Rotary excavating cutting pick with long service life

A technology with long life and cutting teeth, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of short service life, high cost consumption, lack of durability, etc., to increase wear resistance, prolong service life, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

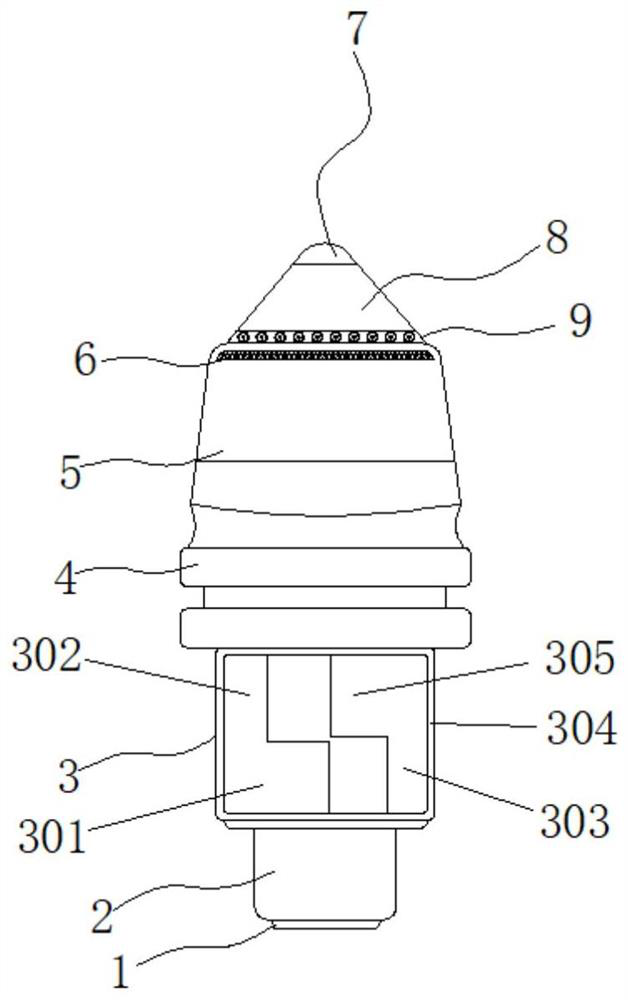

[0021] Example 1: See Figure 1-4 , a rotary digging pick with long service life, comprising a tooth shank 2, the bottom end of the tooth shank 2 is provided with a connection port 1, the top of the tooth shank 2 is provided with a limit structure 3, and the top of the tooth shank 2 is fixedly connected with a bearing 4 , a protective structure 9 is provided above the tooth handle 2, and a durable structure is provided above the tooth handle 2;

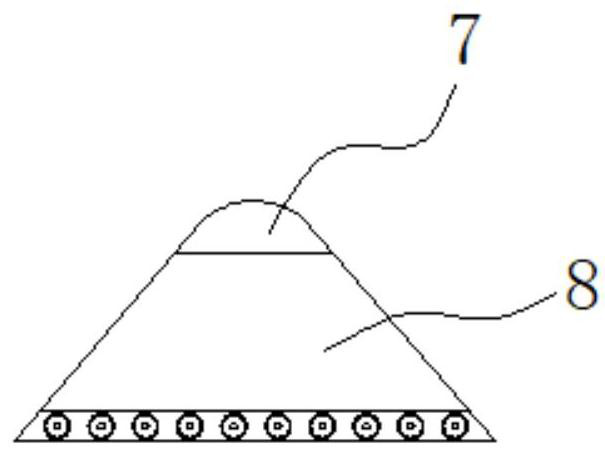

[0022] see Figure 1-4 , a rotary digging pick with long service life also includes a durable structure, the durable structure includes a head body 5, the head body 5 is fixedly connected above the bearing 4, the top of the head body 5 is provided with a diamond layer 6, and the head body 5 The top is fixedly connected with a conical shell 8, and the top of the conical shell 8 is fixedly connected with a tooth head 7;

[0023] The tooth head 7 is arc-shaped, and the diamond layer 6 is provided with multiple layers of diamonds stagge...

