Zipper pull of sportswear zipper

A technology for sportswear and zippers, applied in clothing, sliding fastener components, applications, etc., can solve problems such as poor quality of pull tabs, achieve the effect of increasing the sinking feeling, stabilizing the connection structure, and improving texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

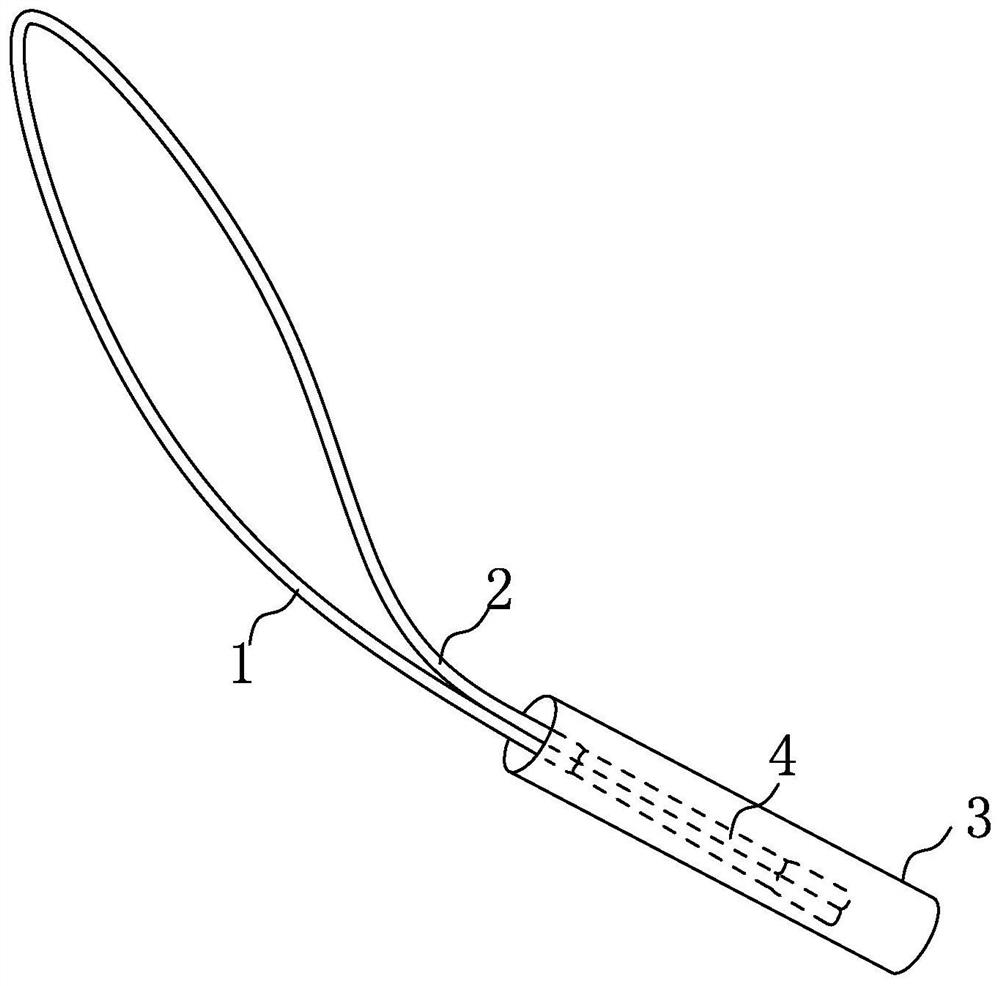

[0036] refer to figure 1 and figure 2 , a pull tab for a sportswear zipper, comprising a drawstring with a first rope end 1 and a second rope end 2, the first rope end 1 or the second rope end 2 passing through the slider to be connected with the slider (the specific structure of slider is not shown in the figure);

[0037] A rope end fixing part 3 made of resin for fixing the first rope end 1 and the second rope end 2;

