Manufacturing method of color masking veneer in oral crown

A manufacturing method and veneer technology, applied in the directions of additive manufacturing, manufacturing tools, dental prostheses, etc., can solve the problem of high permeability limiting the scope of glass ceramics, reduce technical sensitivity, improve strength and treatment efficiency, and expand clinical Effects of Aesthetic Treatment Areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will be described in detail in conjunction with specific examples, but the protection scope of the present invention is not limited by the specific examples.

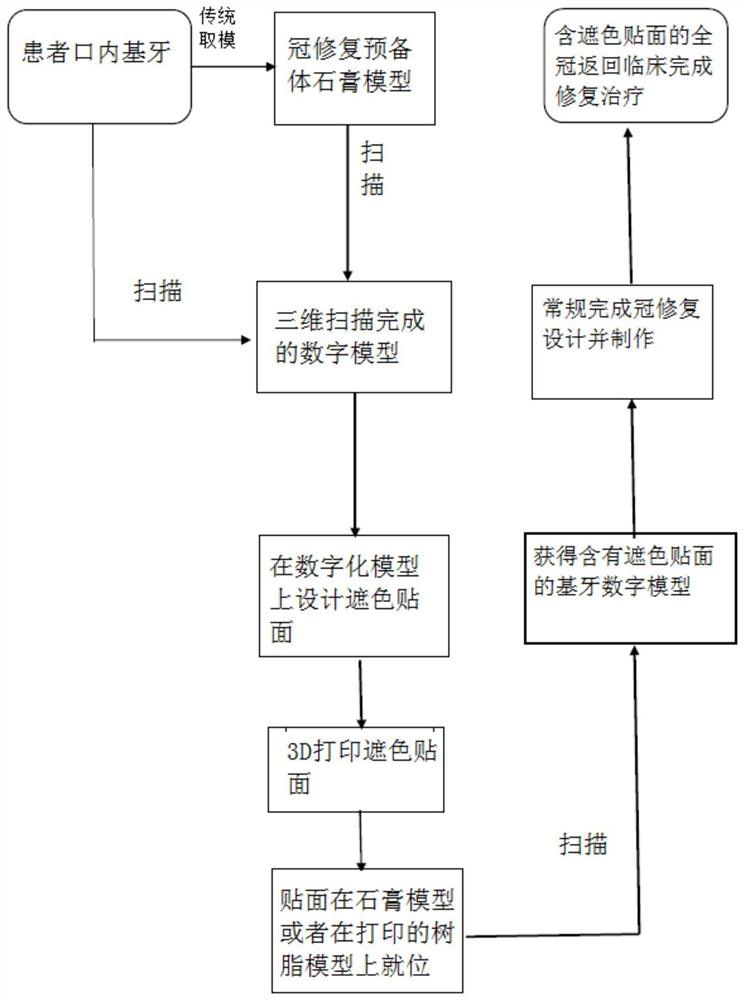

[0028] Such as figure 1 As shown, the present invention provides a method for making an internal color-blocking veneer for oral restoration full crown, the steps are as follows:

[0029] S1. Obtain the digital 3D model of the crown preparation from the abutment preparation with the shoulder trimmed through the oral scanner; it is also possible to prepare a plaster model of the crown preparation by traditional impression taking, and then use the scanning equipment to prepare the plaster of the crown restoration Transform the solid model into a digital three-dimensional model;

[0030] S2. After importing the digital model into the oral computer-aided design (CAD) software to select the veneer restoration, draw the position of the veneer termination line on the labial side of the abutment teeth;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com