Adjusting tool of wind power tower cylinder edge rolling hydraulic machine

A technology for wind power towers and hydraulic presses, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to roll round hydraulic press support, inability to roll tower sections, and poor support stability, etc. The effect of operation stability, expansion of position adjustment range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

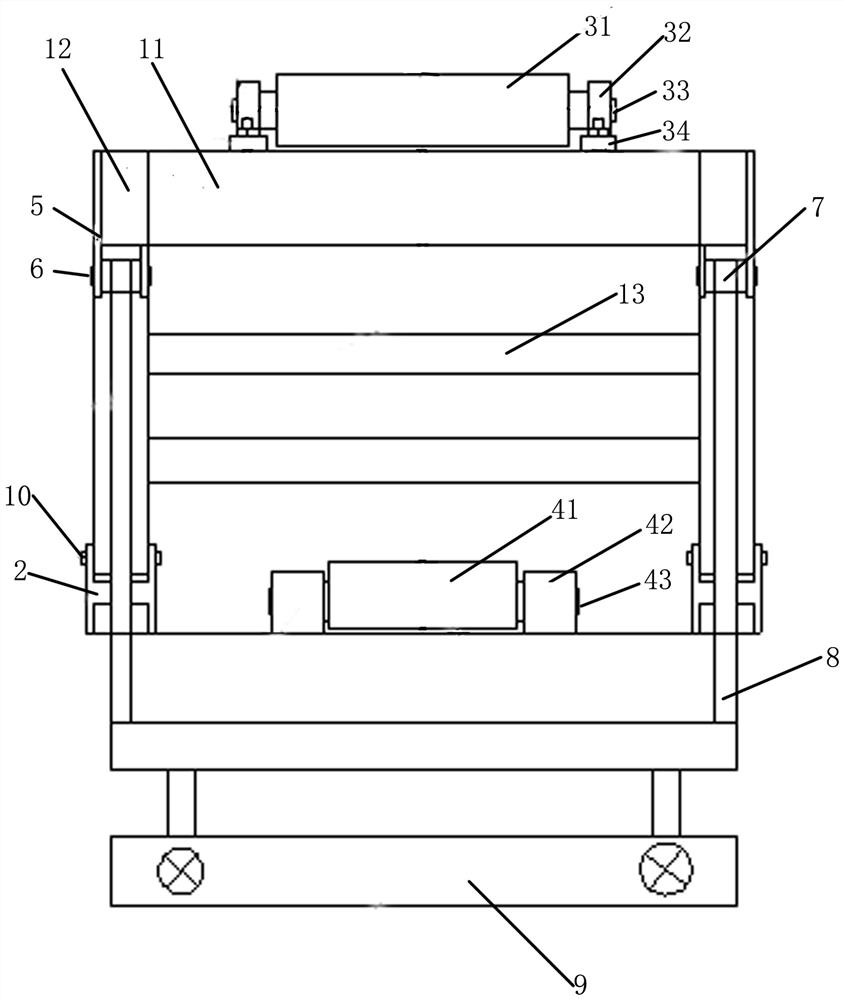

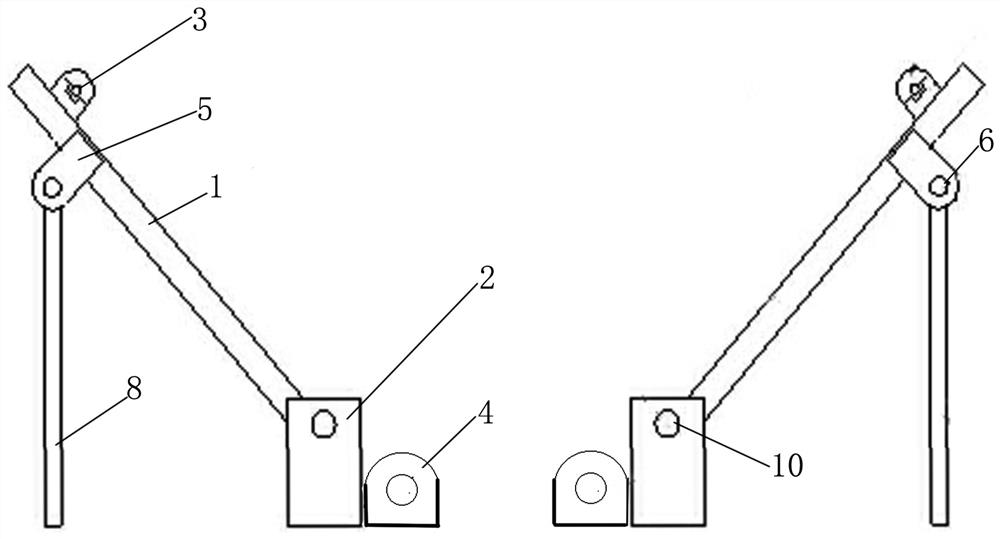

[0019] Please refer to figure 1 and figure 2 , which shows a wind power tower rolling hydraulic machine adjustment tool, including two symmetrically arranged connecting square tube assemblies 1; square tube 11, two oblique square tubes 12, and two reinforced square tubes 13, the tops of the two oblique square tubes 12 are respectively welded to the two ends of the horizontal square tube 11, and the two reinforced square tubes 13 are formed from From top to bottom, it is welded horizontally between the inner walls of two oblique square tubes 12; the left and right sides of the upper end of each oblique square tube 12 are welded with support baffles 5 inclined to the outside and downward respectively, and the support baffles 5 at the inner end They are all located at the lower adjacent position of the horizontal square tube 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com