Non-uniform tubular MA transmutation rod with reactor core axial power flattening function

An axial power and non-uniform technology, applied in the direction of moderator/core structure, reactor, nuclear power generation, etc., can solve the problem of low direct fission rate and achieve the effect of improving the power peak shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

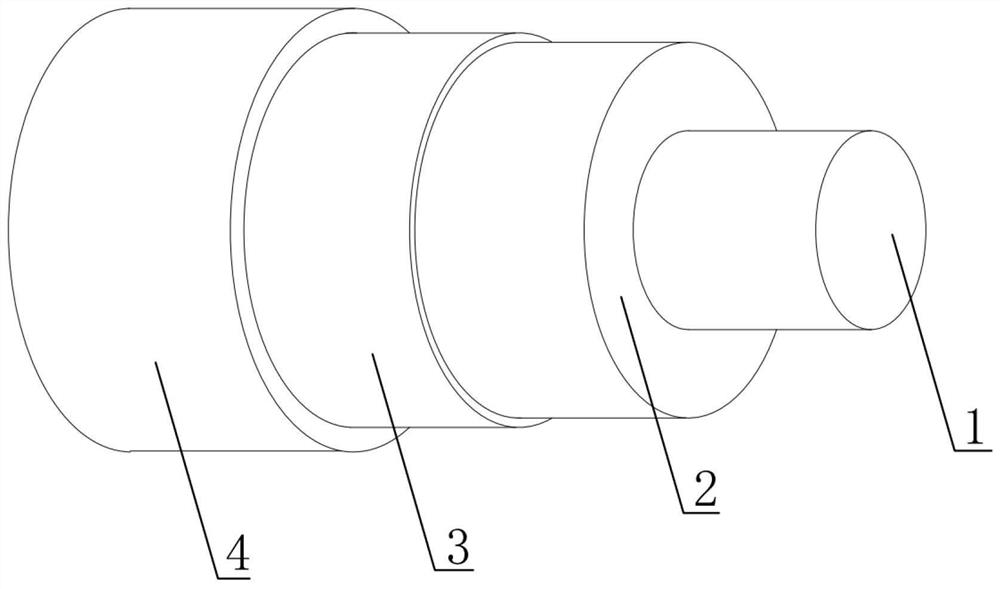

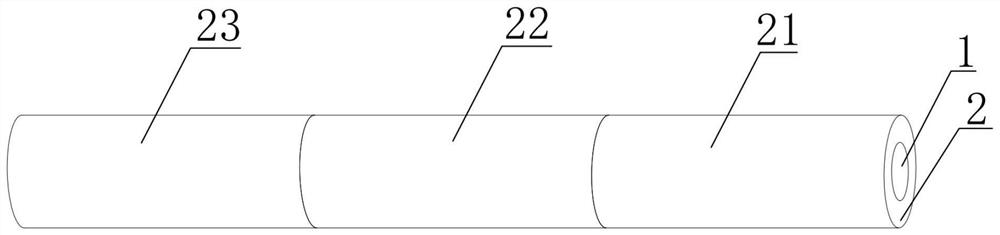

[0053] Such as figure 1 with figure 2 Shown: the non-uniform tubular MA transmutation rod with the function of flattening the axial power of the core provided by this embodiment, its structure includes:

[0054] Central layer 1, which is located in the center of the non-uniform tubular MA transmutation rod, and the outside of the central layer 1 is provided with 6 LiD / MA / UO 2 Mixed fuel layer 2, the wall thickness of the non-uniform tubular MA transmutation rod is 0.1cm, the 6 LiD / MA / UO 2 The outside of the mixed fuel layer 2 is provided with an air gap layer 3, and the outside of the air gap layer 3 is provided with a zirconium alloy cladding 4;

[0055] The non-uniform tubular MA transmutation rod is provided with three sections in the axial direction 6 LiD / MA / UO 2 Mixed fuel layer, and two adjacent sections 6 LiD / MA / UO 2 The mass fraction of MA nuclides in the mixed fuel layer is different, from the upper end to the middle position of the non-uniform tubular MA tra...

Embodiment 2

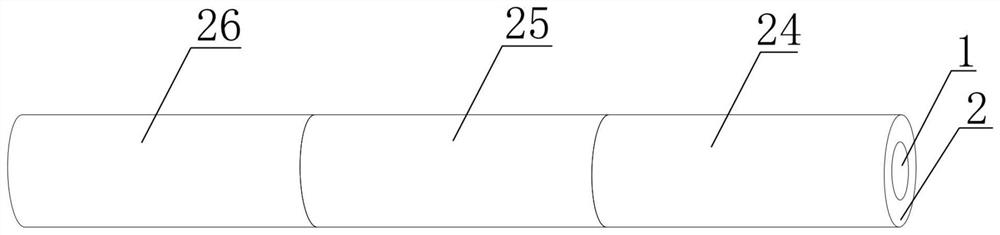

[0057] Such as figure 1 with image 3 As shown, the non-uniform tubular MA transmutation rod with the function of flattening the axial power of the core in this embodiment has a structure comprising:

[0058] Central layer 1, which is located in the center of the non-uniform tubular MA transmutation rod, and the outside of the central layer 1 is provided with 6 LiD / MA / UO 2 Mixed fuel layer 1, the wall thickness of the non-uniform tubular MA transmutation rod is 0.1cm, the 6 LiD / MA / UO 2 The outside of the mixed fuel layer 2 is provided with an air gap layer 3, and the outside of the air gap layer 3 is provided with a zirconium alloy cladding 4;

[0059] The non-uniform tubular MA transmutation rod is provided with three sections in the axial direction 6 LiD / MA / UO 2 Mixed fuel layer, and two adjacent sections 6 LiD / MA / UO 2 The mass fraction of MA nuclides in the mixed fuel layer is different, from the upper end to the middle position of the heterogeneous tubular MA trans...

Embodiment 3

[0061] Such as figure 1 with Figure 4 As shown, the non-uniform tubular MA transmutation rod with the function of flattening the axial power of the core in this embodiment includes:

[0062] Central layer 1, which is located in the center of the non-uniform tubular MA transmutation rod, and the outside of the central layer 1 is provided with 6 LiD / MA / UO 2 Mixed fuel layer 2, the wall thickness of the non-uniform tubular MA transmutation rod is 0.1cm, the 6 LiD / MA / UO 2 The outside of the mixed fuel layer 2 is provided with an air gap layer 3, and the outside of the air gap layer 3 is provided with a zirconium alloy cladding 4;

[0063] The non-uniform tubular MA transmutation rod is provided with five sections in the axial direction 6 LiD / MA / UO 2 Mixed fuel layer, from the upper end to the lower end of the non-uniform tubular MA transmutation rod is recorded as the first section 6 LiD / MA / UO 2 Mixed fuel layer 27, the second section 6 LiD / MA / UO 2 Mixed fuel layer 28, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com