Split type floor and production method thereof

A split-type, floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of troublesome floor removal, easy damage to floor heating and various pipes, time-consuming and labor-intensive, etc., to achieve fast replacement operations and simple paving. Convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

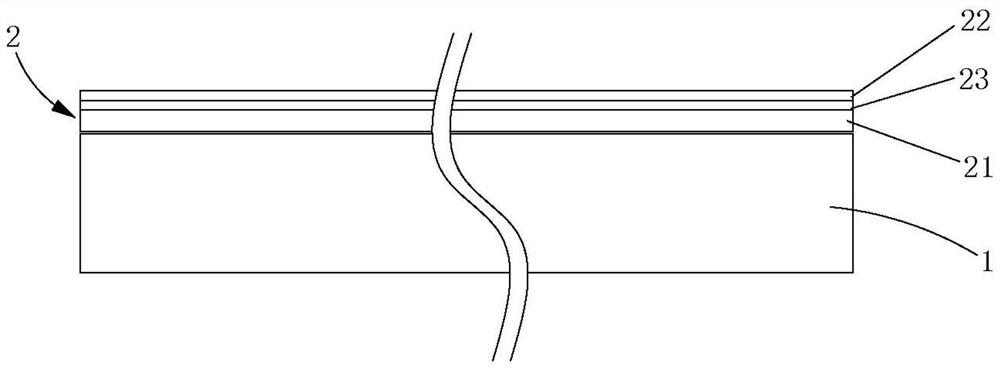

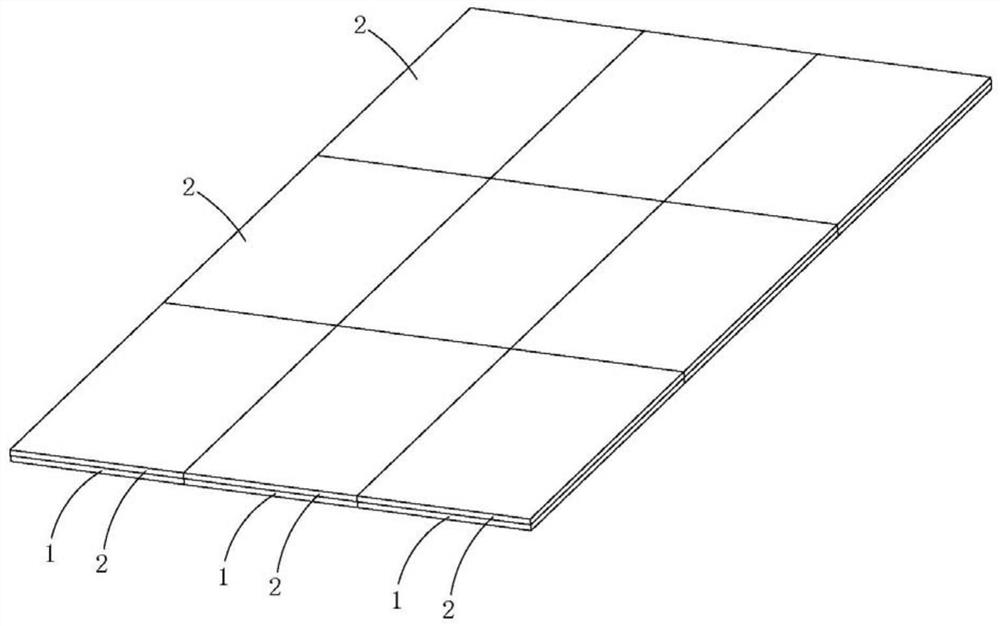

[0046] a split floor, Figures 1 to 4As shown, it includes a split base plate 1 for paving and fixing on the ground and a split decorative panel 2 that is independently set apart from the split base plate 1. The top surface of the split base plate 1 is set to be used for paving the split decorative panel. 2, the top surface of the split bottom plate 1 is a flat and smooth plane, the bottom surface of the split decorative panel 2 is compounded with a self-priming medium layer 21, and the split decorative panel 2 is paved and fixed on the split-type decorative panel 2 through the self-priming medium layer 21. The top surface of base plate 1.

[0047] The split decorative panel 2 comprises a panel base material 23 and a surface wear-resistant layer 22 compounded on the top surface of the panel base material 23, and the surface wear-resistant layer 22 comprises a pattern layer compounded on the top surface of the panel base material 23 and a pattern layer compounded on the pattern...

Embodiment 2

[0065] A production method of a split floor, Figures 1 to 3 shown, including the following steps,

[0066] In the plate production step, respectively produce the split bottom plate 1 whose size and specification is a large plate specification and the split decorative panel 2 whose size and specification are a large plate specification as described in Embodiment 1;

[0067] Large-slab compounding step, absorbing or adhering the split-type decorative panel 2 of the large-slab specification to the surface of the split-type bottom plate 1 of the same size specification to obtain a split-type floor slab whose size specification is the large-slab specification;

[0068] The slab cutting step is to cut the split floor slab into a finished split floor whose size is equal to or close to that of the finished split floor;

[0069] The post-processing step is to carry out post-processing treatment. The post-processing treatment includes at least one of groove forming processing, mechani...

Embodiment 3

[0073] A production method of a split floor, Figures 1 to 4 shown, including the following steps,

[0074] In the plate production step, respectively produce the split bottom plate 1 whose size and specification is a large plate specification and the split decorative panel 2 whose size and specification are a large plate specification as described in Embodiment 1;

[0075] The large-slab cutting step is to cut the split floor 1 of the large-slab specification and the split-type decorative panel 2 of the large-slab specification into sub-slabs and surface layers whose dimensions are equal to or close to those of the finished split floor plate small plate;

[0076] The post-processing step is to carry out post-processing treatment on the small board of the bottom layer or the small board of the surface layer. The post-processing treatment includes at least one of the groove and tenon forming processing, mechanical trimming processing and maintenance treatment. The groove and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com