Belt shield and belt replacing all-in-one machine method and device

A technology of belt guard and integrated machine, which is applied in the direction of transmission device, engineering safety device, belt/chain/gear, etc. It can solve the problems of rising cost, inability to replace the belt, and inability to install the belt replacement device, etc., achieving strong versatility , low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

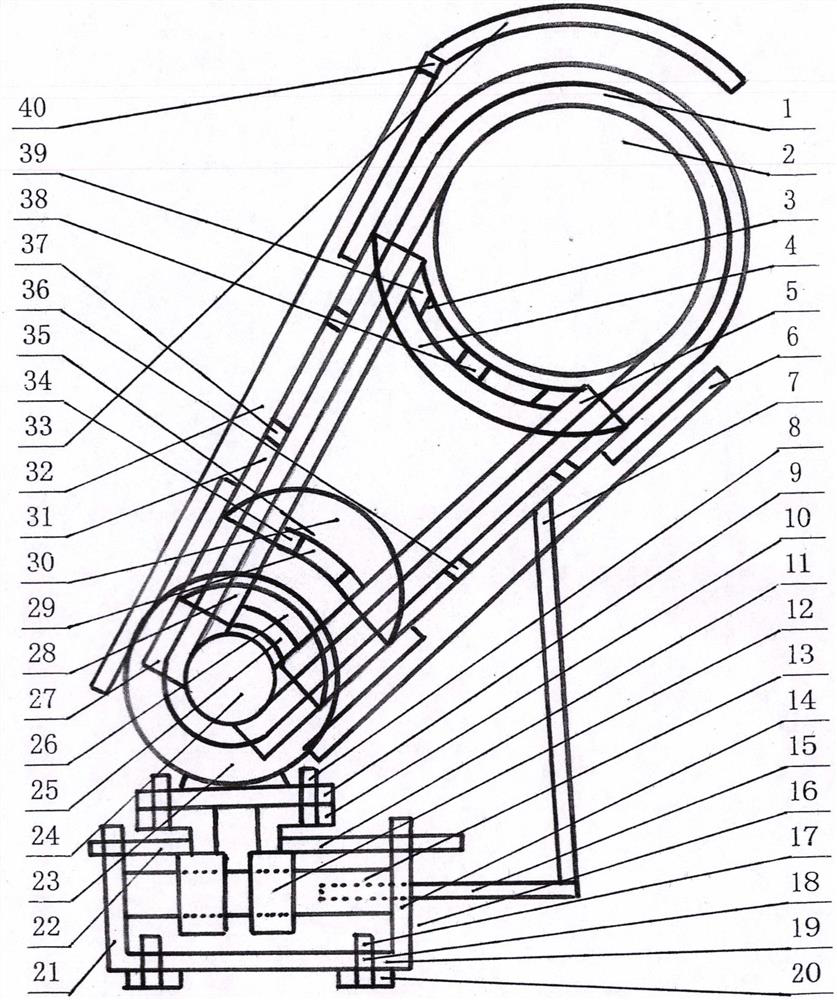

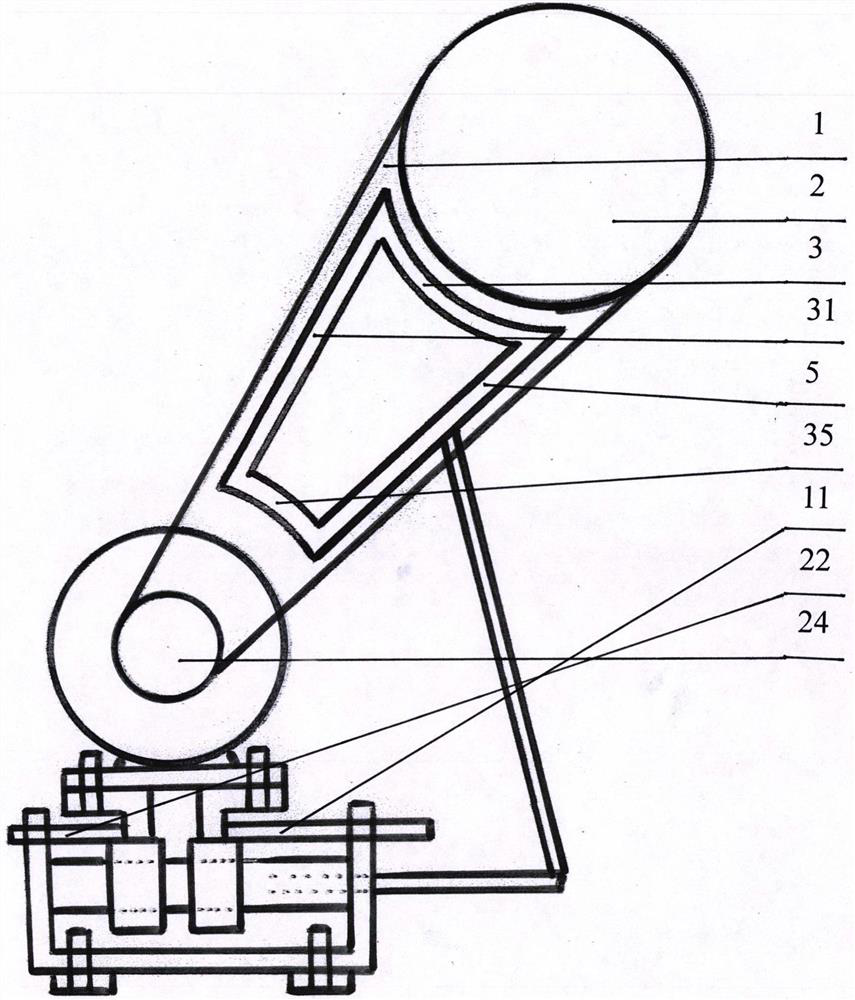

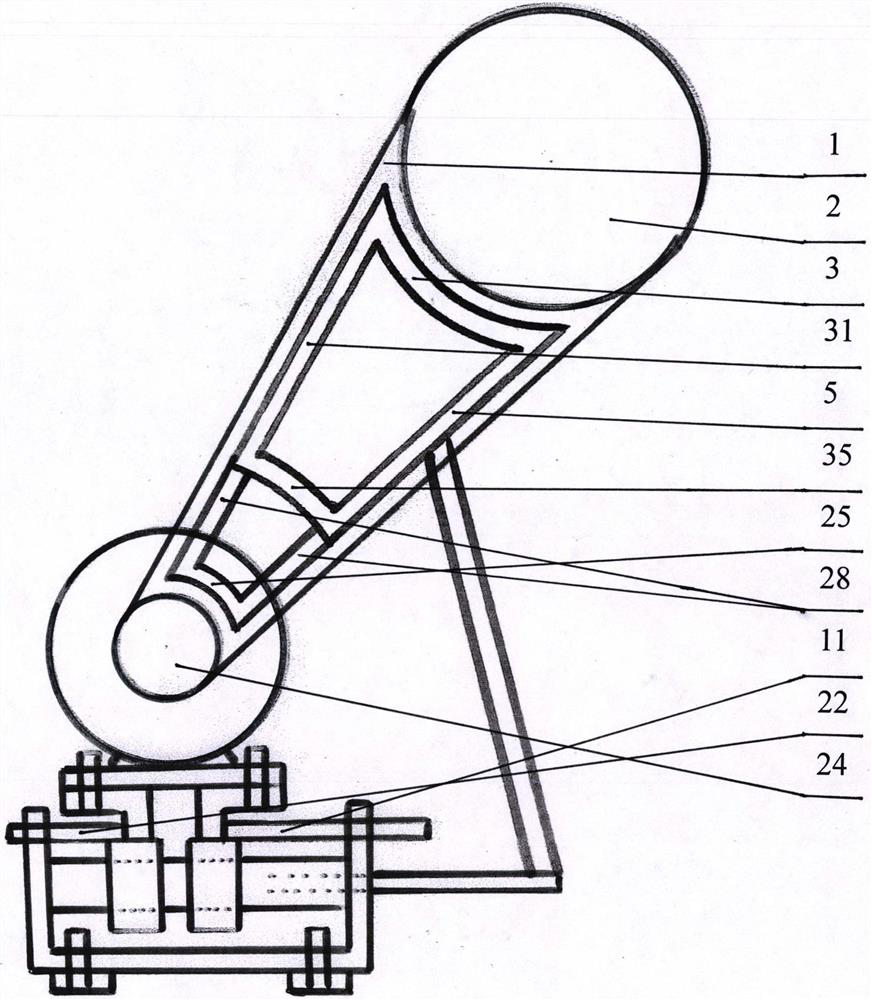

[0014] figure 1 It is a schematic diagram of the overall structure of an all-in-one machine for changing belt guards. Such as figure 1 Shown: on the screw ring 20 there is the same hole as the fixing hole 18 on the base plate 19, and the fixing screw 17 matched with the fixing hole 18 is inserted into the fixing hole 18 and the screw ring 20 to fix the base plate 19, and the base plate 19 is arranged on the force frame 16 , inner side plate 14, outer side plate 21, fixed hole 18 is arranged on base plate 19, movable connecting rod 15, movable column 13, internal fixing screw 11 are arranged on inner side plate 14, movable column 13, outer fixing screw 22 are arranged on outer side plate 21, The movable column 13 fixedly connects the inner panel 14 and the outer panel 21, and the two movable sections 12 are sleeved on the movable column 13, and the two movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com