Pulverized coal and coal cinder cleaning device for coal feeding port of coking furnace, and using method thereof

A technology for cleaning device and coking furnace, applied in the field of coking furnace, can solve the problem of high implementation cost, achieve the effects of reducing waste, eliminating manual cleaning, and having strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the examples.

[0051] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

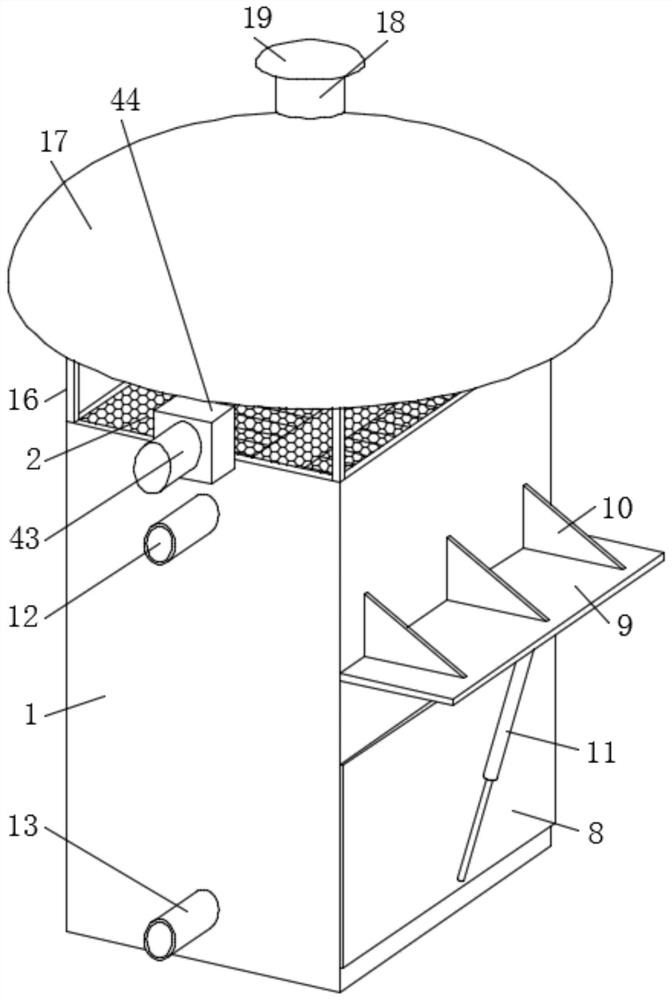

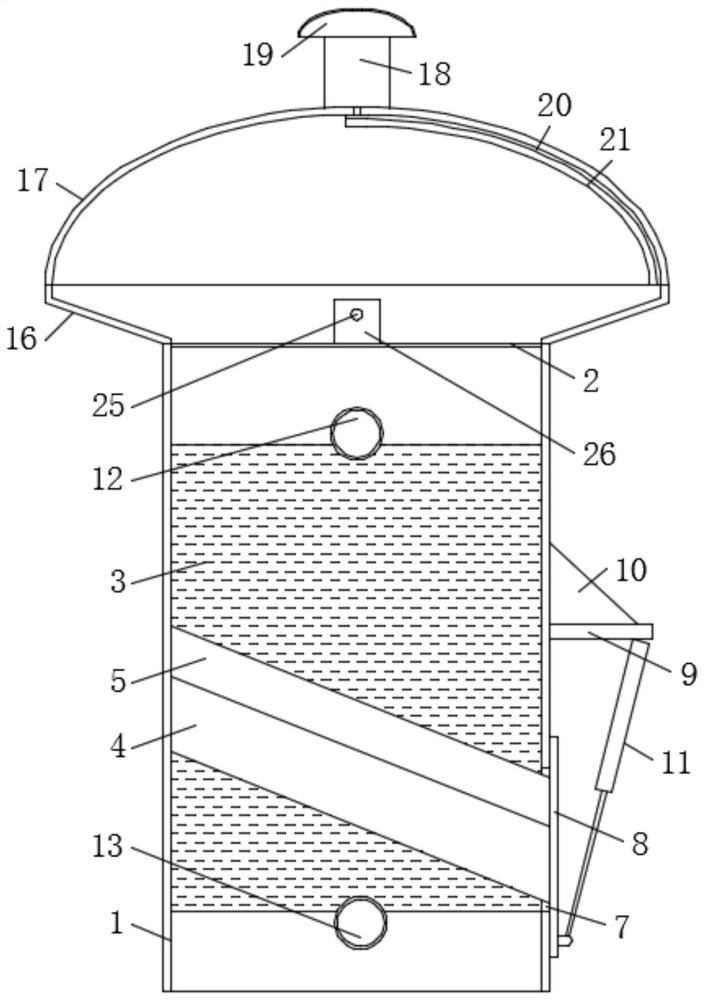

[0052] see Figure 1-12 , the present invention provides a coal pulverized coal slag cleaning device for the coking furnace coal delivery port and its use method, comprising a square cylinder 1, the top of the square cylinder 1 is fixedly installed with a dust removal net 2, and the inside of the square cylinder 1 is fixedly installed with Several fixed plates one 3, several fixed plates one 3 are equidistantly distributed, two adjacent fixed plates one 3 opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com