On-site dismantling and assembling method of large oil tank of fast gate for water inlet accident of high water head power station

A disassembly method and water inlet technology, applied in hydroelectric power stations, hydroelectric power generation, water conservancy projects, etc., can solve problems such as heavy workload, long construction period, hydraulic hoist cylinders that do not have the conditions for on-site disassembly and maintenance, and achieve The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

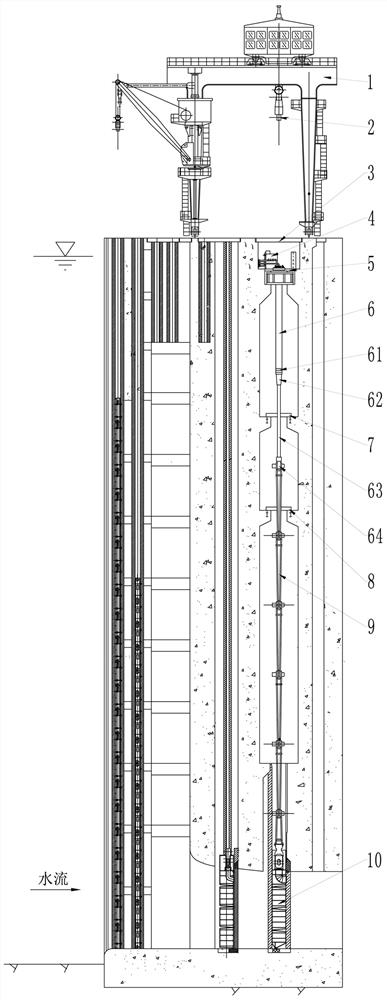

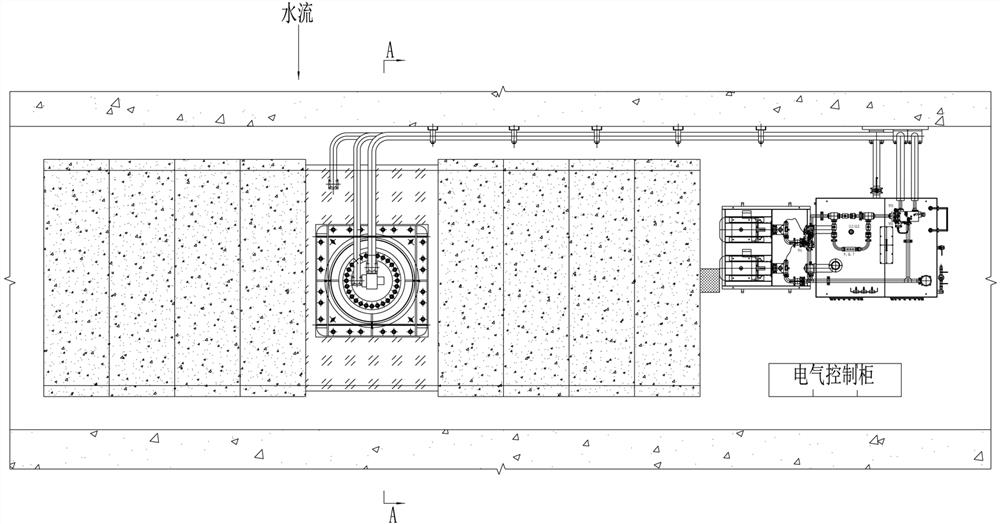

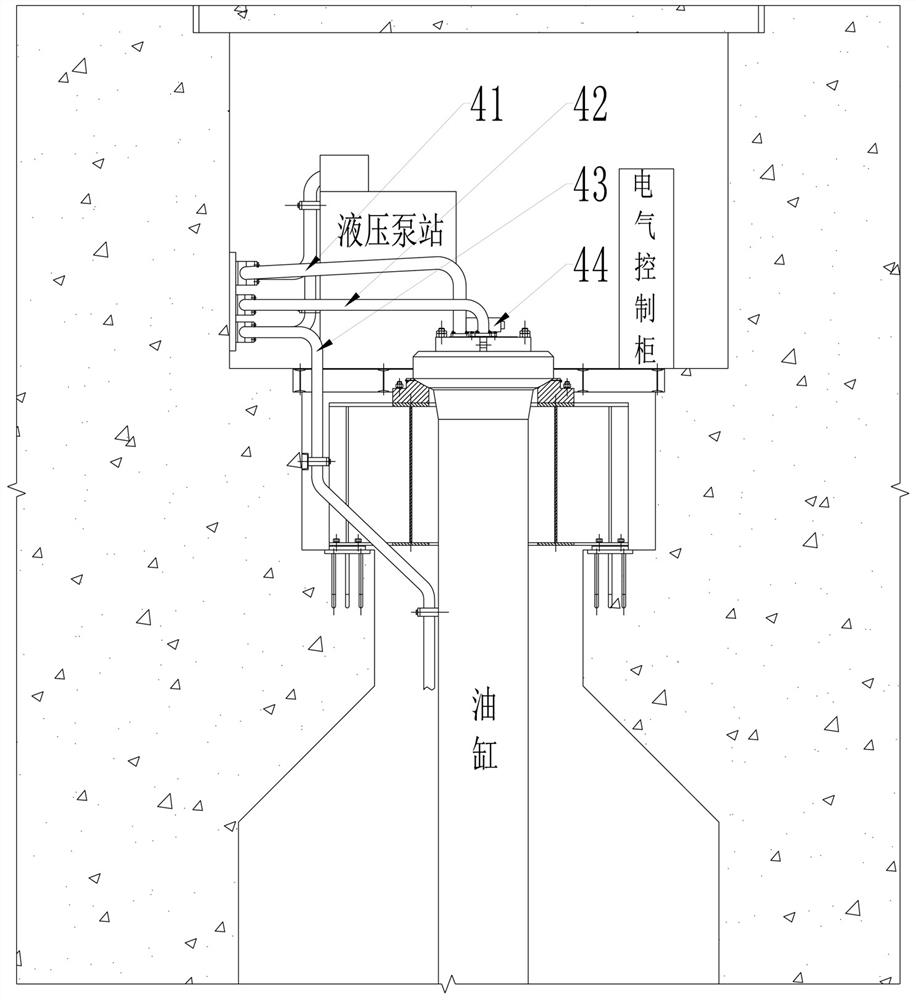

[0046] Such as Figure 1 ~ 9 Among the high-water head power stations, the fast gate of the inlet accident, the lack of large cylinders, including the following steps:

[0047]Step 1, install protection, set a safety isolation fence in the opening and clutch pump room hole and accident, fast gate orifice, in the door slot, facing the installation guardrail and anti-fall equipment; its purpose is to implement the maintenance Effective protection of the area within the region.

[0048] Preferably, in step 1, a specialized protective isolation fence is set in the EL.610 platform opening and closing machine pump room hole and EL.606 pump house.

[0049] Step 2, the platform is set, and the full-hand repair platform 7 is set on the maintenance platform 7 of the cylinder 6 clock portion; its purpose is to ensure that the maintenance area is safe.

[0050] Preferably, it is a working platform for maintenance personnel working on the EL.577 cantilete platform 8 in the gate opening, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com