Embodiment 2

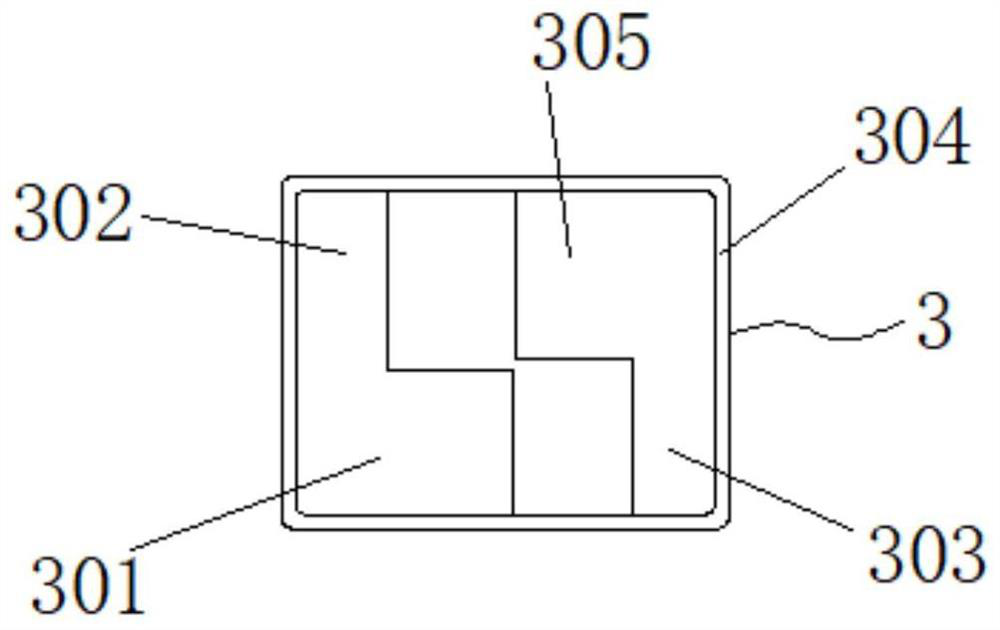

[0025] Embodiment 2: The limiting structure 3 is composed of a first limiting block 301 , a first locking slot 302 , a second locking slot 303 , a tooth body 304 and a second limiting block 305 , and the tooth body 304 is arranged on the top of the tooth handle 2 One side inside the tooth body 304 is provided with a first limiting block 301, the top end of the first limiting block 301 is provided with a first card slot 302, and the other side inside the tooth body 304 is provided with a second limiting block 305, The bottom end of the second limiting block 305 is provided with a second card slot 303;

[0026] The first limiting block 301 is engaged with the second slot 303, and the second limiting block 305 is engaged with the second slot 303 to increase the impact speed;

[0027] Specifically, such as figure 1 with image 3 As shown, by setting the first stopper 301, the first slot 302, the second slot 303 and the second stopper 305, the tooth head 7 impacts the formation d...

Embodiment 3

[0028] Embodiment 3: The protective structure 9 is composed of a positioning hole 901, a protective sleeve 902, a drill bit 903 and a circular seat 904, the circular seat 904 is fixedly connected to the top of the head body 5, and the top of the circular seat 904 is provided with multiple sets of positioning holes 901, a protective cover 902 is provided above the positioning hole 901, and a drill bit 903 is provided inside the positioning hole 901;

[0029] Drill bits 903 are arranged at equal intervals on the outside of circular seat 904 to improve work efficiency and shorten work time; specifically, as figure 1 with Figure 4 As shown, by being provided with a positioning hole 901, a protective sleeve 902, a drill bit 903 and a circular seat 904, the drill bit 903 is placed inside the positioning hole 901 during use, and a circle of protective sleeve 902 is arranged outside the drill bit 903 to protect the drill bit 903. , reduce the friction of the drill bit 903, realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com