Double-row blade battery OCV/ACIR testing device

A test device and blade technology, which is applied in the directions of measuring devices, measuring device casings, components of electrical measuring instruments, etc., to achieve the effect of simple structure, small space ratio, and solving test problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

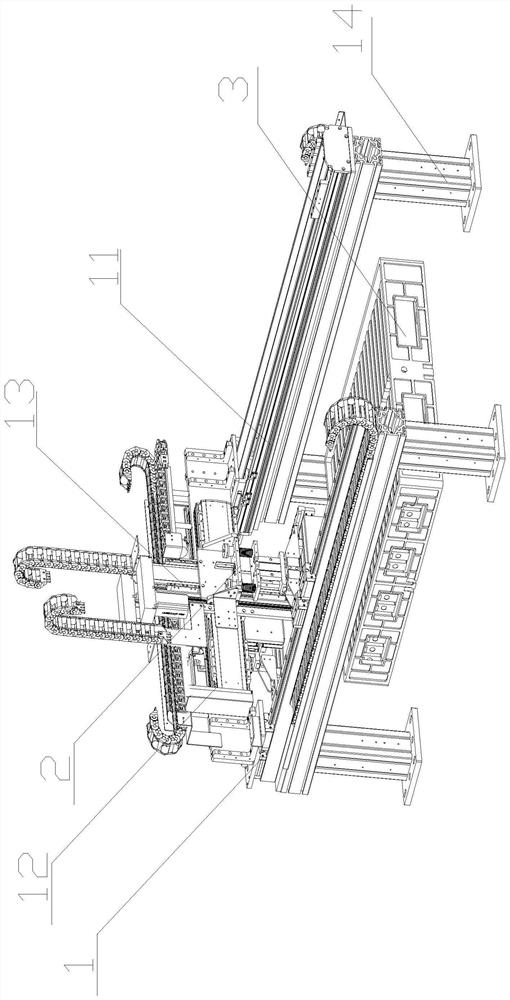

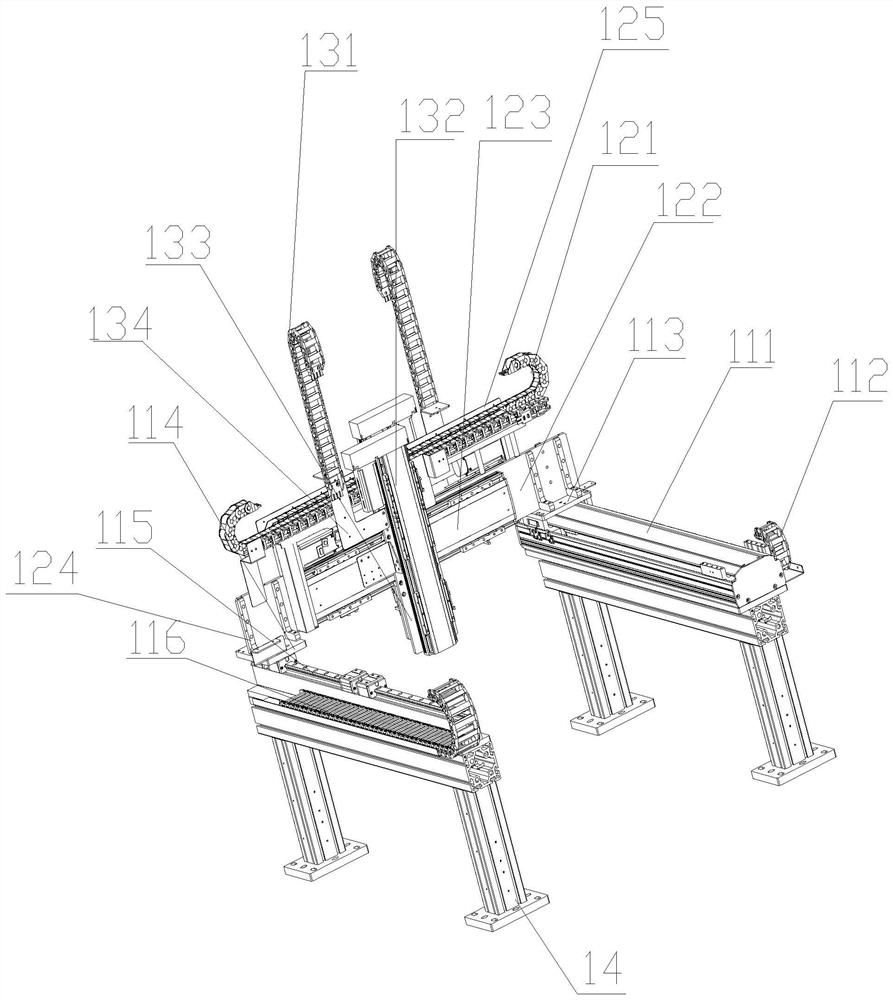

[0026] Embodiment 1 A dual-blade battery OCV / ACIR test device according to the present invention, including:

[0027] The three-axis mechanical module assembly 1 is used to drive the probe test assembly 2 to perform an X-axis, a y-axis, a Z-axis motion module, including the X-axis assembly 11, the Y-axis assembly 12, the Z-shaft assembly 13 and the module support assembly. 14; the axial direction of the X-axis assembly 11, the shaft assembly 12, and the z-shaft assembly 13 is defined as the X-axis direction, the y-axis direction, respectively, and the X-axis assembly 11 horizontal frame is mounted on the module support assembly. 14 of the top of the 14, the Y-axis assembly 12 is slidably arranged on the X-axis assembly 11 and maintains the Y-axis assembly 12 and the X-axis assembly 11 vertically; the Z-shaft assembly 13 is two Set, both the Y-axis assembly 12 is slidably mounted; the X-axis assembly 11, the Y-axis assembly 12, the Z-shaft assembly 13 can be moved to the probe te...

Embodiment 2

[0038] Example 2 Test Movement Description by using a two-row blade battery OCV / ACIR test device according to Embodiment 1:

[0039] 1) After the core tray 3 flows into the OCV / ACIR test device, the electrical core tray 3 is positioned to position, and the three-axis mechanical module assembly 1 operates, and the gas claw 222 is moved to the set position. The gas claw 222 closes the core 4 in the clamping of the cell tray 3, at which point the probe 232 is connected to the tap of the electrical core 4, start testing;

[0040] 2) After the test is completed, the gas claw 222 is released, the Z-axis module 13 rises and moves to the next test station until all the cells 4 test completed in the electrical core tray 3, three-axis mechanical modules The assembly 1 returns to the origin, the battery core tray 3 flows into the next step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com