A display panel automatic loading and unloading device

A display panel and equipment technology, applied in the field of display panel automatic loading and unloading equipment, can solve problems such as low cleaning quality and efficiency, low degree of automation, and increased costs, so as to improve functionality and scope of application, and accurately place and unload display panels , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0032] see Figure 1-7 , the present invention provides a technical solution:

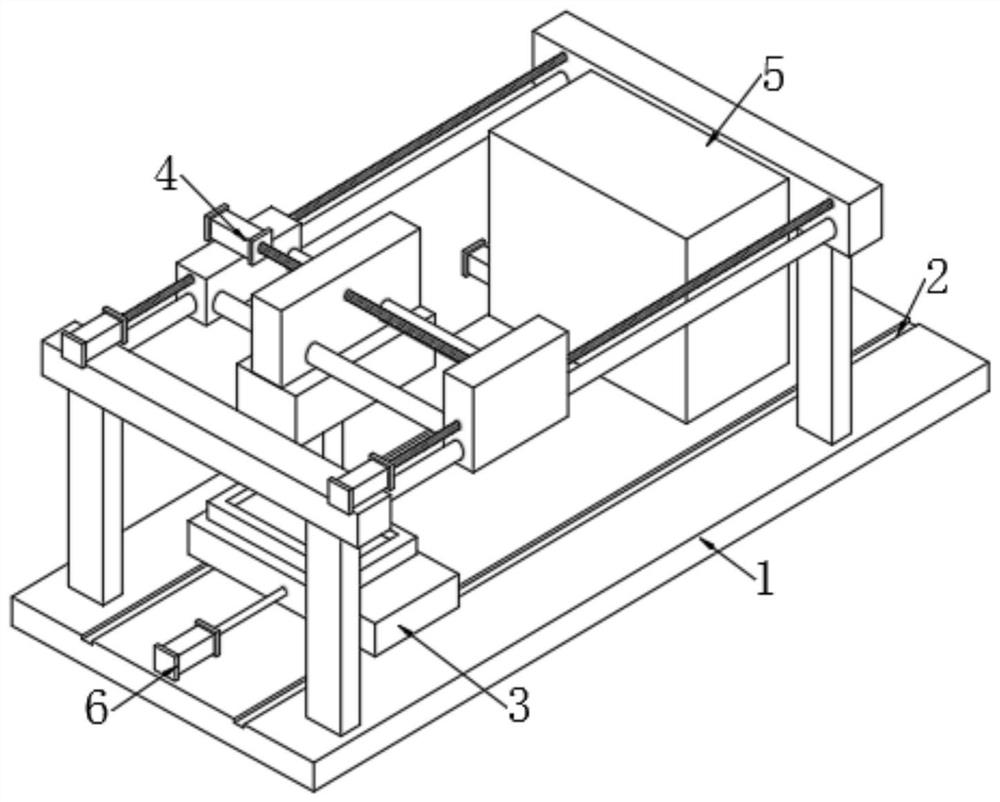

[0033] An automatic display panel loading and unloading device, comprising a workbench 1, two symmetrically distributed slide rails 2 are provided on the upper surface of the workbench 1, and a placement component 3 is arranged above the slide rails 2;

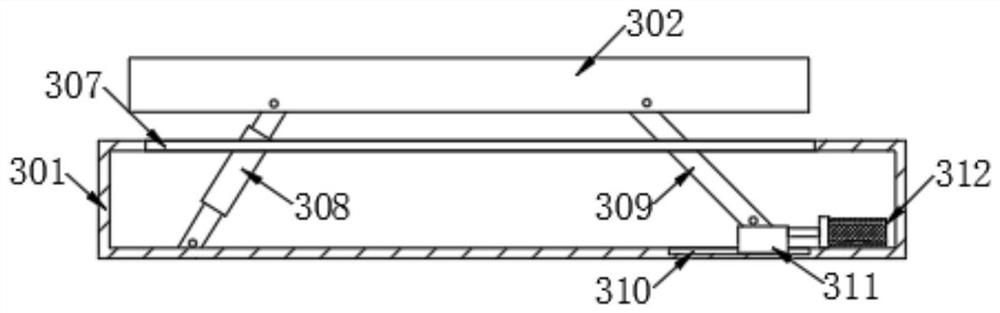

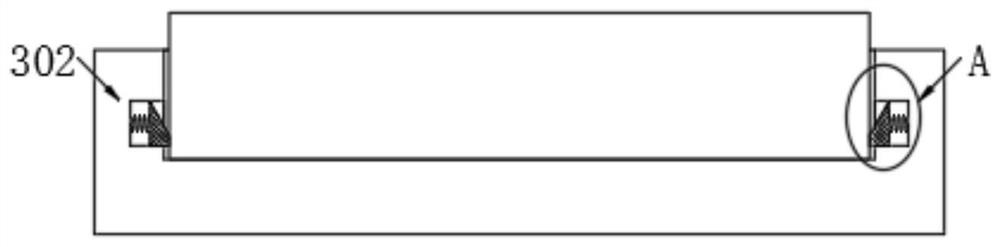

[0034] The placement assembly 3 includes a lift chamber 301 that is slidingly connected to the slide rail 2. A placement plate 302 is provided above the lift chamber 301. A placement groove 303 is provided on the upper surface of the placement plate 302. A display panel is placed inside the placement groove 303, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com