Hot-line work temperature indicating wax sheet pasting device capable of being continuously operated and operation method

A temperature-indicating wax sheet and live operation technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve problems such as low operation efficiency, and achieve the effect of high operation efficiency and consistent operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

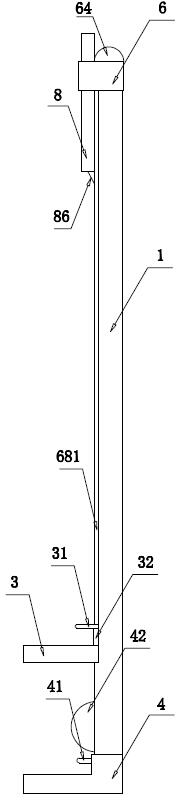

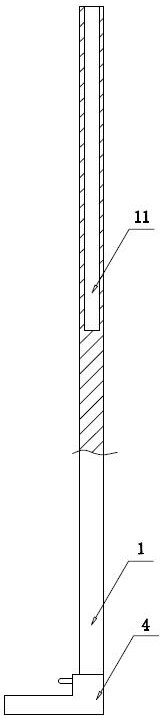

[0034] Such as Figure 1 to Figure 9 As shown, the applicator of the present invention mainly includes an insulating rod 1, a wax sheet storage rod 2, a transfer head 6, an acquisition mechanism and a pasting mechanism. The present invention will be described in detail below with reference to the accompanying drawings.

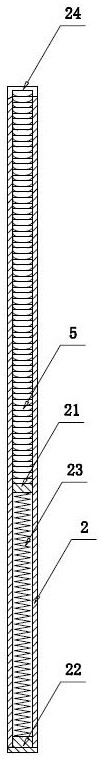

[0035] Such as figure 1 , figure 2 As shown, the insulating rod 1 is a straight rod made of insulating material, which may be an insulating rod of the prior art. A rod groove 11 is provided at the first end of the insulating rod, and the rod groove runs through the end face of the first end of the insulating rod. Wax sheet storage rod 2 is placed in the rod groove, such as image 3 As shown, the wax flake storage rod 2 is an insulating straight rod, the wax flake storage rod is a hollow structure, the first end of the wax flake storage rod is open, and the end face of the second end of the wax flake storage rod is provided with a gap 24. The first end scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com