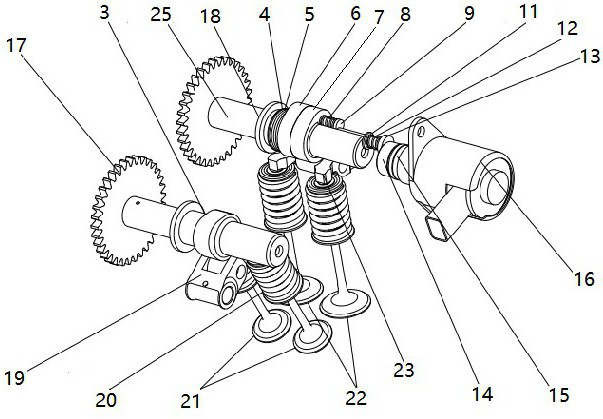

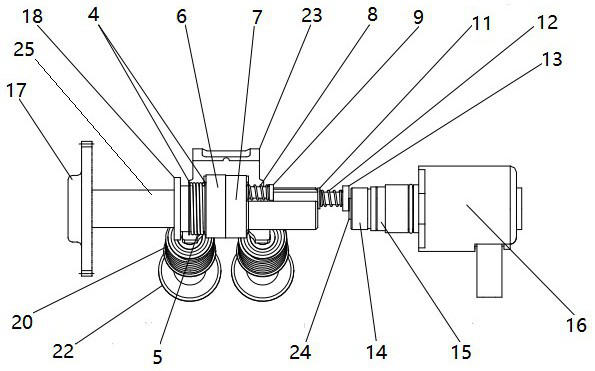

Variable valve mechanism for motorcycle engine with double overhead camshafts

A valve train, camshaft technology, applied in engine components, machines/engines, valve devices, etc., can solve the problems of enlarged space and reduced accuracy of cam control rocker arms, and achieve sound elimination, high structural control accuracy, and space. compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The structure of Example 1 is still as Figure 1 ~ 7 As shown, the connection relationship is no longer described, and it is now introduced that it is configured, a motorcycle engine variable gas mechanism for having a double top camshaft, mainly including:

[0049] The cylinder head 1 is used to fix and mount the camshaft front block 2, the exhaust cam shaft 3, the intake cam shaft 25, the camshaft rear cover 10, the positioning sleeve B14, the oil seal 15 and the electromagnet 16;

[0050] Camshaft front block 2 for fixing the exhaust camshaft 3 and the low speed intake camshaft;

[0051] The exhaust cam shaft 3 is used to drive the exhaust gas rocker arm 19, the valve spring 20, the exhaust door 21, and the type line of the exhaust cam is regularly discharged;

[0052] Part A4, a total of two, one mounted between the cam axial compression cover 2 and the friction spring 5, and the other is mounted between the friction spring 5 and the high-speed intake cam 6, and the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com