Novel airtight cabin-penetrating optical fiber connector

An optical fiber connector and airtight technology, which is applied in the field of new airtight through-chamber optical fiber connectors, can solve the problems of poor environmental resistance, easy air leakage, long connector length, etc., achieve good optical effects and ensure airtightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with specific embodiments.

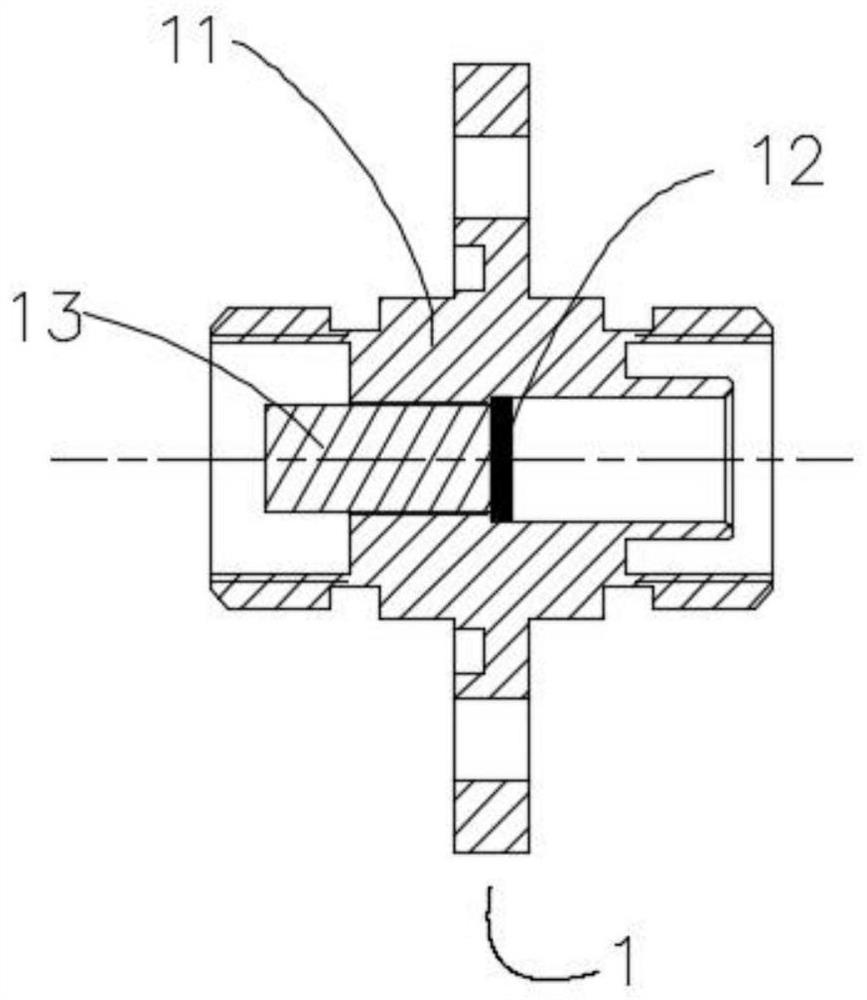

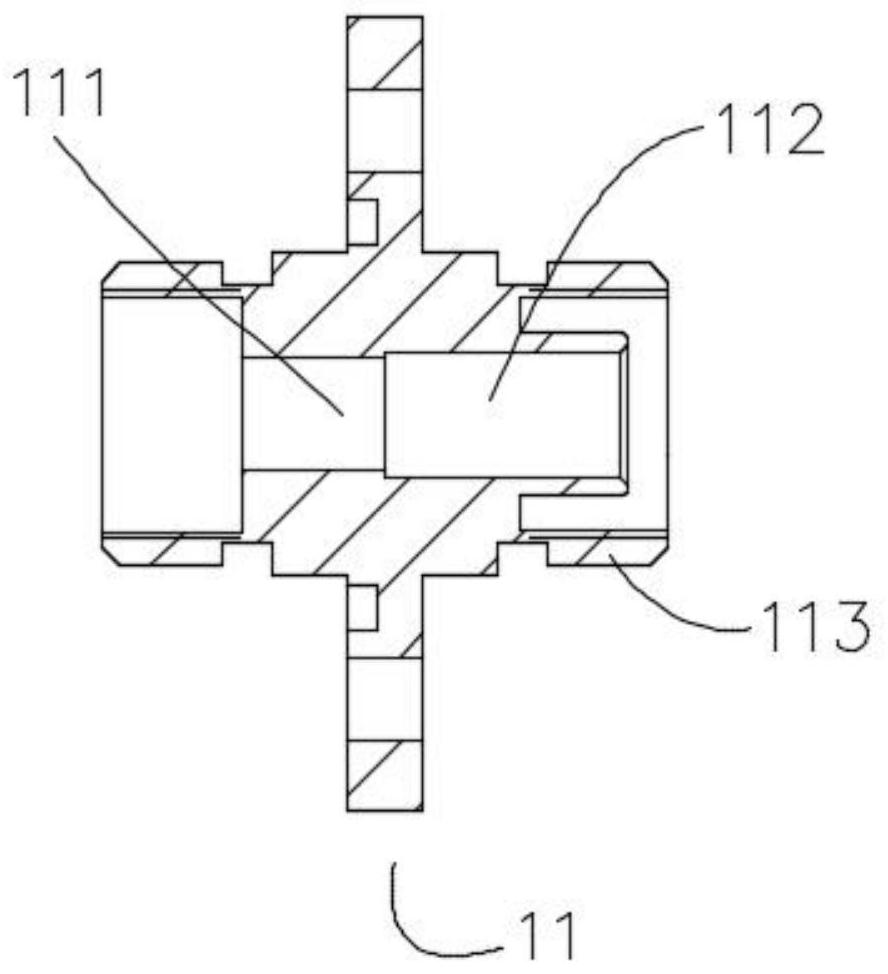

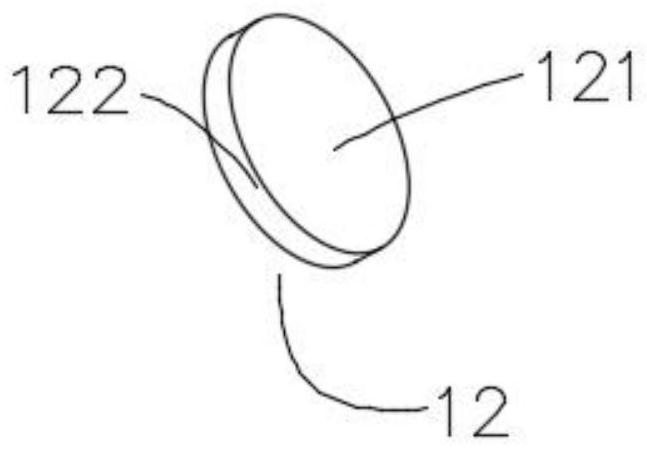

[0030] refer to Figure 1-7 , a new airtight cabin-penetrating optical fiber connector, including a socket 1 and a plug 2. The socket 1 includes a socket housing 11, one end of the socket housing 11 is provided with a collimator mounting hole 111, and the other end is provided with a front-end docking hole 112, The collimator mounting hole 111 and the front-end docking hole 112 are connected and the central axes coincide. The end of the front-end docking hole 112 close to the collimator mounting hole 111 is provided with an optical window 12, and the inner wall of the front-end docking hole 112 is provided with a gold-plated layer. The circumferential surface 122 of the window 12 is provided with a gold-plated layer, which is more conducive to welding, and the front-end butt joint hole 112 and the optical window 12 are fixedly connected by welding to meet the airtightness r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com