that of the hydrogen pipeline. The groove is arranged around the through hole, and a sealing ring 6 is arranged in the sealing groove, and two adjacent casings share a sealing ring 6. Under the action of the sealing ring, the casing and the hydrogen pipeline form a closed space, so that there is no hydrogen leakage When there is no air flow inside the casing. The casing 5 is provided with a vertical pipe 3, the vertical pipe 3 is arranged at both ends of the casing, the hydrogen concentration probe 2 is arranged at the upper end of the vertical pipe 3, the hydrogen concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com