Bean curd pressing equipment

An equipment and tofu technology, applied in the field of food processing, can solve problems such as laborious and time-consuming, and achieve the effect of improving the effect, good use reliability, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

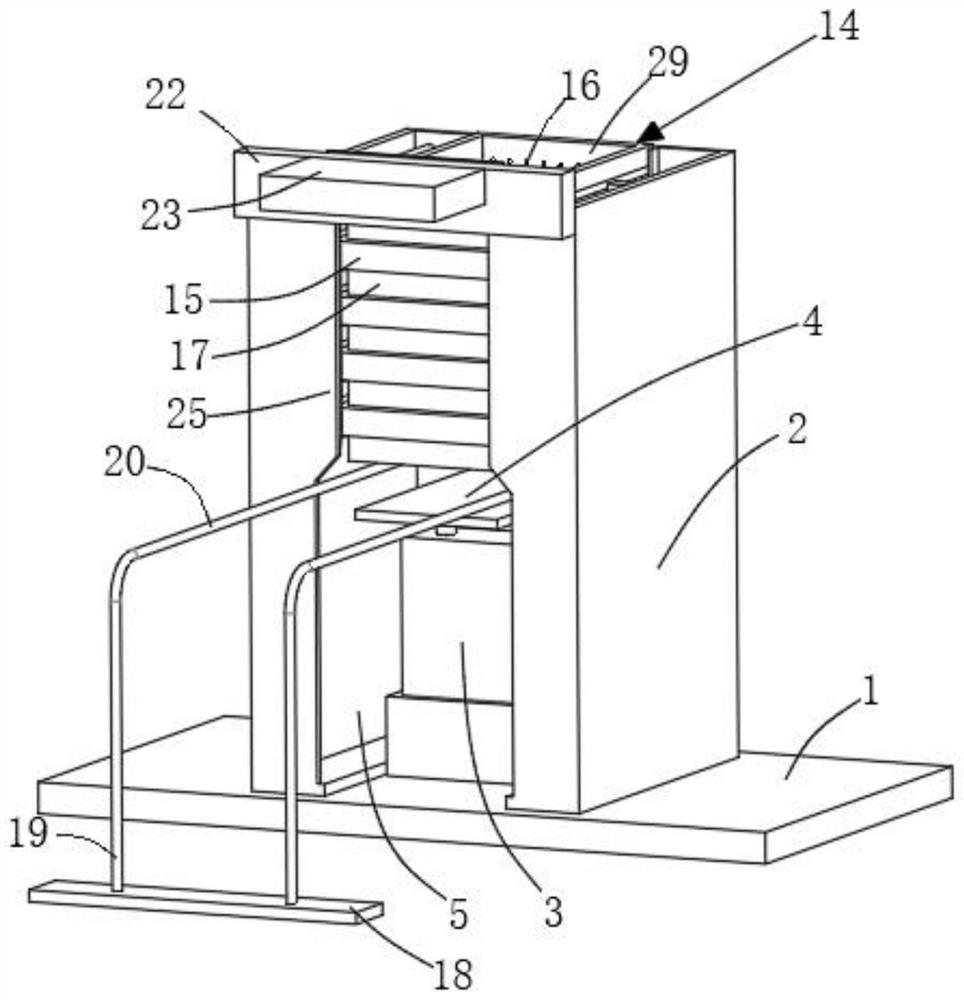

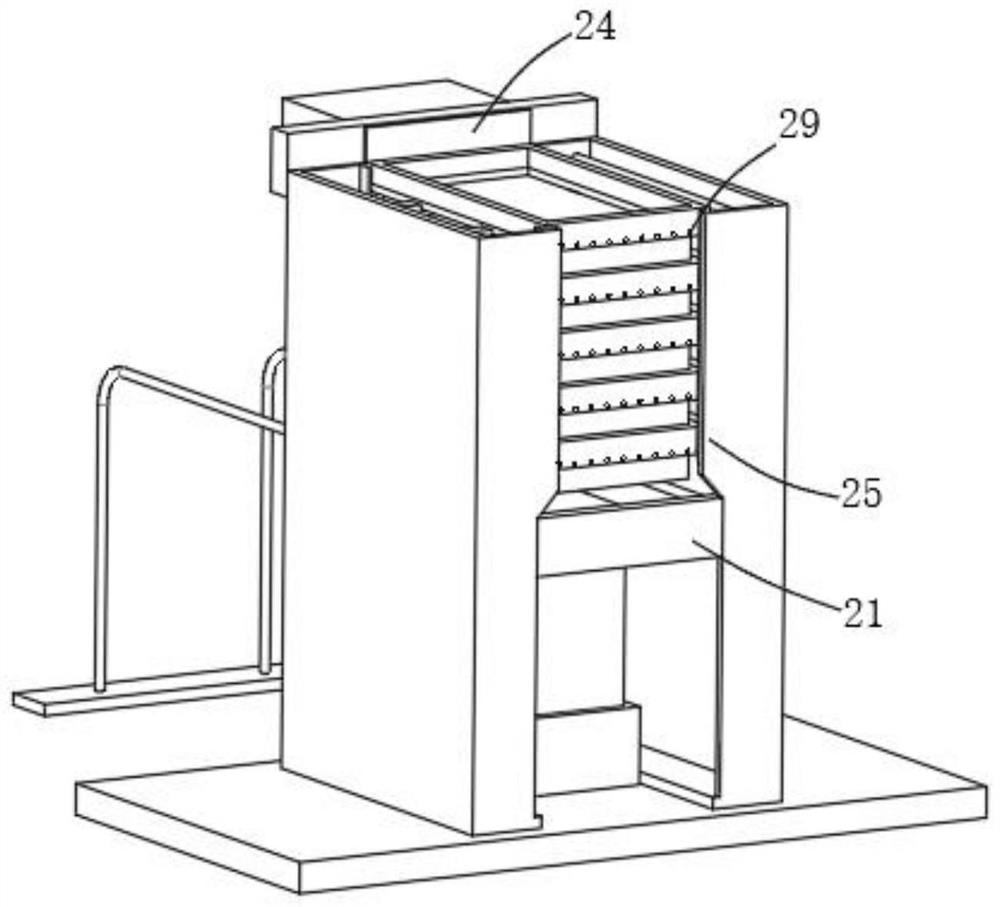

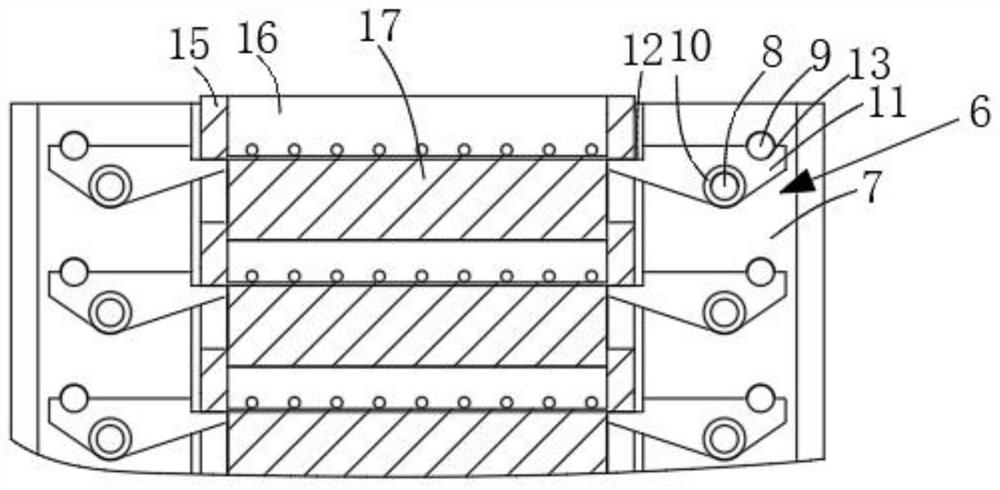

[0024] Embodiment: a kind of tofu pressing equipment, as attached figure 1 And attached figure 2 As shown, the first base plate 1 is included, and the first base plate 1 is provided with symmetrically arranged mounting blocks 2, and a lifting cylinder 3 is arranged between the mounting blocks 2, and a lifting plate 4 is provided at the output end of the lifting cylinder 3; the mounting block 2 are all provided with the mounting groove 5 towards lifting cylinder 3, attached image 3As shown, five installation rod groups 6 are arranged in the installation groove 5 above the lifting plate 4, and there are placement gaps 7 between adjacent installation rod groups 6. The mounting rod 8 between the groove surfaces, the mounting rod 8 is provided with a limit rod 9 parallel to it on the side away from the lifting cylinder 3, and the mounting rod 8 is provided with a rotating member 10 that is symmetrically arranged and connected to it in rotation. A support block 11 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com