Air conditioner air supply system and method for rail transit vehicle

A technology for rail transit vehicles and air supply systems, applied in the field of air-conditioning air supply systems, can solve the problems of high noise, single return air position, uneven return air, etc., and achieve the effects of reducing power consumption and reducing return air noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

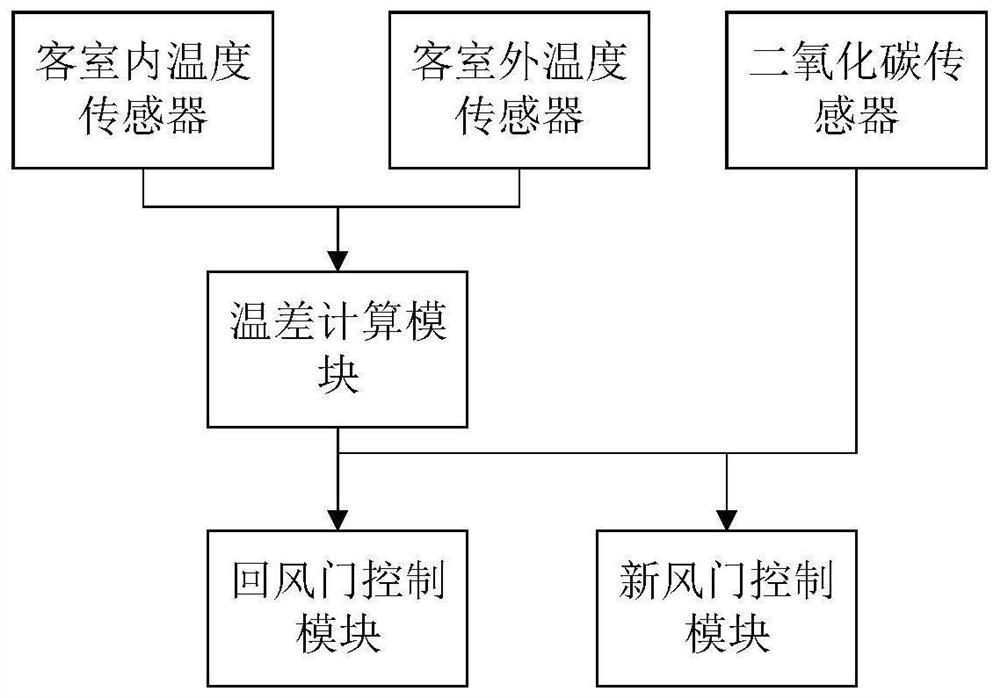

[0037] Embodiment 1 is basically as attached figure 1 Shown:

[0038] An air-conditioning air supply system for a rail transit vehicle, comprising a passenger interior temperature sensor, a passenger exterior temperature sensor, a return air door control module, and a fresh air door control module. The temperature sensor inside the passenger room is used to detect the temperature inside the passenger room; the temperature sensor outside the passenger room is used to detect the temperature outside the passenger room. The temperature sensor in the passenger room is set on the air return door and the air return port, and the air return port is located in the gap of the air duct. The return air position of the air conditioner in the existing rail transit vehicles is single, and the return air speed is relatively fast, resulting in large return air noise. In the present invention, the return air is carried out by utilizing the space of the air duct in the passenger room, and the ...

Embodiment 2

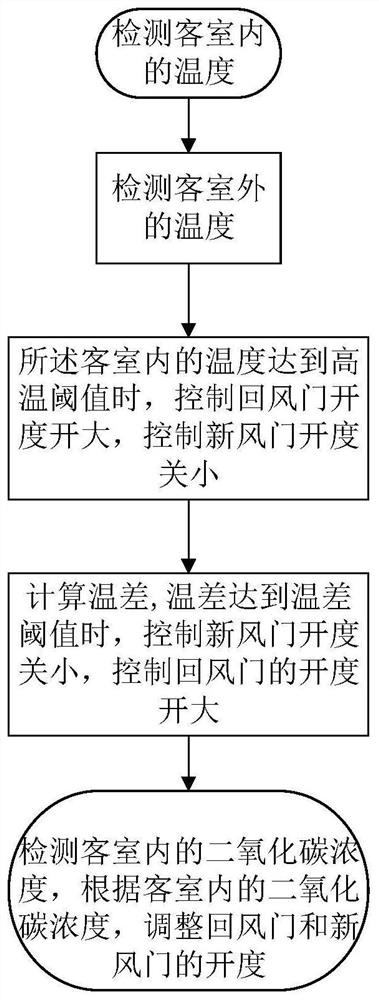

[0045] Embodiment 2 is basically as attached figure 2 Shown:

[0046] An air-conditioning air supply method for a rail transit vehicle, comprising the following steps:

[0047] S1: Detect the temperature in the passenger room through the temperature sensor in the passenger room; the temperature sensor in the passenger room is set at the air return door and the air return port; the air return port is located in the gap of the air duct;

[0048] S2: Detect the temperature outside the passenger room through the temperature sensor outside the passenger room;

[0049] S3: Control the opening of the return air door and the fresh air door; when the temperature in the passenger compartment reaches a high temperature threshold, control the opening of the return air door to be large, and control the opening of the fresh air door to be small.

[0050] The opening degrees of the return air door and the fresh air door include full opening, 2 / 3 opening, 1 / 3 opening and full closing. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com