Crystal film screen

A single crystal, transparent film technology, applied in the direction of identification devices, instruments, etc., can solve the problems of low light transmittance, large power box, small size of crystal film screen, etc., achieve high light transmittance, convenient transportation, installation, maintenance and installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

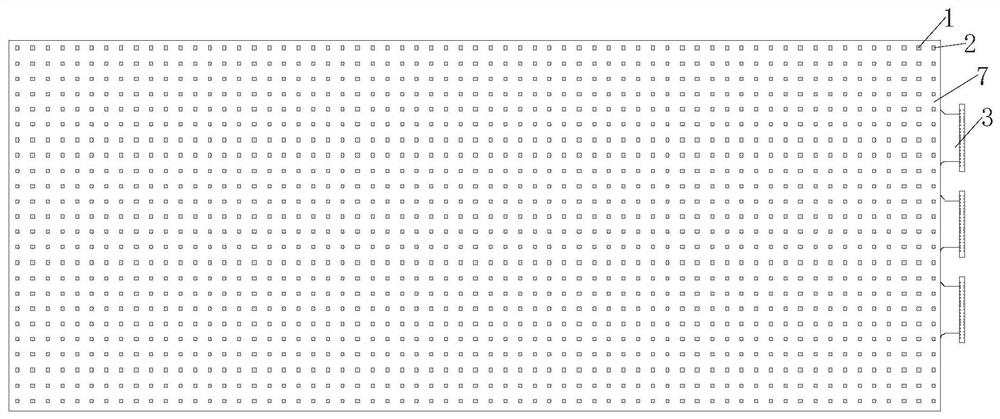

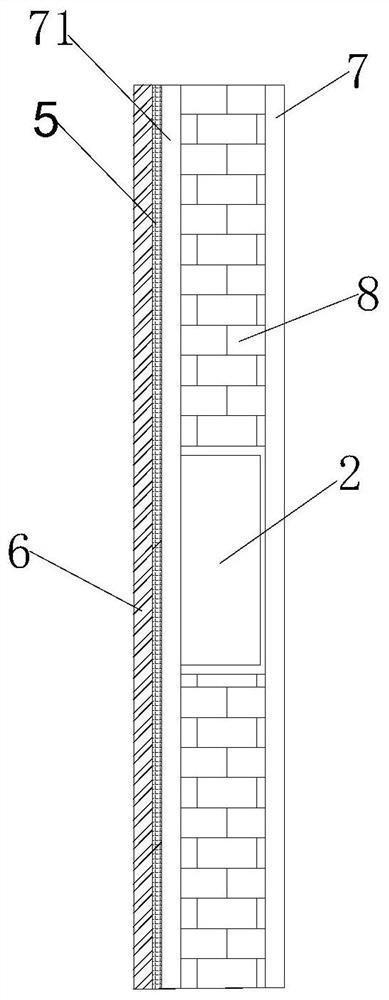

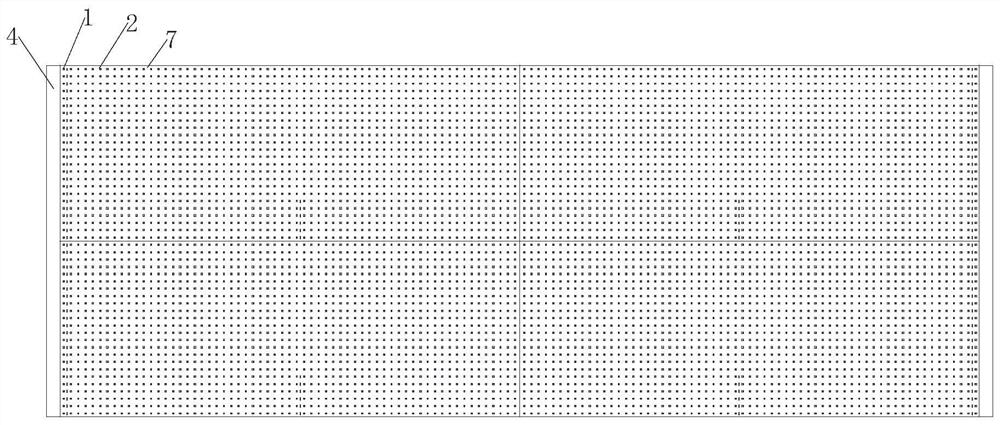

[0011] Such as Figures 1 to 3 The embodiment shown discloses a crystal film screen, which is formed by splicing multiple single crystal film screens, each single crystal film screen includes an LED light source module 2, and LED lights are uniformly arranged on the LED light source module 2 Bead 1, is electrically connected with LED light source module 2 and is arranged on the electric plug 3 of LED light source module 2 side ends; Also includes transparent substrate 6, is provided with transparent double film 5 on transparent substrate 6, transparent double film 5 surface The lower layer of transparent pressure-sensitive double-sided adhesive 71 is installed, the upper end of the lower layer of transparent pressure-sensitive double-sided adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com