Structural design and manufacturing method of suit collar

A technology of structural design and production method, applied in the field of clothing, can solve the problems of wrinkling, affecting the bid winning rate and workshop rework rate, unevenness at the front neckline, etc., so as to reduce production costs and time costs, labor costs and service costs. The effect of reducing and shortening the ironing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] See figure 1 , figure 2 , image 3 ,Figure 4 , Figure 5 with Image 6 , The structure of the Sikikifold collar, including the following steps:

[0043] Step S1, draw the collar, led the template and foot-style model based on the desired suit.

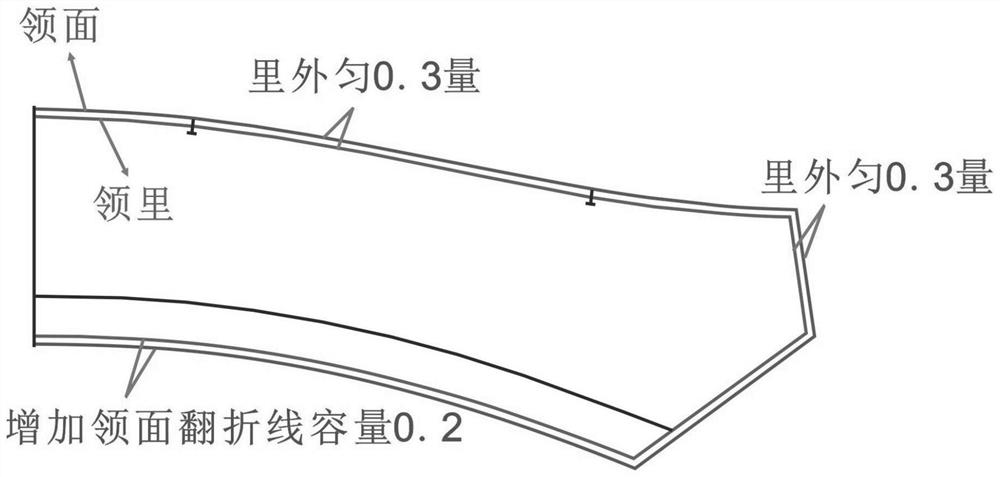

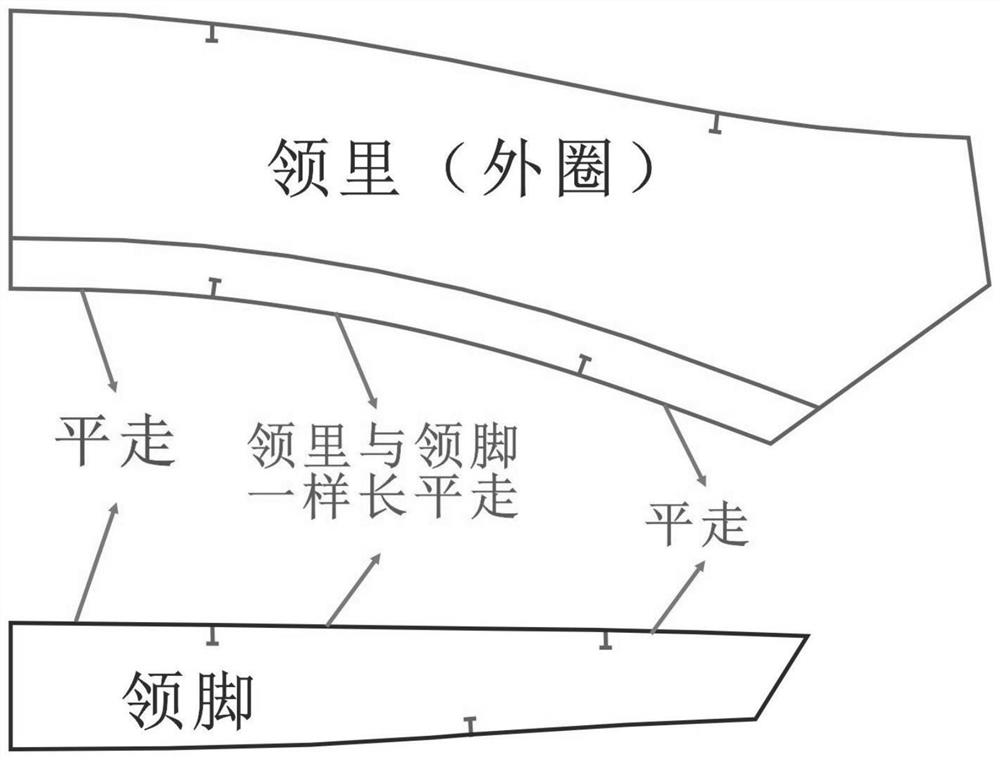

[0044] Step S2, see figure 1 Adjust the collar, lead the arc length in the inside and outside of the model. When the design of the model is laminated with the leader, there is a certain gap between the leadership line and the termination line under the line as a collar capacity. The collar folding line capacity is 0.2 cm. Leading lines and gaps on the termination lines on the termination lines as the terminal stop. The length of the tandem homogenization is 0.3 cm. There is a certain gap between the corner of the leader and the corner of the corner as a collar. The collar refundment amount is 0.3cm. The width between the led line and the termination line in the termination line is greater than the width between the line and the leader ...

Embodiment 2

[0050] See Image 6 The neutral line is broken in the neckline. The continence is divided into two pieces of symmetrical, and suture the noodles in both sides. By breaking in the general, and change the yarn to an oblique yarn, improve the verticality.

