Large support grouting device and grouting method thereof

A bearing and large-scale technology, which is used in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of difficulty in ensuring the level of grouting, affecting the overall quality of the bearing construction, affecting the construction progress, etc., and meeting the requirements of low grouting environment. , The effect of simple structure and fast grouting construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

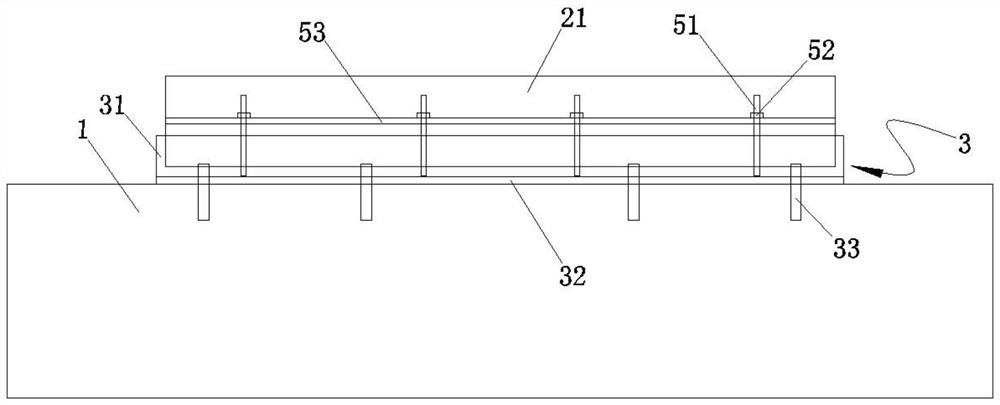

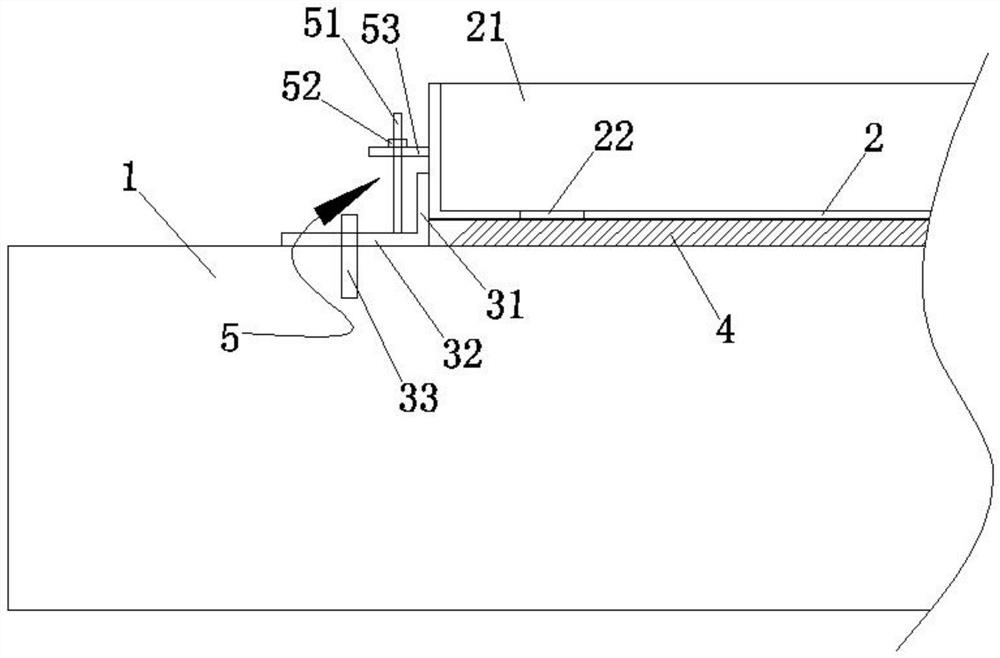

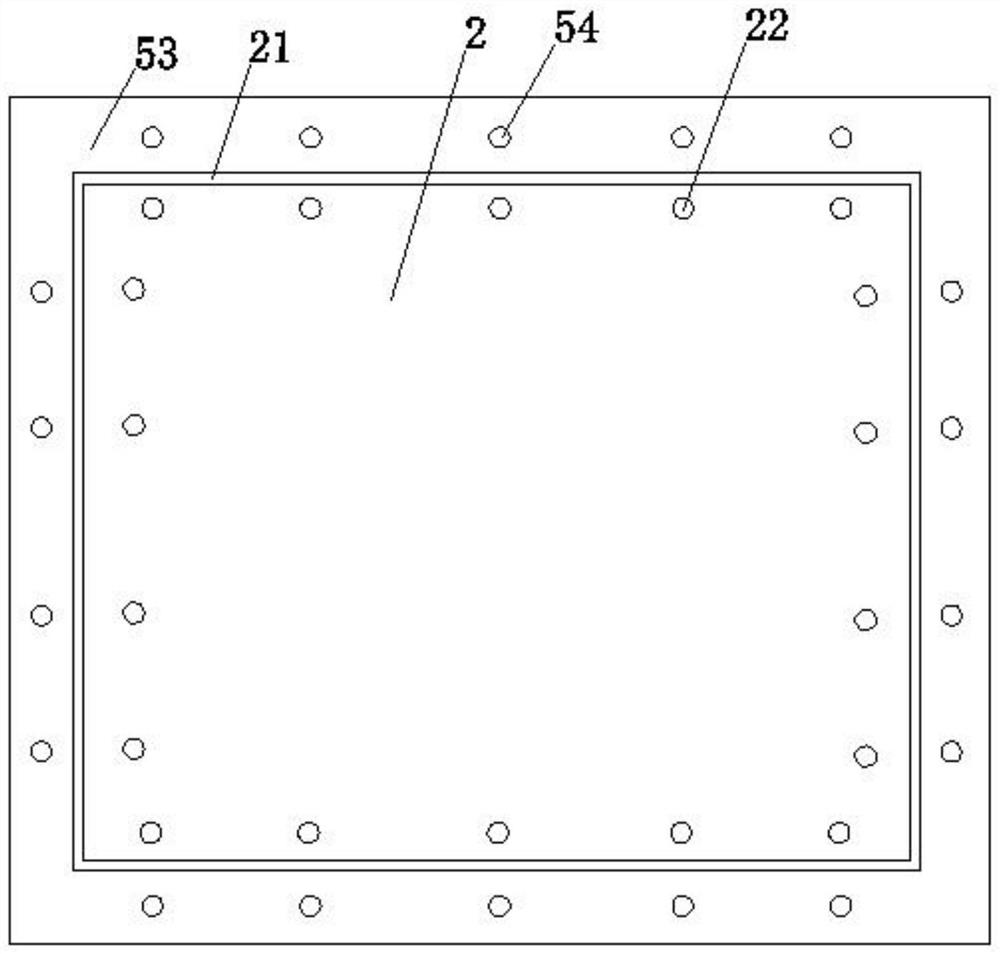

[0035] Such as Figure 1-7 As shown, a large-scale support grouting device provided in this example includes a side form 3 installed on the concrete cap 1 and used to accommodate the poured high-strength mortar 4, and is set in the side form 3 for the opposite side form 3 The inner high-strength mortar 4 compacts the horizontal grouting formwork 2 .

[0036] The invention has the advantages of simple structure, scientific and reasonable design, convenient use, low operation difficulty, low grouting cost, low requirements on the grouting environment during the grouting process, fast grouting construction speed, good effect, high grouting efficiency, dense and full grouting level, which can effectively guarantee Grouting quality and overall progress of support installation.

example 2

[0038] Such as Figure 1-7 As shown, a large-scale support grouting device provided in this example includes a side form 3 installed on the concrete cap 1 and used to accommodate the poured high-strength mortar 4, and is set in the side form 3 for the opposite side form 3 The inner high-strength mortar 4 compacts the horizontal grouting formwork 2 . The side formwork 3 includes a square-shaped side formwork body 31, and side formwork installation plates 32 distributed around the bottom periphery of the side formwork body 31;

[0039] In this example, on the basis of Example 1, the specific structure of the side formwork 3 is optimized. The side formwork 3 includes a side formwork plate body 31 in the shape of a mouth, and a side formwork installation plate 32 distributed around the outer periphery of the bottom of the side formwork plate body 31. ; The side formwork mounting plate 32 is fixed on the concrete platform 1 through expansion bolts 33 . In this way, the side formw...

example 3

[0041] Such as Figure 1-7 As shown, a large-scale support grouting device provided in this example includes a side form 3 installed on the concrete cap 1 and used to accommodate the poured high-strength mortar 4 , and is set in the side form 3 for the opposite side form 3 The inner high-strength mortar 4 compacts the horizontal grouting formwork 2 . The side formwork 3 includes a square-shaped side formwork body 31, and side formwork installation plates 32 distributed around the bottom periphery of the side formwork body 31; The side formwork body 31 is distributed vertically, and the side formwork mounting plate 32 is distributed vertically to the side formwork body 31 .

[0042]On the basis of Example 2, this example optimizes the specific structure of the side formwork plate body 31 and the side formwork mounting plate 32, the side formwork plate body 31 is vertically distributed, and the side formwork mounting plate 32 is distributed vertically to the side formwork plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com