Device and method for adjusting and replacing swing sensor of hydraulic turbine set on line

A sensor and unit technology, applied in the direction of machines/engines, hydropower, mechanical equipment, etc., can solve the problem that the online monitoring system of the unit cannot correctly reflect the swing data, and affects the operation and maintenance personnel on the operation status of the unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

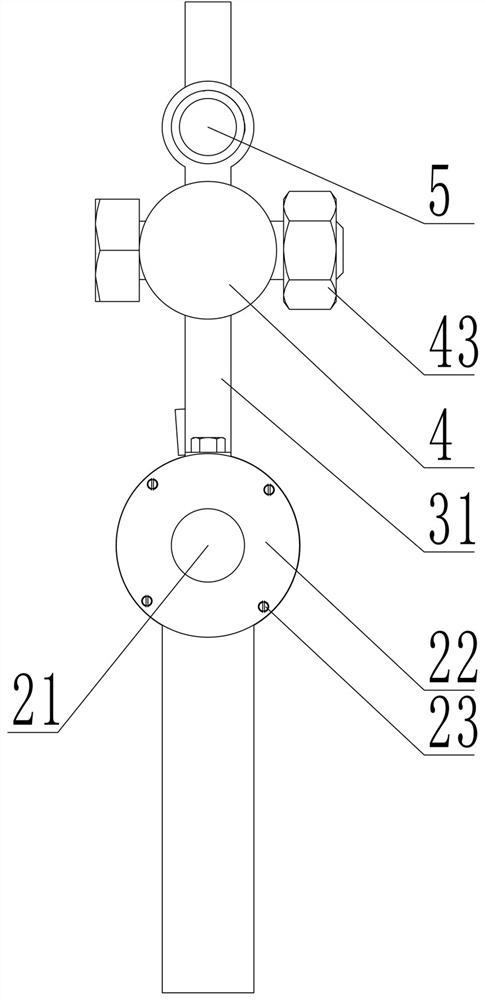

[0040] like Figure 1~Figure 7 Among them, a device for online adjustment and replacement of the swing sensor of a water turbine unit, which includes a fixed plate 1, an adjustment mechanism 2, a bracket 3, a mounting rod 4, and a swing sensor 5; the bushing 22 of the adjustment mechanism 2 is located on the fixed plate The two ends of the guide tube 11 of 1 cooperate with it, the guide rod 21 cooperates with the shaft sleeve 22, the bracket 3 cooperates with the guide rod 21 and is limited by the guide tube 11, the installation rod 4 is connected with the bracket 3 and the swing sensor 5; the guide rod 21 rotates and drives the bracket 3 drives the swing sensor 5 to move axially along the guide tube 11. The structure is simple, the adjustment mechanism 2 is connected with the fixed plate 1, the bracket 3 cooperates with the guide rod 21 of the adjustment mechanism 2, the installation rod 4 is connected with the bracket 3 and the swing sensor 5, the limit groove 12 and the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com