Combined staged fracturing device, asynchronous double-path extraction system and method

A segmented fracturing and conveying device technology, which is applied in the direction of mining fluid, earthwork drilling, drilling equipment, etc., can solve the problems of low gas drainage efficiency in soft and low-permeability coal seams, and achieve shortened operation cycle, shortened operation cycle, The effect of improving fracturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

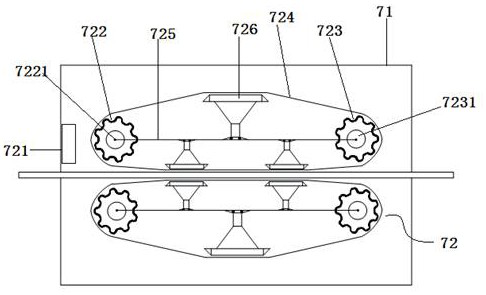

[0044] Compliance with the above technical solutions, such as Figures 2 to 4 , The present embodiment provides a downhole coiled tubing fracturing segment joint, downhole coiled tubing apparatus comprising a transport platform, the transport platform downhole coiled tubing apparatus 1 in the lateral front-to-rear lift cylinder with a vertically disposed sequentially 2, the power delivery device downhole coiled tubing BOP lift crane 3 and 4, the drum 2 is provided with a lift cylinder 5, with about a downhole coiled tubing 6 on the drum 5, the downhole coiled tubing is provided on the power transmission device 3 lifts continuous downhole tubing power transfer device 7, provided with a blowout preventer BOP lift 4 8;

[0045] BOP 8 and 9 is connected to the orifice means, the orifice device 9, 8 and the BOP power downhole coiled tubing annulus formed between the conveying device 7; 6 coiled tubing downhole in coiled tubing downhole in a power driven conveyor device 7 reciprocate bac...

Embodiment 2

[0058] like Figure 5 , The present embodiment provides a two-way asynchronous staged fracturing combined gas drainage system comprising a disclosed embodiment of the downhole coiled tubing joint Example staged fracturing apparatus further comprises a downhole fracturing fluid shunt device 21, downhole fracturing fluid shunt device 21 and the ground input terminal connected to the output of the coiled tubing 22, a first output terminal of a downhole fracturing fluid shunt device 21 is connected to the annulus of sand fracturing fluid conduit 13, 21 downhole fracturing fluid shunt device a second output terminal through the coiled tubing downhole hydraulic fluid injection conduit 23 in communication with the downhole coiled tubing 6. the coiled tubing downhole hydraulic fluid injection conduit is provided with a coiled tubing downhole fluid delivery control valve 26, annulus 13 sand fracturing fluid conduit 23 It is provided with an annulus of sand fracturing fluid delivery control ...

Embodiment 3

[0068] Pumping the present embodiment the target coal seam mining a seam of high gas coal, the coal seam consistent coefficient f is 0.3, the gas content of the coal seam 14 ~ 20m 3 / T, is a high gas outburst, a serious threat to the safety of coal.

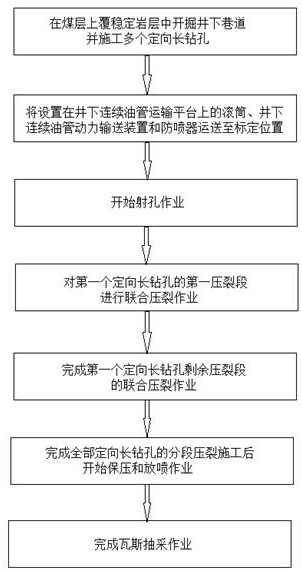

[0069] like figure 1 , The present embodiment provides a two-way asynchronous staged fracturing combined gas drainage method, the method disclosed in Example 2 Combined dual asynchronous staged fracturing implemented gas drainage system, comprising the steps of:

[0070] Step 1, in the coal seam, the coal seam is covered with a migration roadway and the construction of multiple orientation drilled holes, and then the next sleeve is completed;

[0071] In the present embodiment, as it is preferred, according to the distance between holes of the neighboring directional length of 50 ~ 60m long drilling arrangement, the design depth of hole 300 ~ 800m, divided into five segments fracturing, coiled tubing outer diameter surface is 82.6mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Gas content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com