Multifunctional rod

A multi-functional and unified technology, applied in the field of multi-functional rods, can solve the problems of consumables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

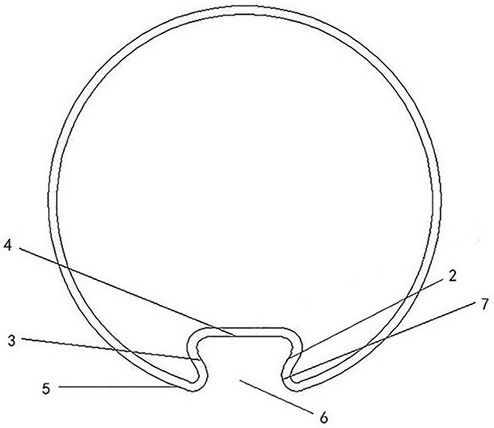

[0036] This embodiment provides a multifunctional pole 1, which is mainly used to improve the stability of the structure while saving materials. The multifunctional rod 1 includes: a first locking wall 2, a second locking wall 3, a connecting wall 4 and a supporting wall 5; the bottoms of the first locking wall 2 and the second locking wall 3 are connected by the connecting wall 4, And, the first locking wall 2 and the second locking wall 3 gradually approach outwards from the connecting wall 4 to form an installation opening 6 at their ends; the support wall 5 is arranged on both sides of the installation opening 6 and corresponds to the installation opening 6 There is a buffer angle 7 between the supporting wall 5 and the correspondingly connected locking wall.

[0037] In this example, if figure 2, the first locking wall 2 and the second locking wall 3 are folded towards the inside of the multi-functional rod 1 along one end of the connecting support wall 5, and are conne...

Embodiment 2

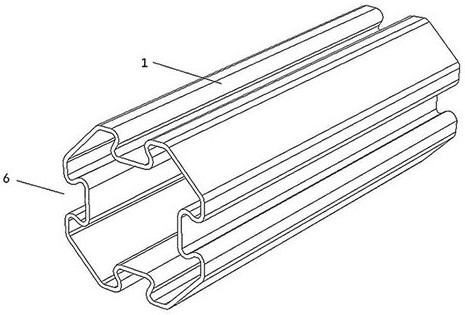

[0048] In this embodiment, different from the single installation port 6 in Embodiment 1, the multi-function bar 1 contains multiple installation ports. Due to the development of the 5G era, multiple devices need to be installed on the multi-function bar 1. The structure of a single installation port 6 is not enough to meet the needs of high-level installation of external equipment, so the number of installation ports 6 can be determined according to different environments, the number of installation devices, and the direction of installation devices. Secondly, if multiple external devices need to be installed, the multi-functional rod 1 with a single mounting port 6 can only be installed on the side of the multi-functional rod 1 containing the mounting port 6, which is likely to be affected by the pulling force of the external device at the mounting port 6. Multifunctional pole 1 for stabilization. In order to ensure the stability of the multi-function bar 1 when multiple ext...

Embodiment 3

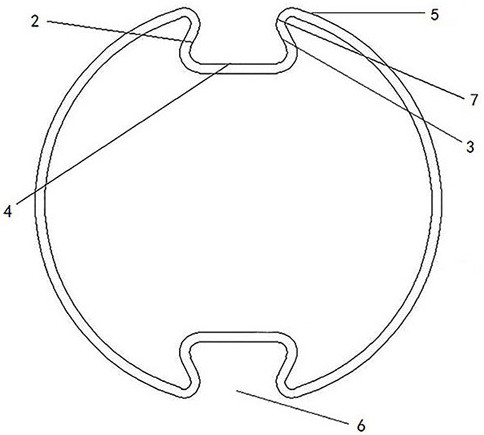

[0050] The difference between this embodiment and the first and second embodiments above is that, as Figure 6 , the support wall 5 includes a flat support portion 5-1, the flat support portion 5-1 is arranged close to the installation opening 6, and is connected with the locking wall on the corresponding side of the installation opening 6; the flat support of the support arms on both sides of the same installation opening 6 Section 5-1 is located in the same plane. On the one hand, one end of the flat supporting part 5-1 on both sides of the installation port 6 is connected to the corresponding locking wall to strengthen the locking wall, and the other end forms a certain angle with other parts of the supporting wall 5. The included angle is the same as the buffer angle in the first embodiment, and acts as a buffer to the force received by the flat support portion 5-1. On the other hand, the flat support portions 5-1 on both sides of the mounting opening 6 are in the same pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com