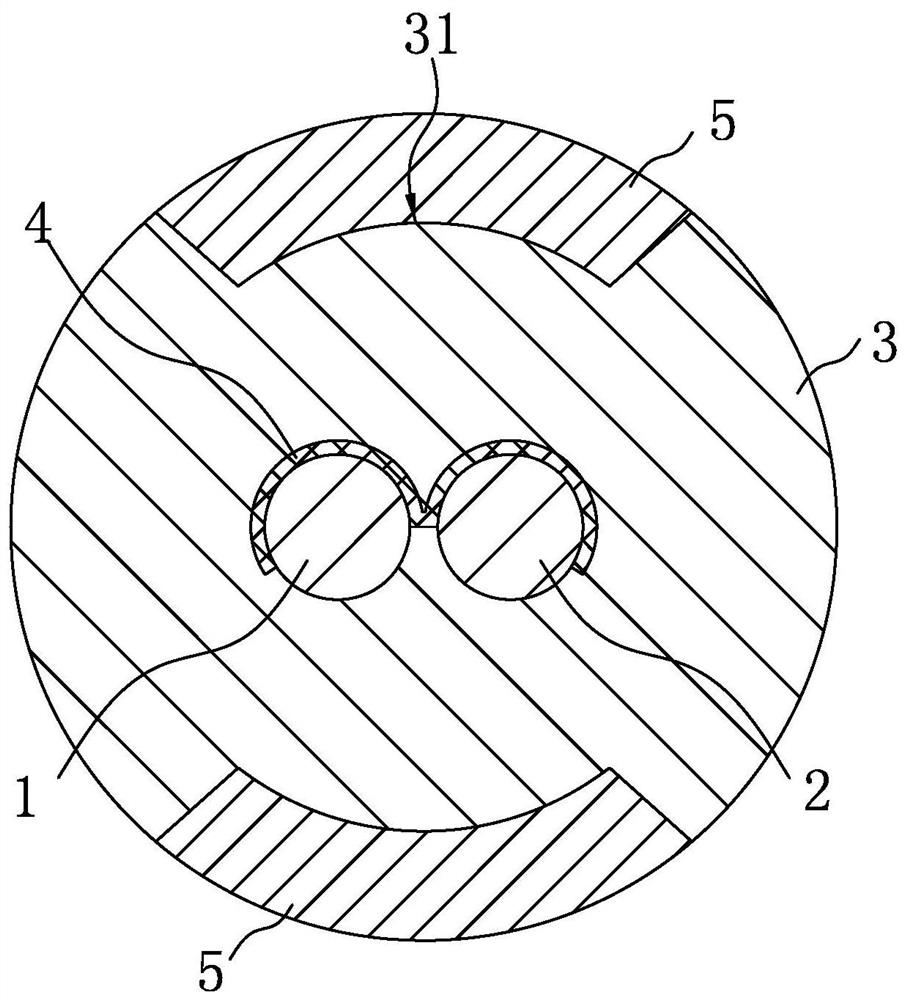

[0038] A rope end fixing piece 4 embedded in the rope end fixing portion 3 and keeping the first rope end 1 and the second rope end 2 flat, wherein the rope end fixing piece 4 is made of metal;

[0039] The rope end fixing piece 4 has an open "∞" ring structure, which clamps the first rope end 1 and the second rope end 2; specifically, the rope end fixing part 3 has a cylindrical structure, The first rope end 1 and the second rope end 2 are fixed on the axial ends of the cylindrical structure;

[0040] This technical solution adopts the structure of sett...

Embodiment 2

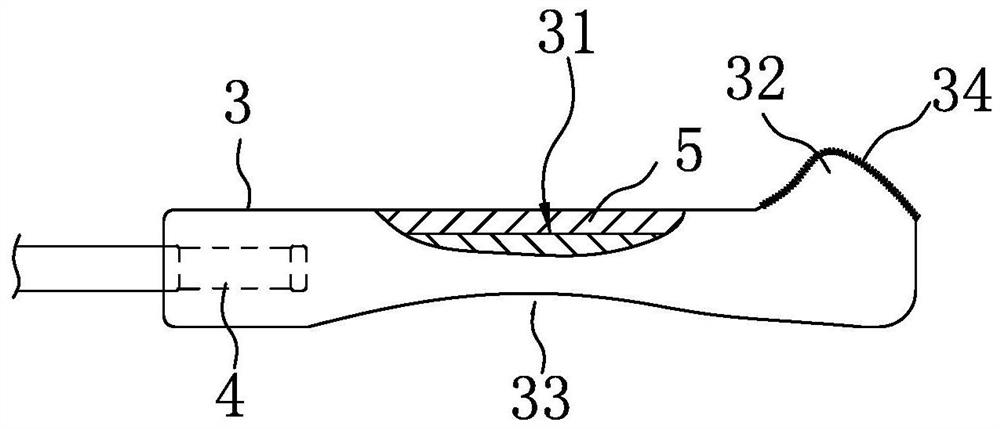

[0048] refer to image 3, compared with Embodiment 1, a pull tab structure with different shapes is designed, specifically: the rope end fixing part 3 has a long strip structure with a rounded rectangle in cross section, and its upper and lower ends are provided for Finger-pulled protrusion 32 and arc-shaped groove 33; this structure improves the convenience and anti-slip performance when pulling;

[0049] At the same time, in order to strengthen this effect, the end of the rope end fixing part 3 away from the first rope end 1 and the second rope end 2 is provided with an anti-skid pattern 34, specifically, the anti-skid pattern 34 is located on the the outer surface of the protrusion 32;

[0050] Corresponding improvements need to be made on the internal structure, specifically, the rope end fixing piece 4 is embedded between the end of the rope end fixing part 3 and the arc-shaped groove 33; this reduces the rope end fixing piece 4, but the resin structure at the rear also...

Embodiment 3

[0052] refer to Figure 4 Compared with Embodiment 1, another structure is designed, specifically, the rope end fixing piece 4 is partially embedded in the rope end fixing part 3; this structure is to ensure that the first rope end 1, The connection between the second rope end 2 and the rope end fixing part 3 is tight, which avoids the separation of the joint between the first rope end 1 and the second rope end 2, and also avoids separation of the pull cord and the resin rope end fixing part 3. The situation arises.

[0053] At the same time, the basic production method of the corresponding pull tab structure is shown here, a production method of the pull tab of the sportswear zipper, comprising the following steps:

[0054] a. Take a continuously conveyed stay rope, and simultaneously set an injection mold with a molding cavity;

[0055] b. Fix the end of the pull rope for continuous conveying;

[0056] c. A pull-out mechanism is set to pull the stay rope out along the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com