Windscreen wiper motor rotor snap spring mounting device

A technology for a motor rotor and an installation device, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of unstable installation position of the circlip, low installation efficiency of the circlip, and poor installation effect of the circlip. Speed up installation efficiency, accurate installation, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

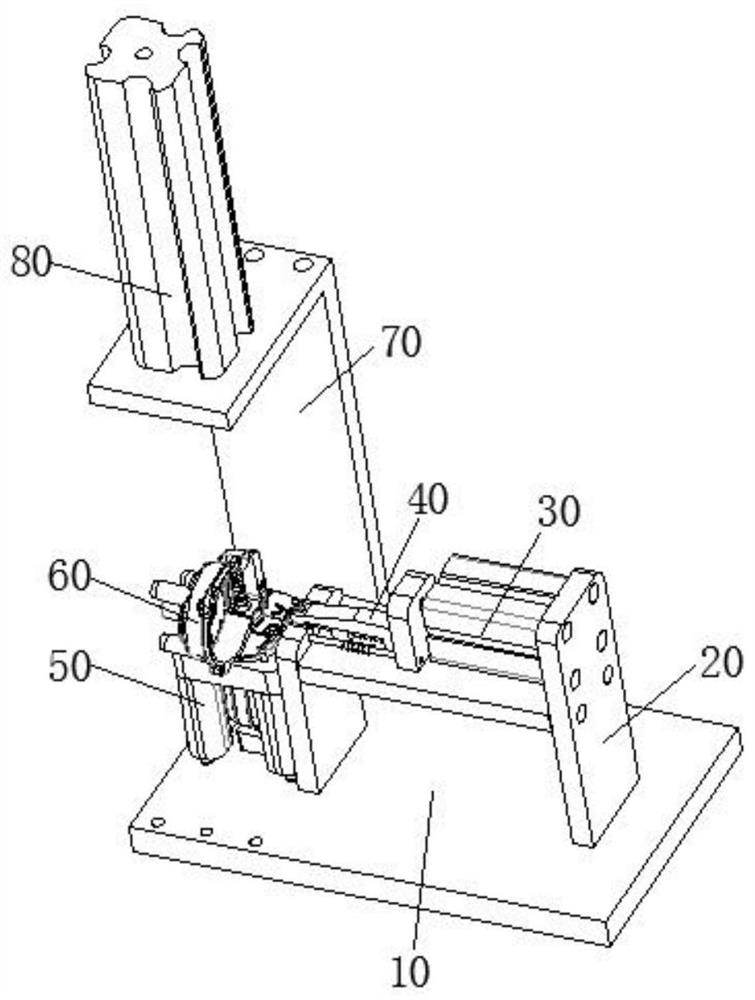

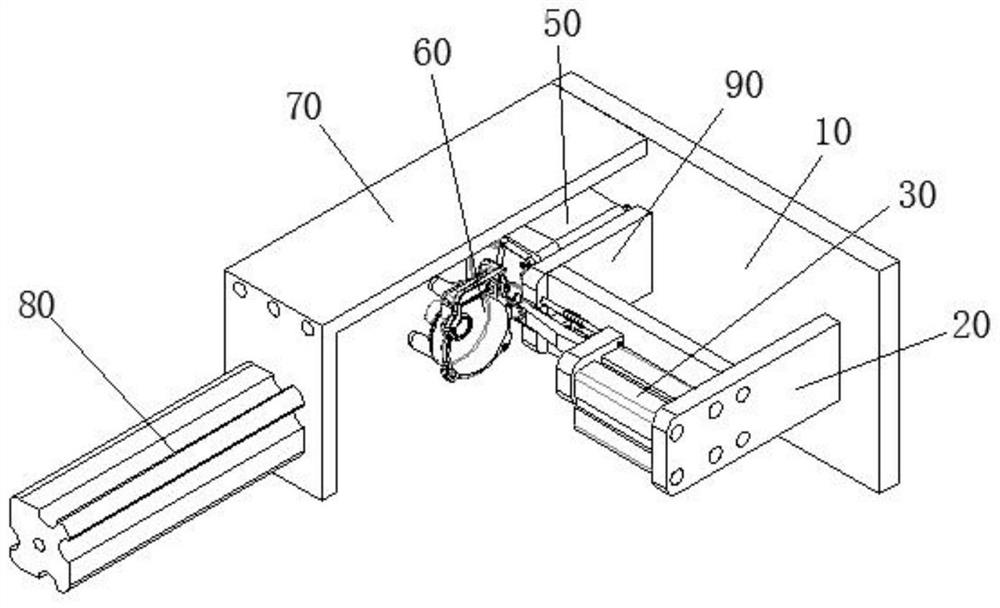

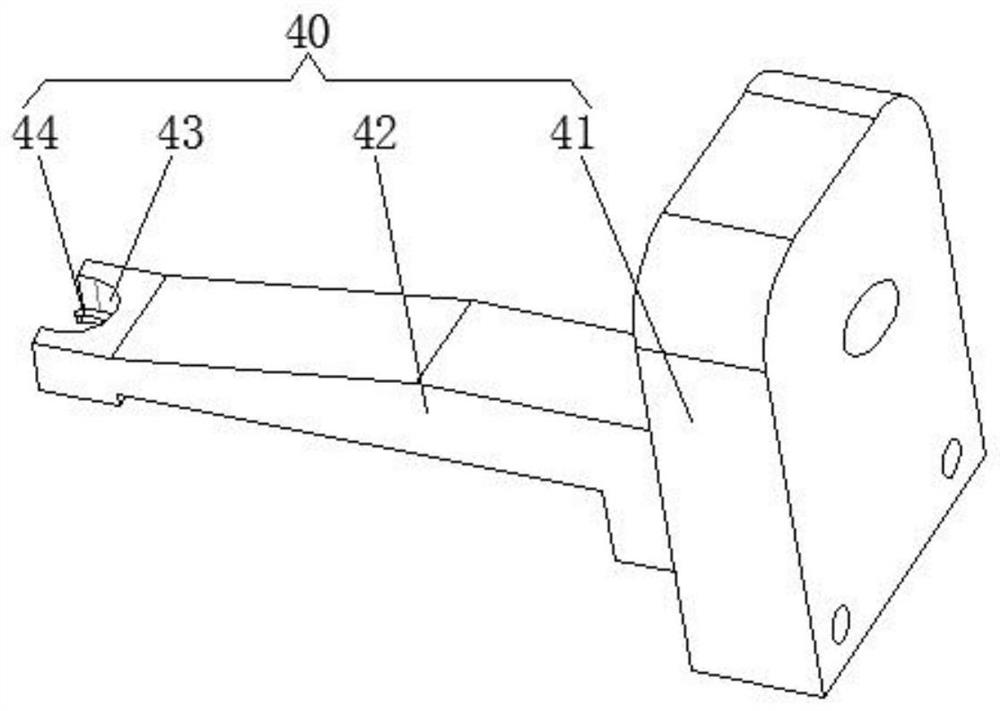

[0021] Such as Figure 1-2 As shown, the wiper motor rotor circlip installation device described in this embodiment includes a horizontal base 10, a fixed plate 20, a clip 40, a motor housing placement mechanism 50, and a motor housing 60. The top of the horizontal base 10 is A fixed plate 20 is fixed on one side, and the other side of the top of the horizontal base 10 is provided with a motor housing placement mechanism 50, a motor housing 60 is placed on the motor housing placement mechanism 50, and a motor housing 60 is fixed on the fixed plate 20. Pushing mechanism, the output end of the pushing mechanism is provided with a clamping part 40, the clamping part 40 clamps the circlip and moves to the inside of the motor housing 60, and the horizontal base 10 is located above the motor housing 60 A limit mechanism is provided to limit the position of the motor housing 60 , and the limit mechanism clamps the rotor to be inserted into the motor housing 60 .

[0022] The push me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com