PVC (Polyvinyl Chloride) latch floor board

A floor and lock technology, which is applied in the direction of floors, buildings, building structures, etc., can solve problems such as seams and lock floor connection failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

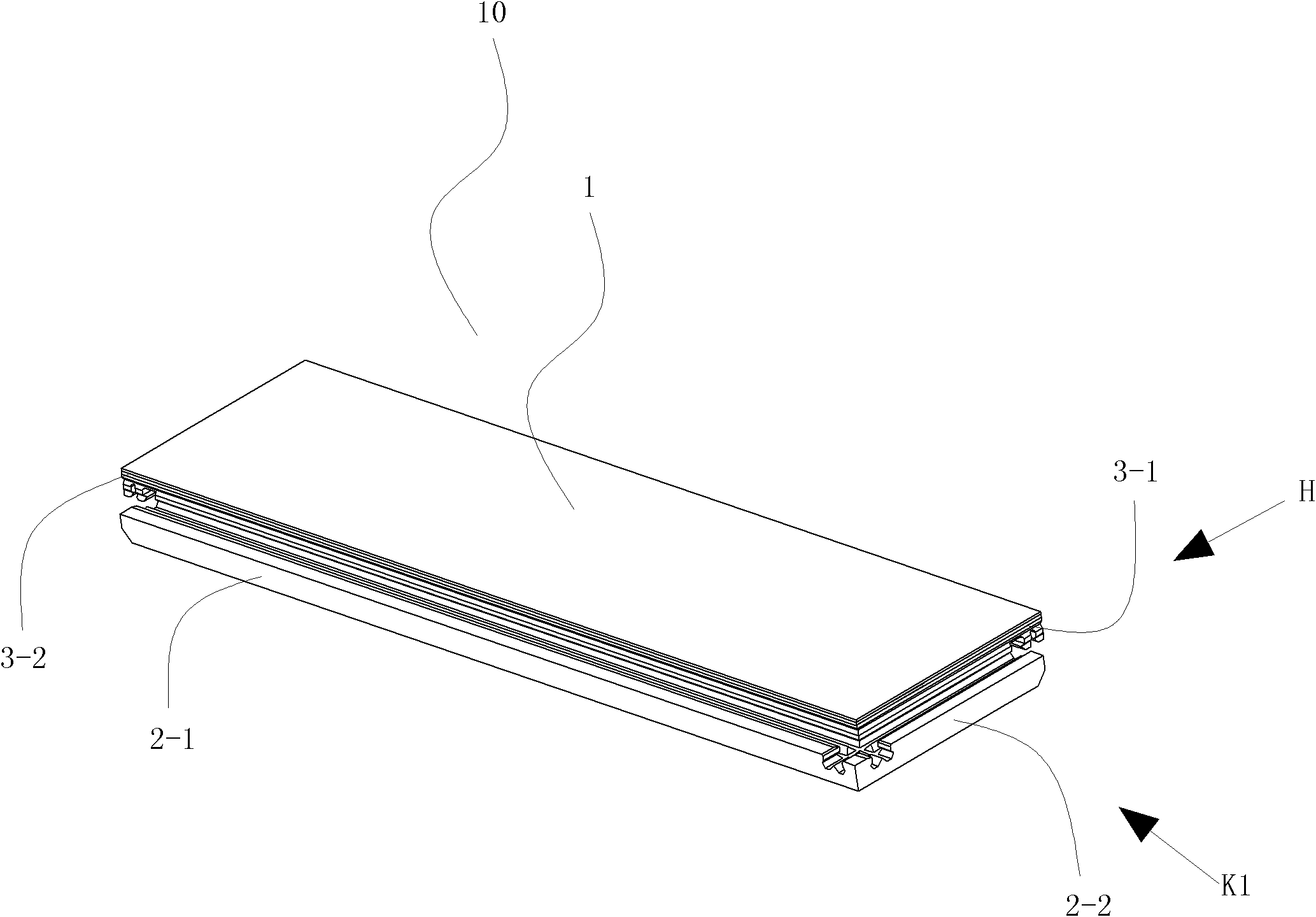

[0079] The description orientation of this embodiment is according to figure 1 The up, down, left, and right directions shown are described, that is, the width direction of the floor is the left and right direction, the thickness direction of the floor is the up and down direction, and the length direction of the floor is the front and rear direction (ie figure 1 The lower left is the front side, figure 1 The upper right is the rear side), the direction close to the center of the floor is called the inner side, and the direction away from the center of the floor is called the outer side. The two-dot dash line in the figure is a schematic boundary line between each part.

[0080] See figure 1 and Figure 4 , the PVC locking floor 10 of this embodiment includes a floor body 10-1, a decorative pattern 10-2-1 and a transparent wear-resistant layer 10-2-2; the decorative pattern layer 10-2-1 is fully covered and fused to the floor body On the upper surface of 10-1, the tran...

Embodiment 2)

[0108] The rest of this embodiment is the same as that of Embodiment 1, except that the inner lower part of the inner tongue 33 of the elastic double tongue portion is provided with a bow-shaped inner convex portion 33-1 with a cross-sectional shape that protrudes inward (see Figure 15 ). The inner-outward distance L3 of the inner convex portion 33 - 1 is 0.24 to 1 mm (0.3 mm in this embodiment). The outer lower part of the outer tongue 34 is provided with a bow-shaped outer convex part 34-1 with a cross-sectional shape facing inwardly (see Figure 15 ). The outward-inward distance L4 of the convex portion 34 - 1 is 0.24 to 1 mm (0.3 mm in this embodiment).

[0109] See Figure 14 The cross-sectional shape of the inner tongue limiting groove 24-2-1 of the lock main groove 24 of the groove seat part 2 is an opening corresponding to the cross-sectional shape of the inner tongue 33 of the elastic double tongue part 3. Bows facing inward. The cross-sectional shape of the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com