Cloth folding and guiding device of sewing machine

A fabric folding and guiding device technology, which is applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of off-line or wrinkling of the sewing part, unstable sewing results, etc., and achieve the effect of a simple supporting structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

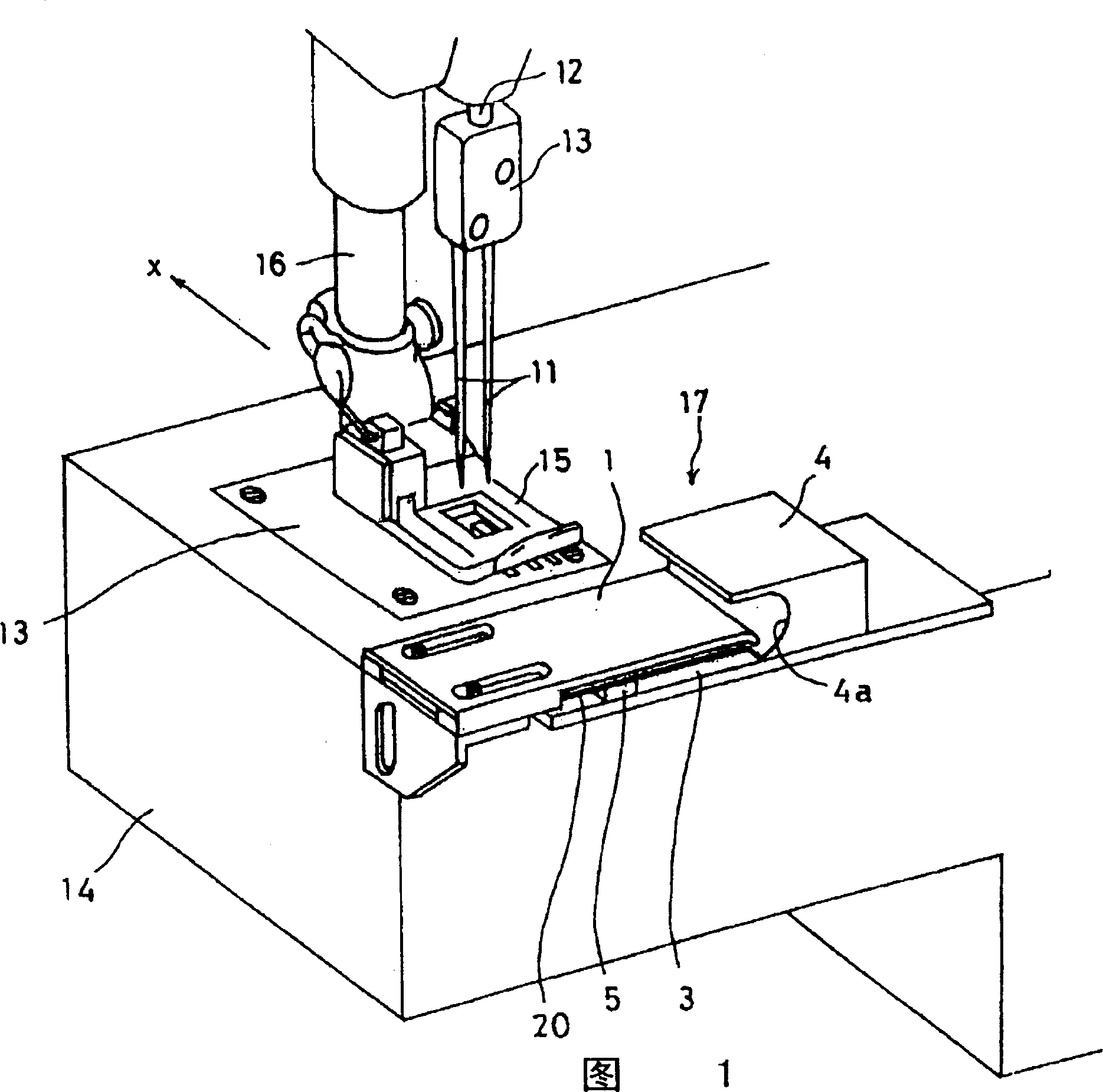

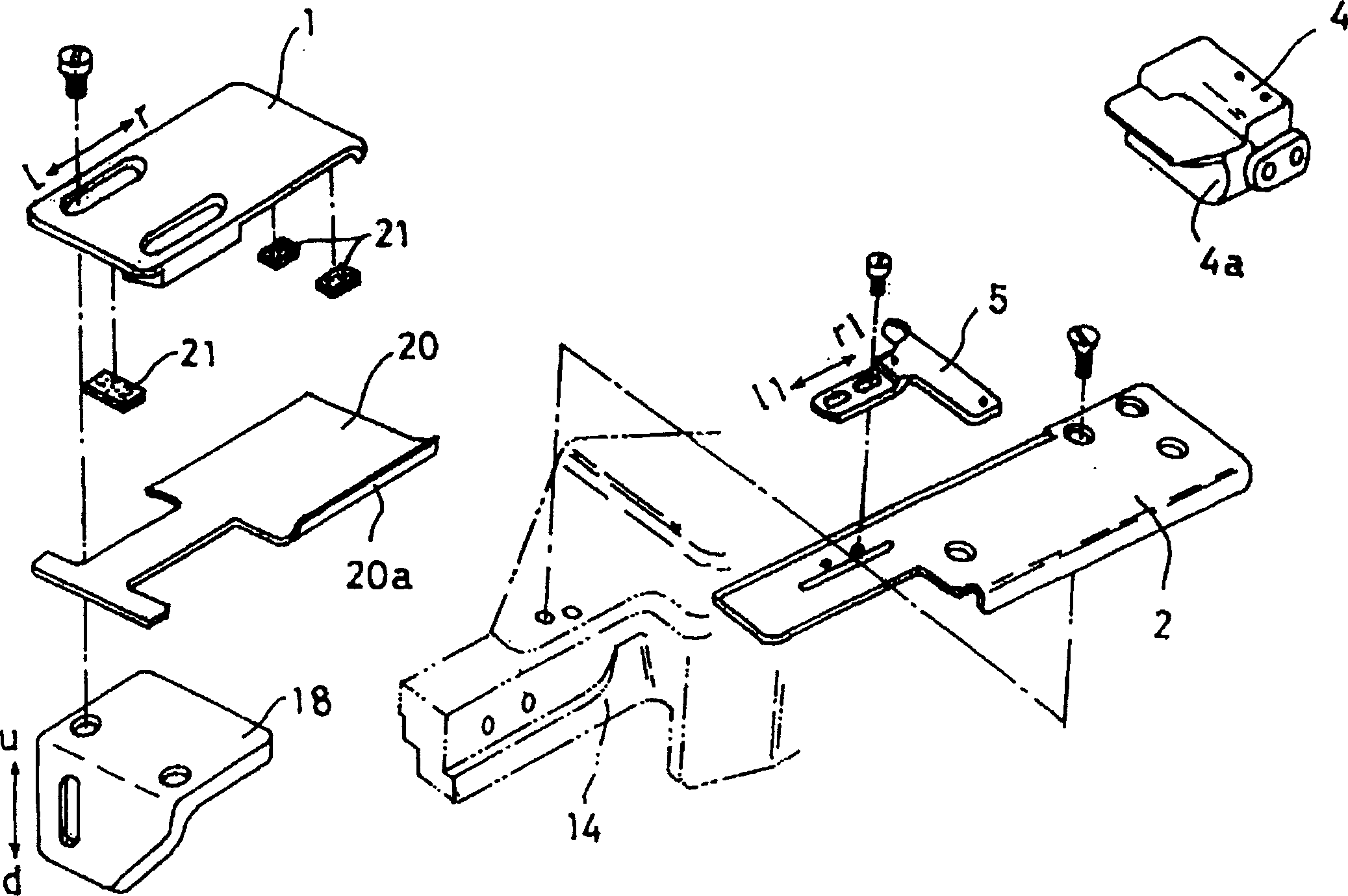

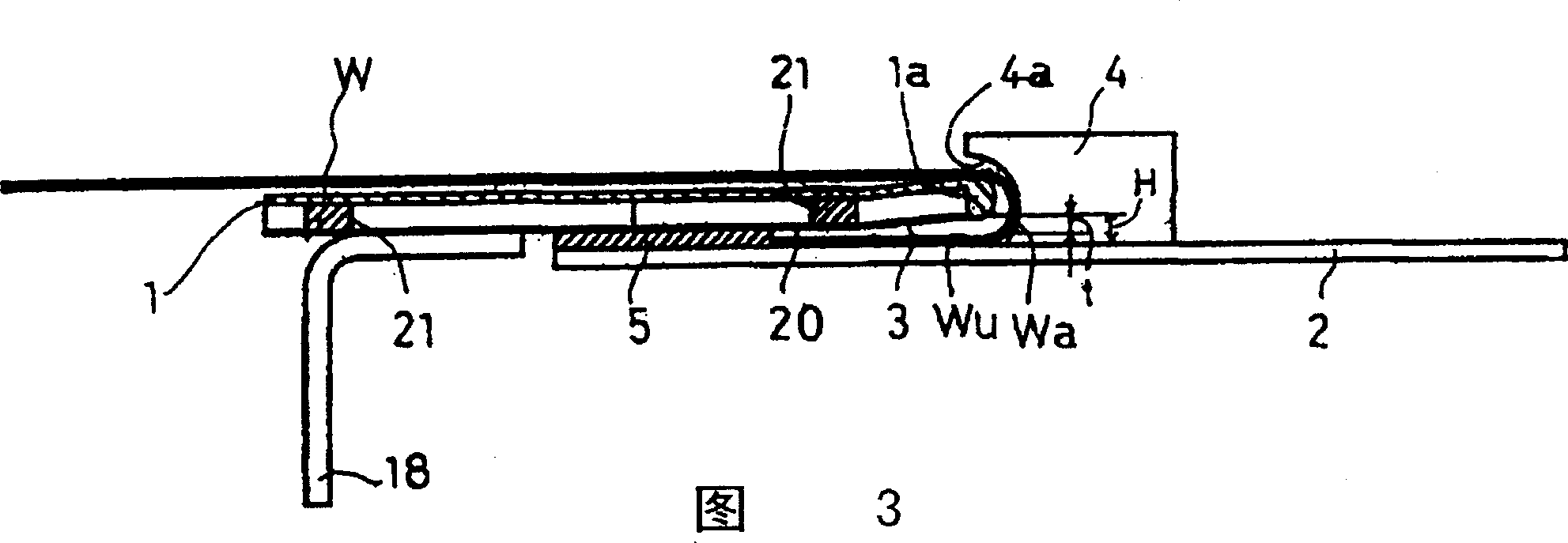

[0019] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0020] Fig. 1 is a schematic perspective view showing main parts of a cloth folding guide device of a sewing machine according to the present invention, figure 2 It is an exploded perspective view of the main part. In Figure 1 and figure 2 Among them, 11 is the needle installed on the lower end of the needle bar 12 through the needle clamp 13, and the needle bar 12 is supported on the front end of the sewing machine arm (not shown) in a reciprocating up and down manner. At the same time, the needle plate 13 with the needle drop portion falling into the penetrating state is fixed on the sewing machine table 14 in a horizontal posture. Parts (because it is a known technology, detailed description and illustrations are omitted). Reference numeral 15 denotes a pressing plate mounted on the lower end of the pressing rod 16, and the pressing rod 16 is supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com