Deceleration strip suitable for snowy days

A speed bump and snow-weather technology, applied in the field of road facilities, can solve problems such as prone to safety accidents and difficult to find speed bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

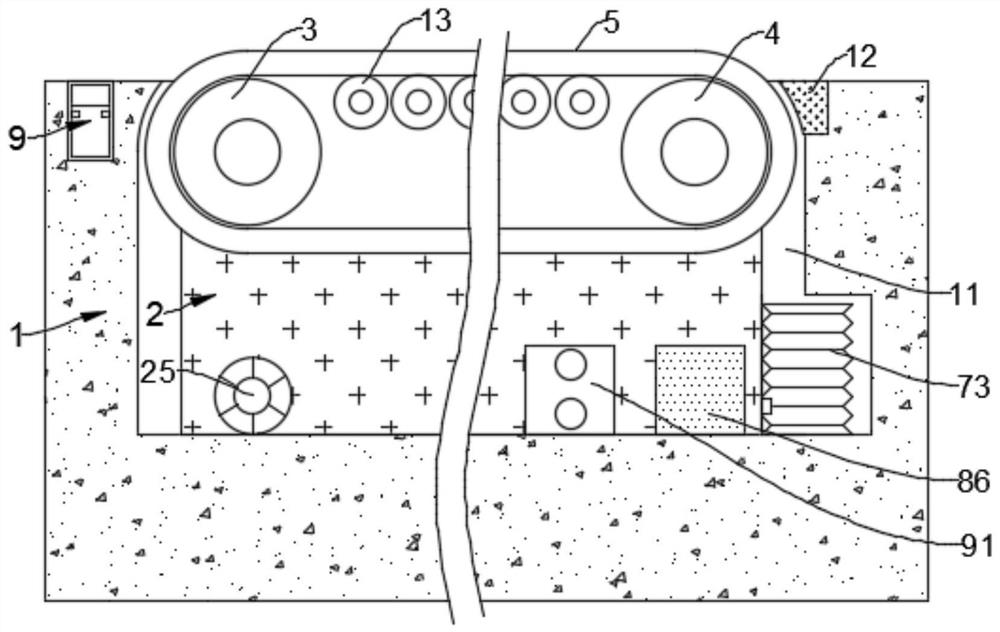

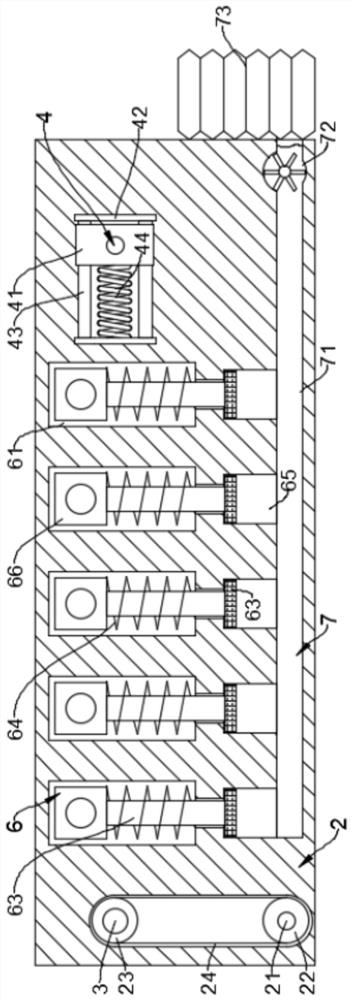

[0026] Such as Figure 1-5 As shown, a deceleration belt suitable for snowy weather includes a deceleration groove 11 arranged on the ground 1, two fixed plates 2 are fixedly connected to the inner wall of the deceleration groove 11, and a driving wheel is rotatably connected between the two fixed plates 2 3 and the driven wheel 4, a reduction belt 5 is arranged between the driving wheel 3 and the driven wheel 4, and a support roller 13 supported by a plurality of reduction belts 5 is rotatably connected between the two fixed plates 2 .

[0027] The driving pulley 3, the driven pulley 4 and the support roller 13 are all spherical structures, and the speed reduction belt 5 is a belt-shaped structure that fits the drive pulley 3, the driven pulley 4 and the support roller 13, and the side section is arc-shaped.

[0028] Because special deceleration belt 5 and support roller 13 will play the function of deceleration belt.

[0029] One of the fixed plates 2 is rotatably connected...

Embodiment 2

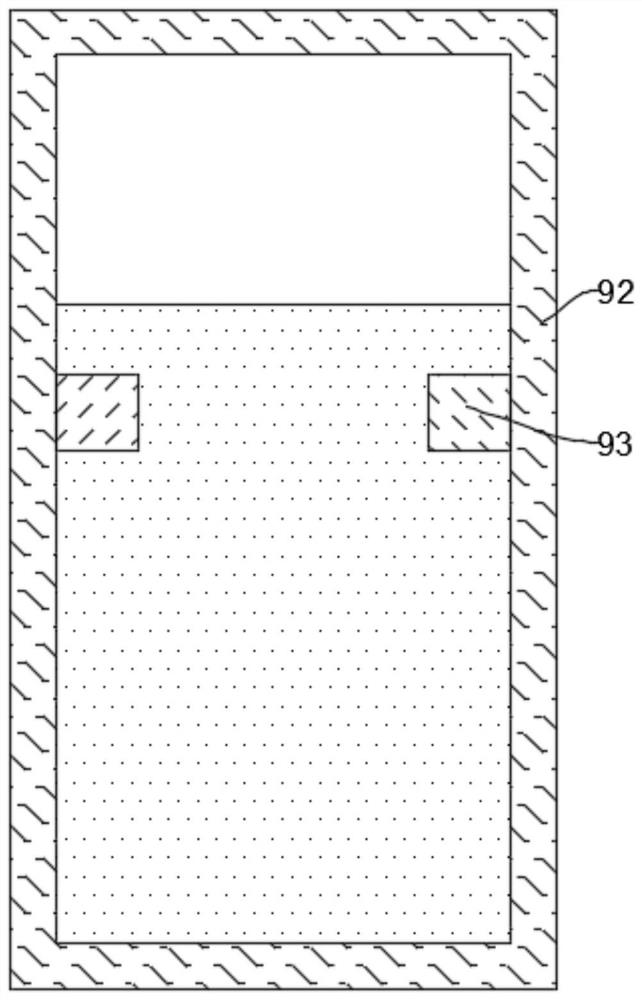

[0049] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 lies in that: a detection board 14 is fixedly connected to the ground 1 , the detection board 14 is made of piezoresistive material, and the detection board 14 is electrically connected to the motor 25 .

[0050] When the vehicle passes the detection plate 14, the detection plate 14 will stop the motor 25 at this time, thereby avoiding that when the vehicle passes the deceleration belt 5, the deceleration belt 5 still moves laterally and causes a safety accident.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com