[0051] As a preferred, the yarn is a 45 ° oblique yarn. The oblique margin is better, and the verticality is better, and the length of the outer ring is increased.

[0052] As a preferred, the surface of the surface of the surface is a gauze. Leadership surface yarn towards the yarn. The foot is changed to a cross-yarn, prevents large, preventing collar deformed. The surface of the front yarn and the necklace of the neck are mutually cooperated with each other to improve the deformation performance.

[0053] As a preferred, the neck material, the neck material and the foot fabric are both a spinning fabric. By disintertoring the tinning lining, increasing the tanguity of the collar, the collar is broken, changed to the slanting, an...

Embodiment 3

[0055] The structural design and fabrication method of a suite of the present invention includes the following steps:

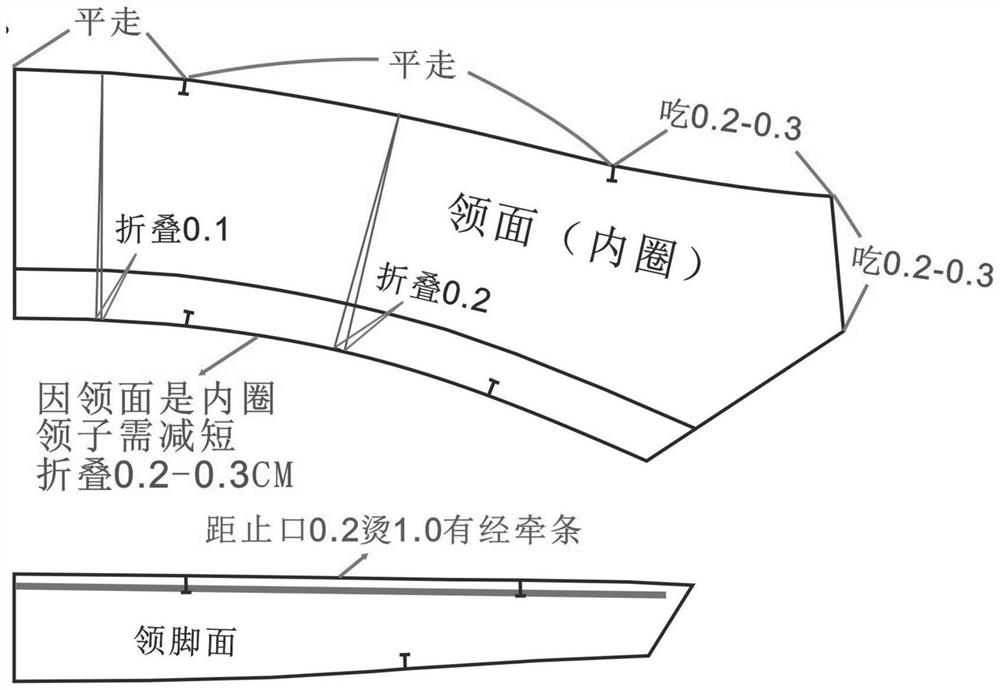

[0056] Step S1, draw the collar, led the template and foot-style model based on the desired suit.

[0057] Step S2, adjust the collar, lead the arc length in the inside of the model. When the design of the model is laminated with the leader, there is a certain gap between the leadership line and the termination line under the line as a collar capacity. The collar folding line capacity placed width is 0.1 cm. Leading lines and gaps on the termination lines on the termination lines as the terminal stop. The length of the homogeneous portion is 0.2 cm. There is a certain gap between the corner of the leader and the corner of the corner as a collar. The collar refundment amount is 0.2cm. The width between the led line and the termination line in the termination line is greater than the width between the line and the leader in the leader. Because after the column is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com