Conveying belt reversing device

A technology of reversing device and conveyor belt, applied in the direction of conveyor control device, conveyor, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

[0039] The embodiment of the present application discloses a conveyor belt reversing device.

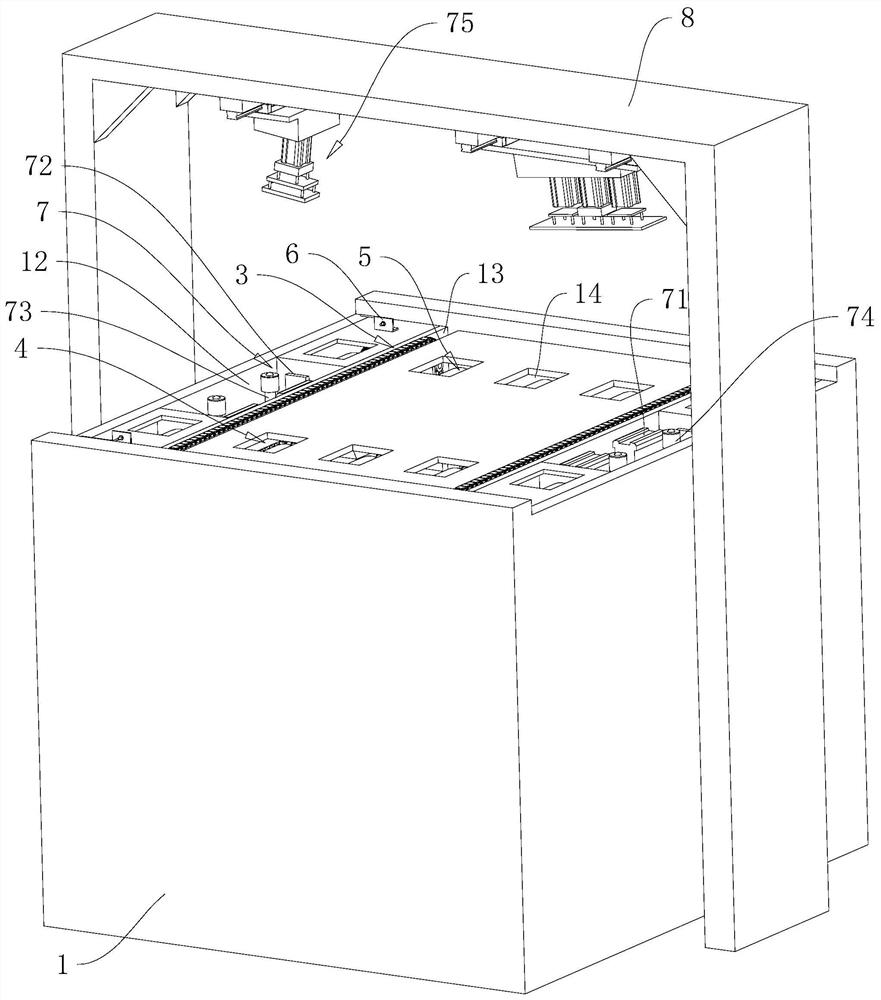

[0040] refer to figure 1 , a conveyor belt reversing device, including a workbench 1 and a lifting assembly 2 installed on the workbench 1, a horizontal conveying assembly 3, a sending assembly 4, a sending assembly 5, a position signal detection assembly and a jacking assembly 7, wherein The conveying direction of the sending-in assembly 4 and the sending-out assembly 5 is set along the width direction of the workbench 1 , and the conveying direction of the transverse conveyance assembly 3 is set along the length direction of the workbench 1 .

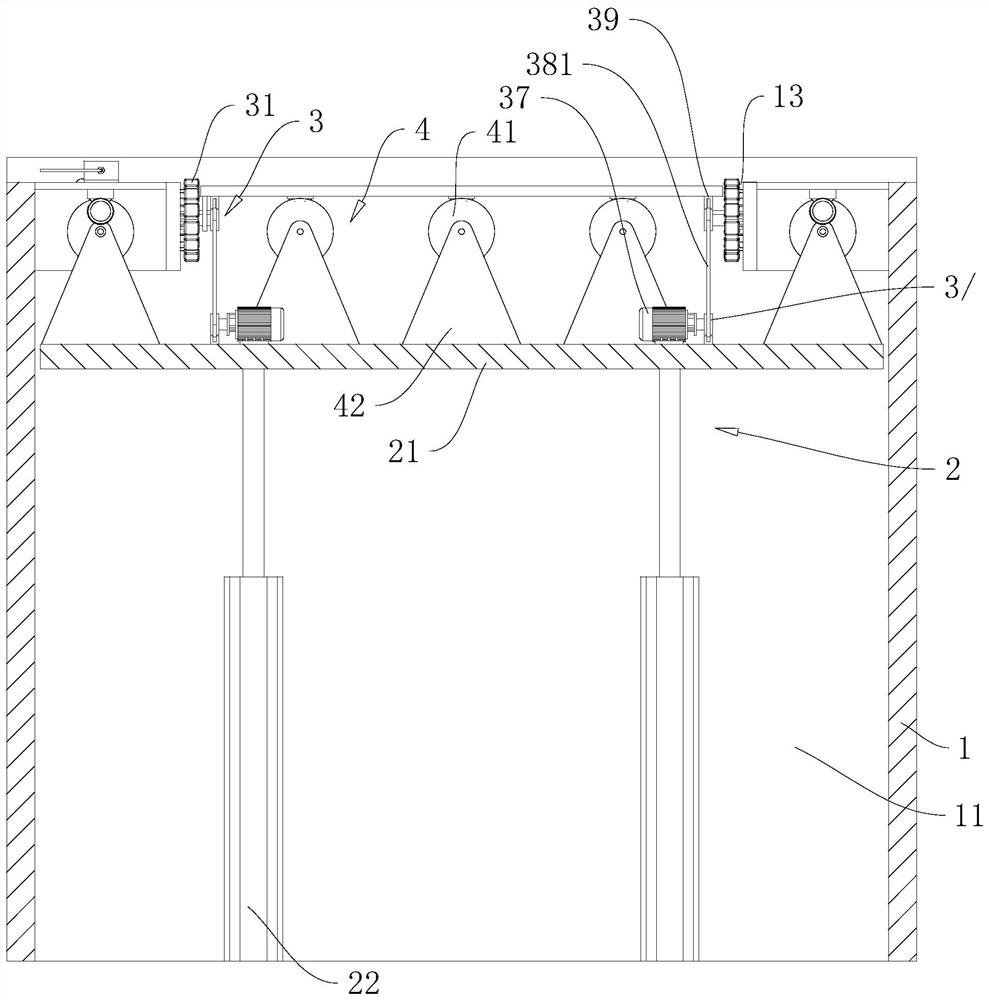

[0041] refer to figure 2 , the workbench 1 is an internal hollow shell, and its internal cavity is set as a working chamber 11. The lifting assembly 2 includes a lifting platform 21 and a lifting cylinder 22. The lifting platform 21 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com