Ice shape measuring device and measuring method for icing wind tunnel test

A measuring device and a technology for wind tunnel testing, applied in the field of wind tunnel testing, can solve the problems of inability to accurately measure the ice shape position to be measured, waste of test materials, long preparation process for ice shape measurement, etc. Simple, reduce the effect of test consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

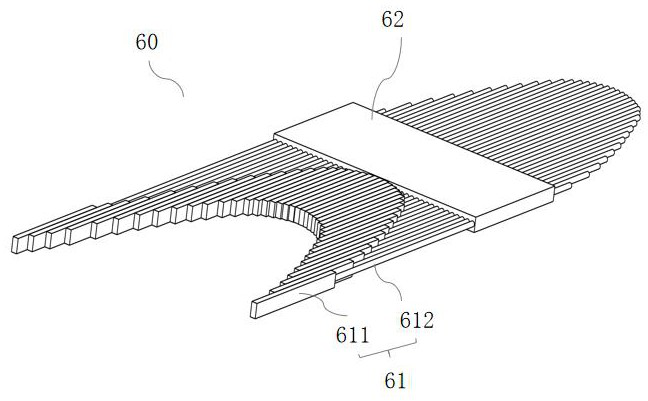

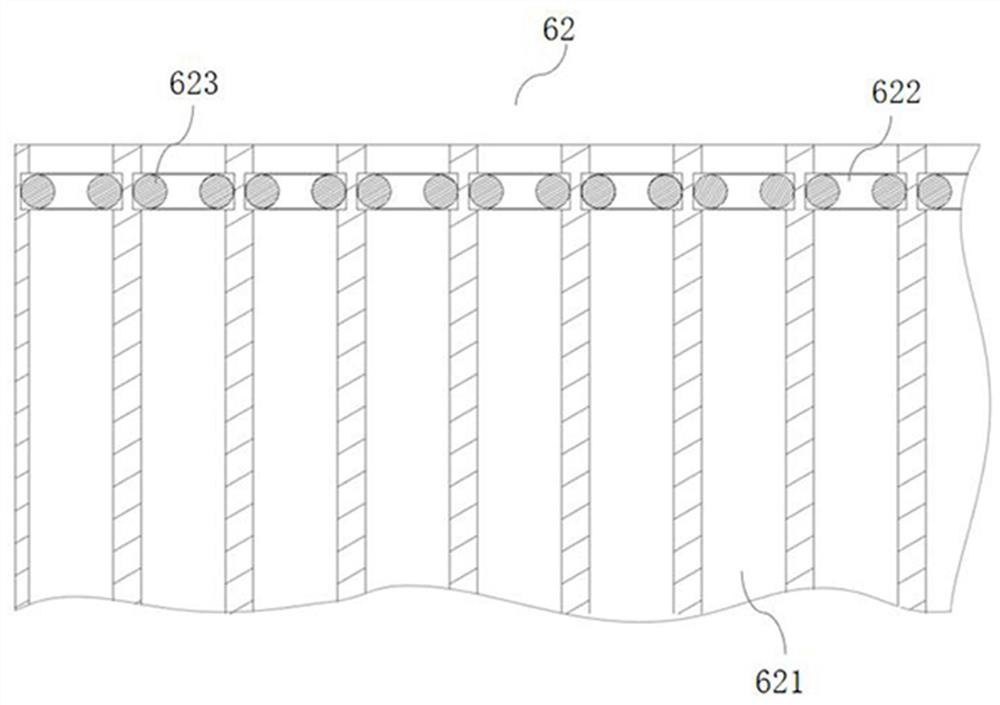

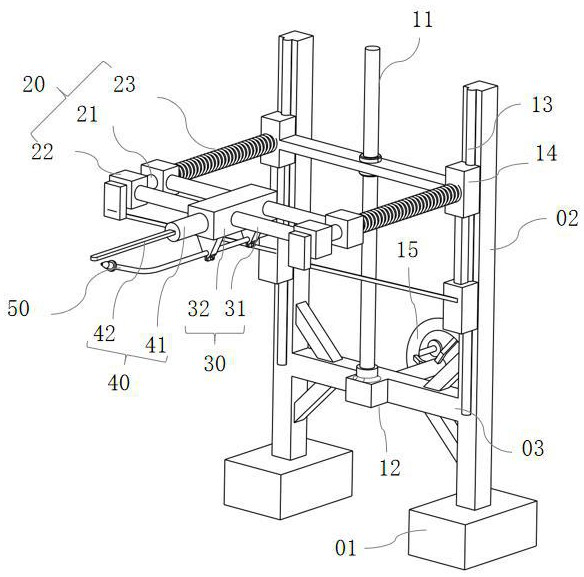

[0041] An icing wind tunnel test ice shape measurement device, such as figure 1 , figure 2 As shown, it includes an inserting board 62 and a plurality of pins 61; the inserting pins 61 include a square tube section 611 and a round tube section 612 fixedly connected to each other; a plurality of pin holes 621 are arranged side by side on the inserting plate 62, and the inserting pins 62 are arranged side by side. The round tube section 612 of the needle 61 passes through the pin hole 621 and can slide in the pin hole 621; the square tube section 611 of a plurality of the pins 61 is located on the same side of the insert plate 62; The upper plane of the square pipe section 611 is coplanar with the upper surface of the inserting plate 62 .

[0042] Thus, during the test, the graph paper is placed on the plane formed by the upper plane of the square pipe section 611 and the upper surface of the inserting plate 62 to prevent the graph paper from being wrinkled and affecting the a...

Embodiment 2

[0047]This embodiment relates to a method for measuring ice shape in an icing wind tunnel test. The ice shape measuring device for an icing wind tunnel test as described in Embodiment 1 is used. Include the following steps:

[0048] S10. cutting the ice shape to obtain the ice shape gap;

[0049] The method of cutting the ice shape is well known in the art, and will not be repeated here, and the ice shape cutting method in Embodiment 4 of the present invention can also be used.

[0050] S20. Adjusting a plurality of pins 61 so that the profiled lines surrounded by the tops of the multiple square pipe sections 611 are the same as the profiled lines of the ice shape acquisition position model to be measured;

[0051] At this time, since the position of the ice shape to be measured has been set in advance, the operator can obtain the profile curve data of the position of the ice shape to be measured according to the profile data of the model, and adjust the pin 61 according to t...

Embodiment 3

[0058] This embodiment relates to a method for measuring ice shape in an icing wind tunnel test, using an ice shape measuring device for an icing wind tunnel test as described in Embodiment 1. The difference from Embodiment 2 is that in this embodiment To measure the ice accretion and ice shape at the temporarily increased measurement position, or when the location of the ice shape to be measured is unknown in advance, the following steps are included:

[0059] S10. cutting the ice shape to obtain the ice shape gap;

[0060] S20. Adjusting a plurality of pins 61 so that the profiled lines surrounded by the tops of the multiple square pipe sections 611 are the same as the profiled lines of the ice shape acquisition position model to be measured;

[0061] At this time, because the profile line of the ice shape acquisition position model to be measured is not known in advance, during the test, the ice shape measuring device 60 is inserted into the cut ice shape gap, and the inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com