Paint spraying and drying equipment

A technology for drying equipment and coatings, applied in the coating, spray booth, spray device and other directions, can solve the problems of uneven drying of coatings and lack of coating stirring function, and achieve complete drying effect, high stirring efficiency, and improved smoothness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

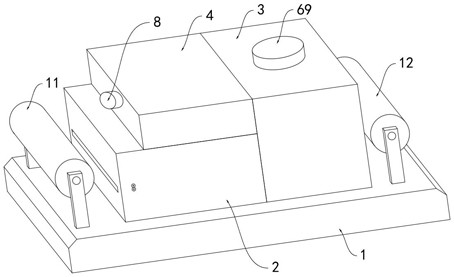

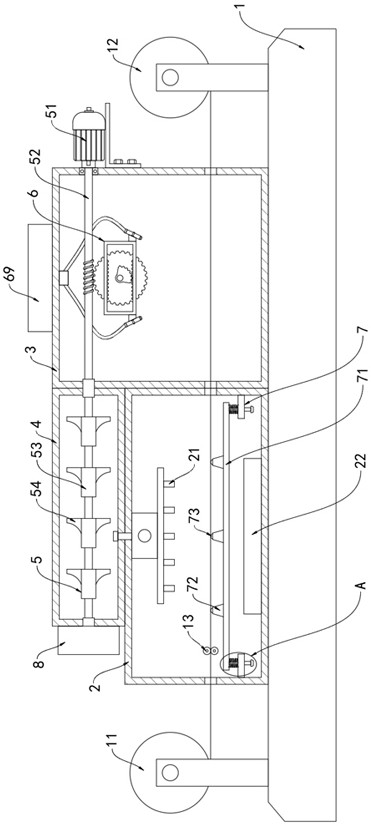

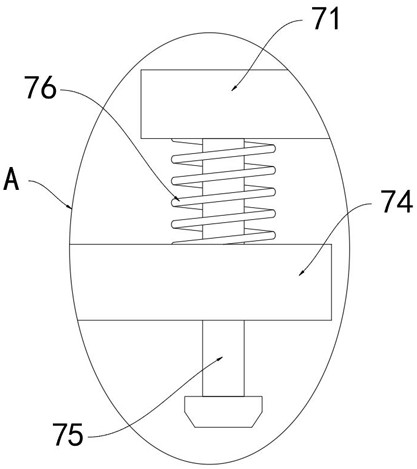

[0032] like Figure 1-3 As shown, a paint spraying and drying equipment includes a machine platform 1, an atomized spray box 2 and an air drying box 3, and the atomized spray box 2 and the air drying box 3 are fixed side by side on the machine platform 1, and the atomized spray box The top of the box 2 is provided with a paint box 4, the paint box 4 is provided with a stirring mechanism 5 for stirring and mixing the paint, and the air drying box 3 is provided with a drying mechanism 6 for heating and drying the paint;

[0033] Specifically, the stirring mechanism 5 includes a driving motor 51, the output end of the driving motor 51 is connected with a rotating shaft 52 through a coupling, and the rotating shaft 52 extends horizontally into the paint tank 4, and several rotating cylinders 53 are arranged horizontally and equidistantly in the paint tank 4 , and the rotating cylinder 53 is coaxially fixed on the rotating shaft 52. One end of the rotating cylinder 53 is open, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com