Dry-method paving process for wall tiles

A ceramic tile, dry method, applied in covering/lining, construction, building structure, etc., can solve the problems of long construction period, low construction efficiency, high technical requirements of workers, and achieve firm paving, high paving accuracy, The effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

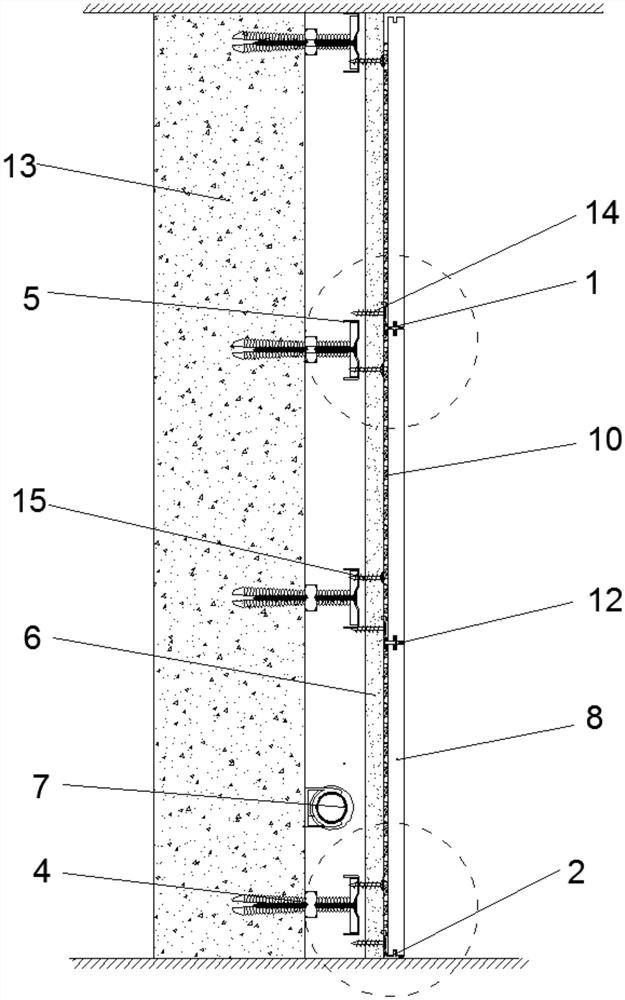

[0038] A dry laying process of wall tiles, comprising the following steps:

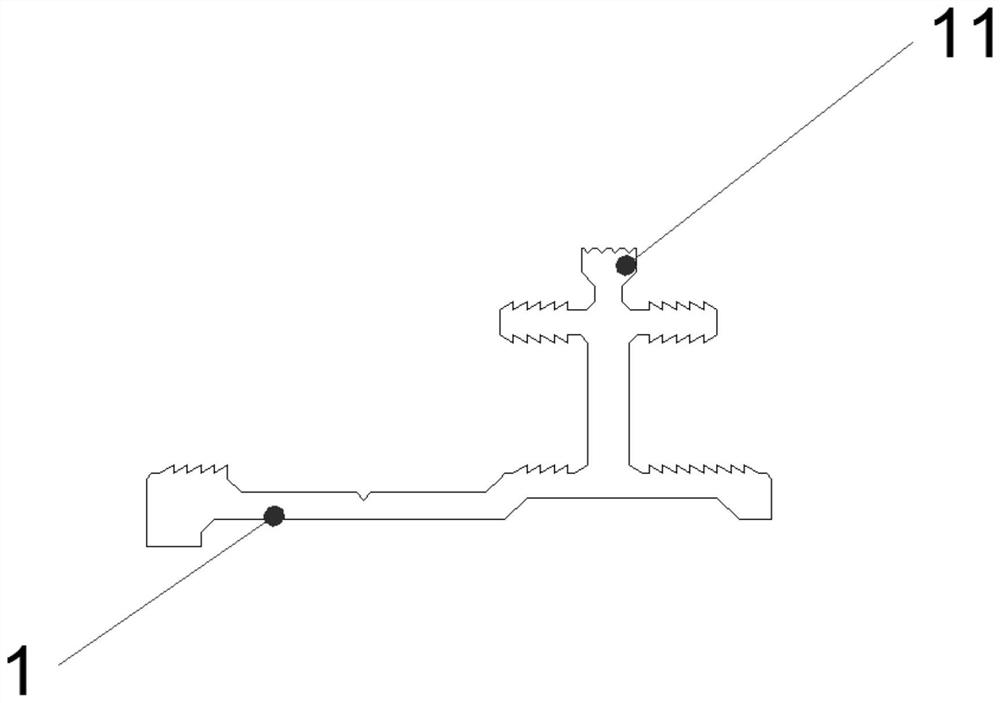

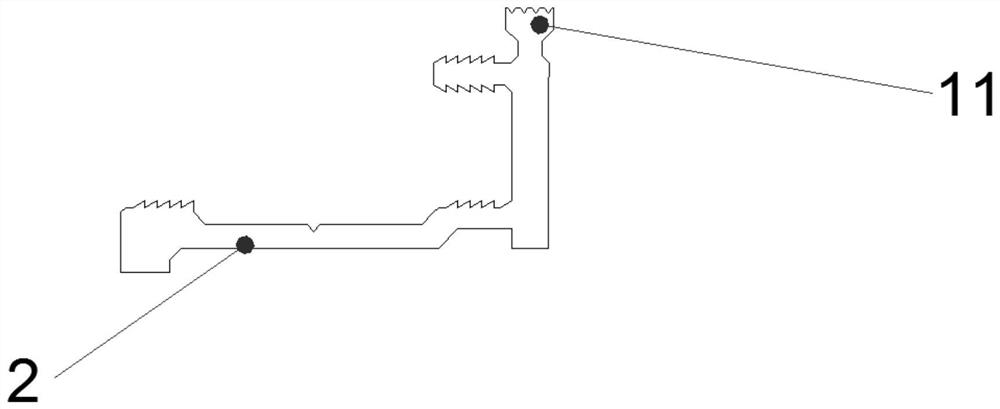

[0039] S1, position and open holes on the original building wall, install the leveling expansion mechanism on the original building wall, install the leveling keel on the leveling expansion mechanism, the leveling expansion mechanism includes expansion thread sleeves, fastening screws, positioning When installing, first fix the expansion threaded sleeve in the original building wall, and install the leveling keel on the expansion threaded sleeve through the fastening screw. When the fastening screw penetrates into the original building wall, the expansion threaded sleeve gradually Expand and expand, and then cooperate with tightening the positioning nut to make the expansion thread sleeve firmly fixed in the original building wall;

[0040] S2, install the leveling base on the leveling keel through the base connecting screws, adjust the leveling expansion mechanism and the leveling keel, and ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com