On-line sampling, blanking, conveying and weighing device for capsules

A weighing device and capsule technology, which is applied in the direction of measuring devices, weighing equipment and weighing of materials with special properties/forms, can solve problems such as increased labor input costs, low work efficiency, and inability to detect and weigh in real time , to achieve the effect of saving human resources and maintenance time, improving work efficiency and quality, and breaking technology monopoly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

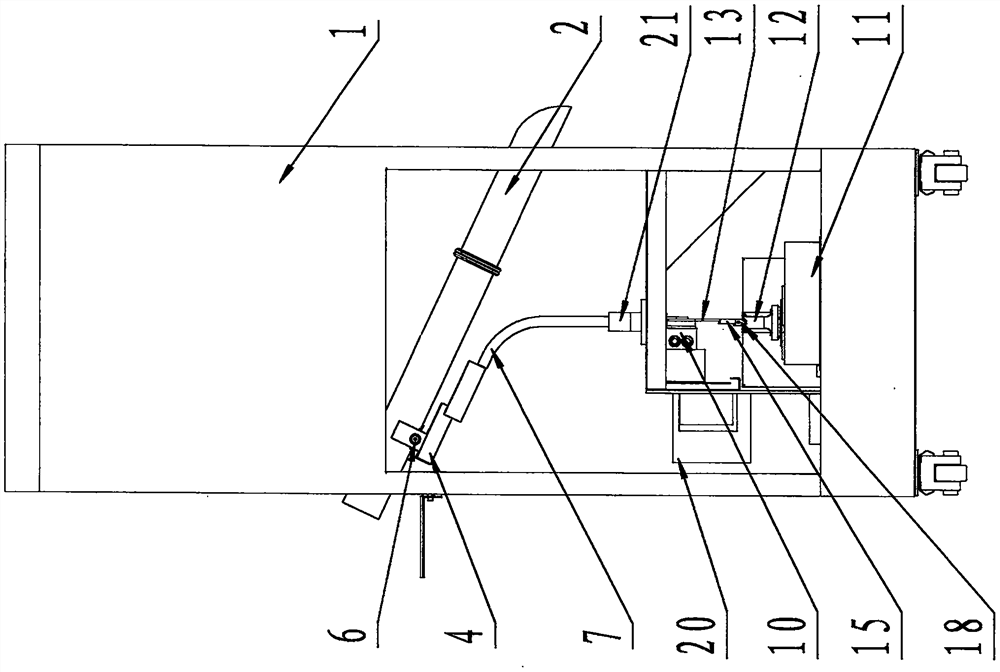

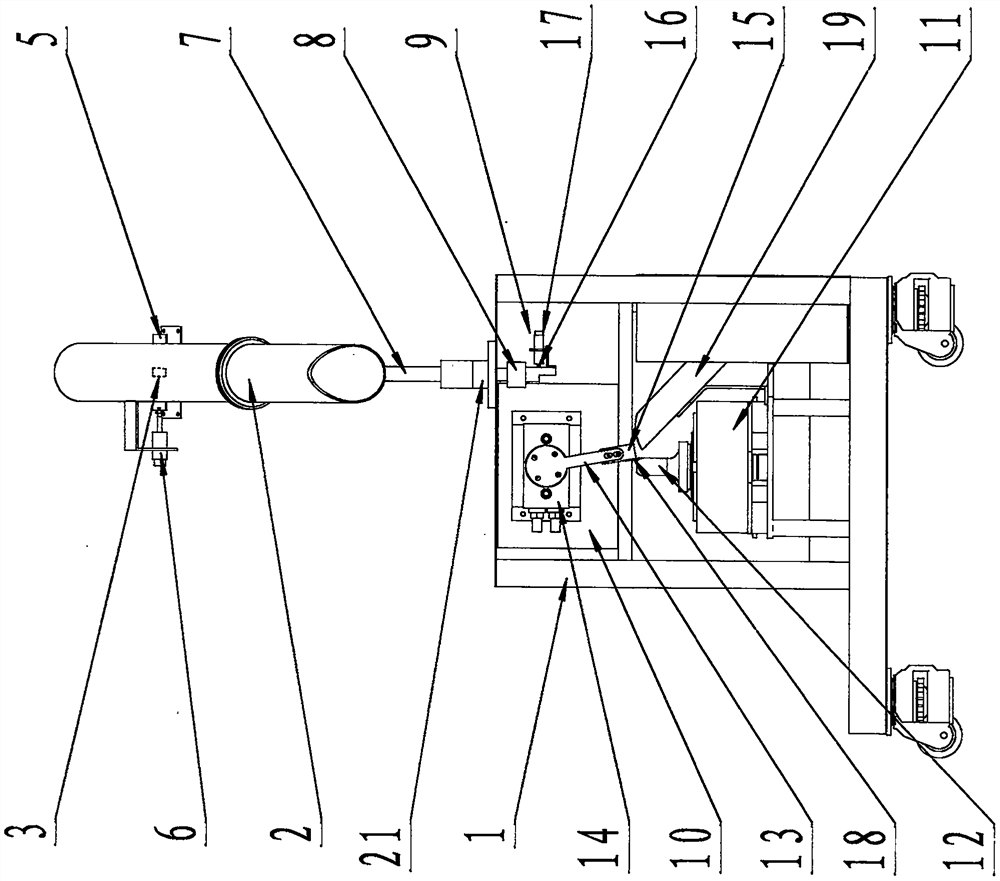

[0010] refer to figure 1 , figure 2 It can be seen that the capsule online sampling and blanking conveying and weighing device of the present invention used in conjunction with the capsule filling machine includes a casing 1 (i.e. a frame), a capsule feeding pipe 2 arranged obliquely downward, and the capsule feeding pipe 2 On the pipe 2, a blanking hole 3 (corresponding to the specification of the capsule) is provided at the feeding position, and in the box 1, a blanking hole 3 is installed below the blanking hole 3 of the capsule feeding pipe 2. Capsule slideway 4, between this capsule slideway 4 and the blanking hole 3 of capsule feeding pipe, sampling discharge plate 5 is housed (also can be provided with the discharge hole corresponding to blanking hole on it, when discharge hole When overlapping with the blanking hole position, the finished capsule to be weighed is realized blanking), the sampling discharge plate 5 is connected to the discharge power source 6 (for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com