PTFE filter bag cutting device for glass kiln and machining method thereof

A PTFE and glass kiln technology, applied in metal processing, packaging, bag making, etc., can solve the problems of affecting cutting operation, irregular cutting, poor stability, etc., achieve high efficiency in cutting process, increase tidy effect, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

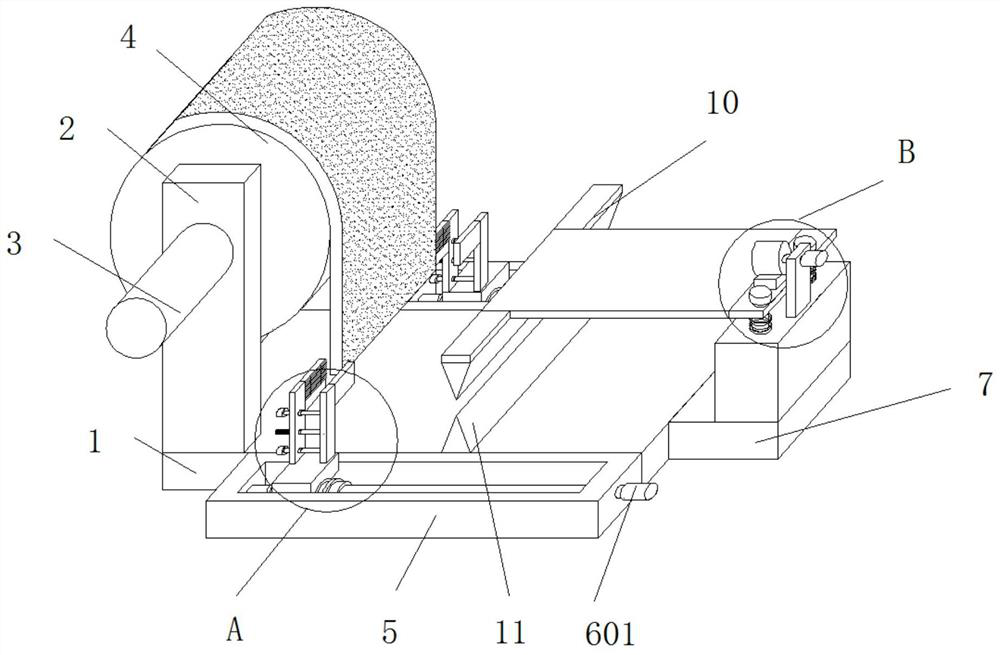

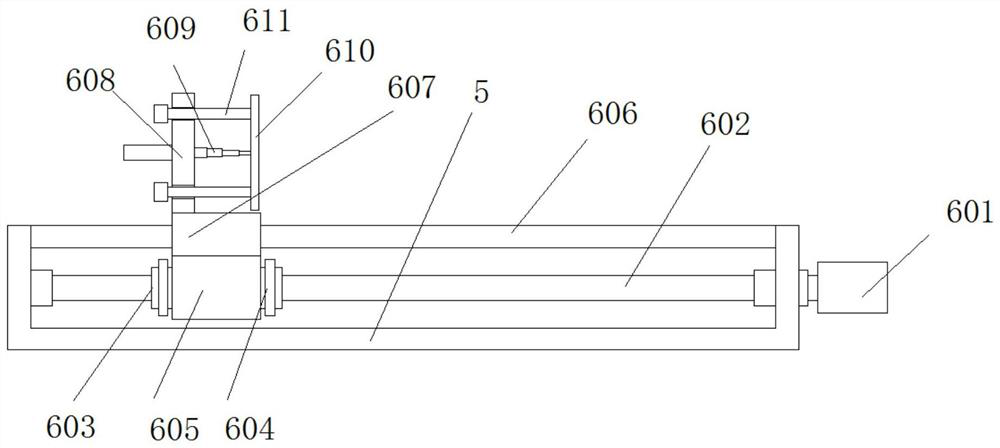

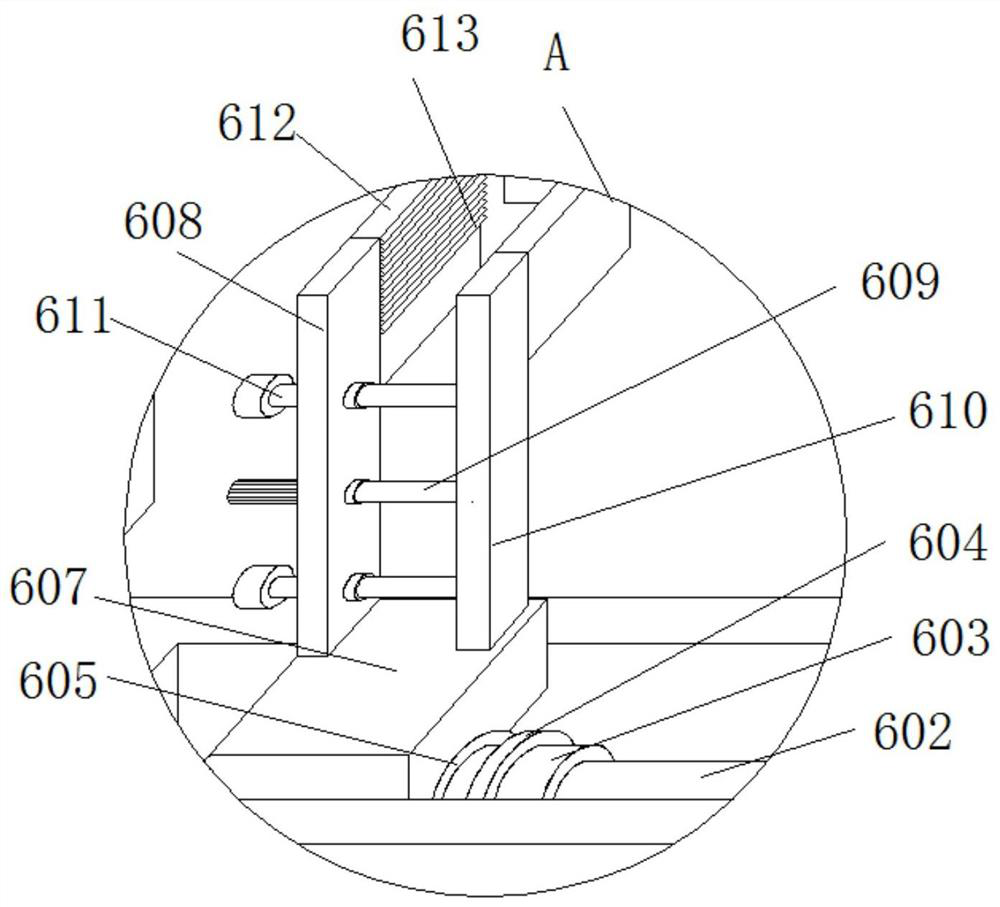

[0030] Such as Figure 1-5 As shown, a PTFE filter bag cutting device for glass kilns includes a base 1, a material wheel 4, a clamping mechanism and a cutting mechanism. The wheel 4 is installed between the front and rear first side plates 2, the front end of the material wheel 4 runs through the first side plate 2 and is connected to the first motor 3, the front and rear outer walls on the right side of the base 1 are equipped with a second side plate 5, and the second side plate 5 The inside is equipped with a clamping mechanism that can be adjusted according to the size of the raw material. The second connecting plate 7 is installed on the outer wall on the right side of the base 1. The upper end of the second connecting plate 7 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com