Cast steel riser clamping and transferring device

A transfer device and riser technology, applied in the direction of transportation and packaging, single-axis trolley, trolley accessories, etc., can solve the problems of low transfer efficiency, high transfer cost, time-consuming and labor-intensive collection, etc., to achieve improved production efficiency, low labor intensity, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objects, features and advantages of the present invention more obvious and understandable, the technical solutions in the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the present invention is not limited by the following examples, and specific implementations can be determined according to the technical solutions and actual conditions of the present invention.

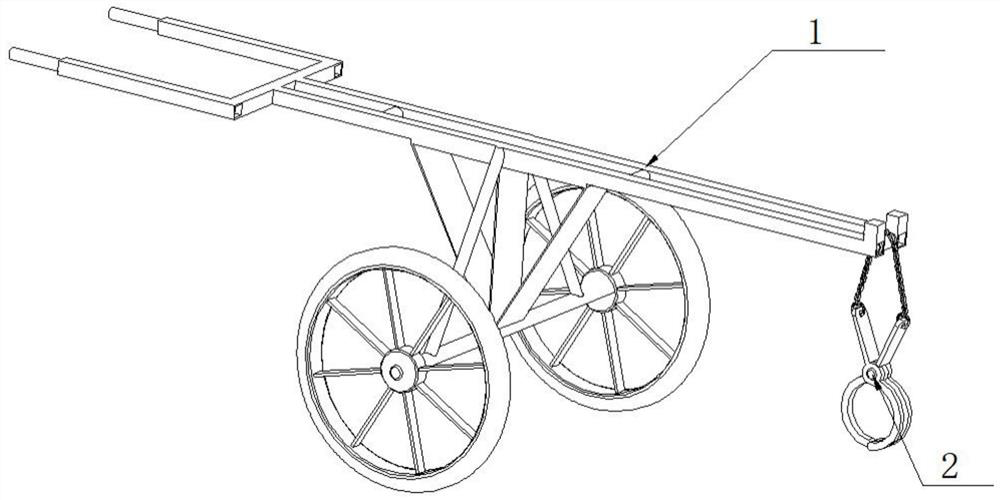

[0017] see figure 1 , a cast steel riser clamping and transferring device includes a lever-type two-wheel mobile trolley 1 and a clamping device 2 .

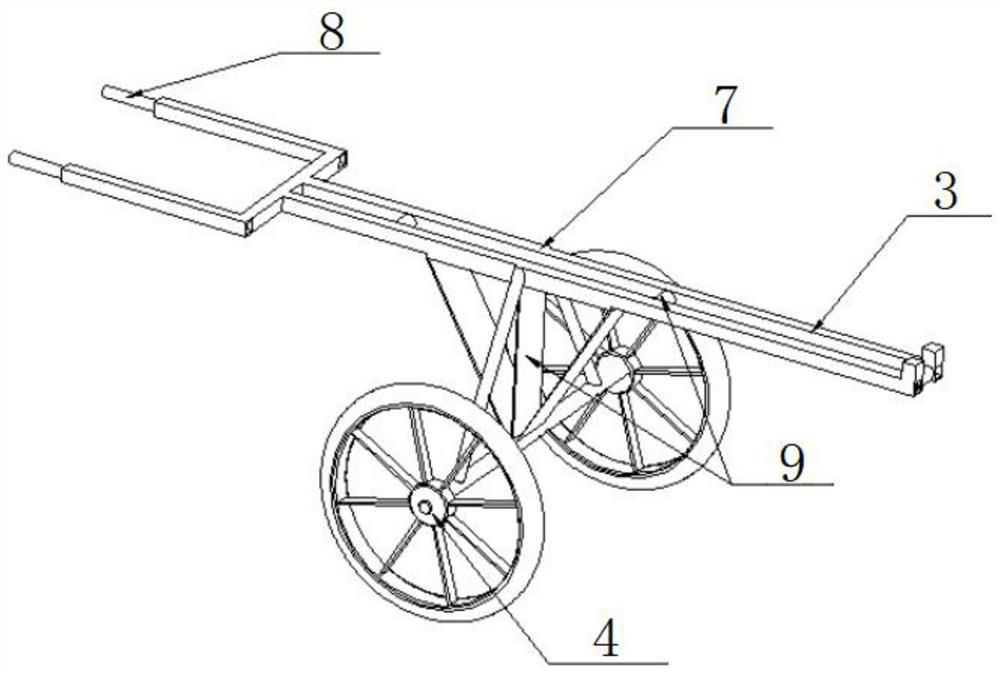

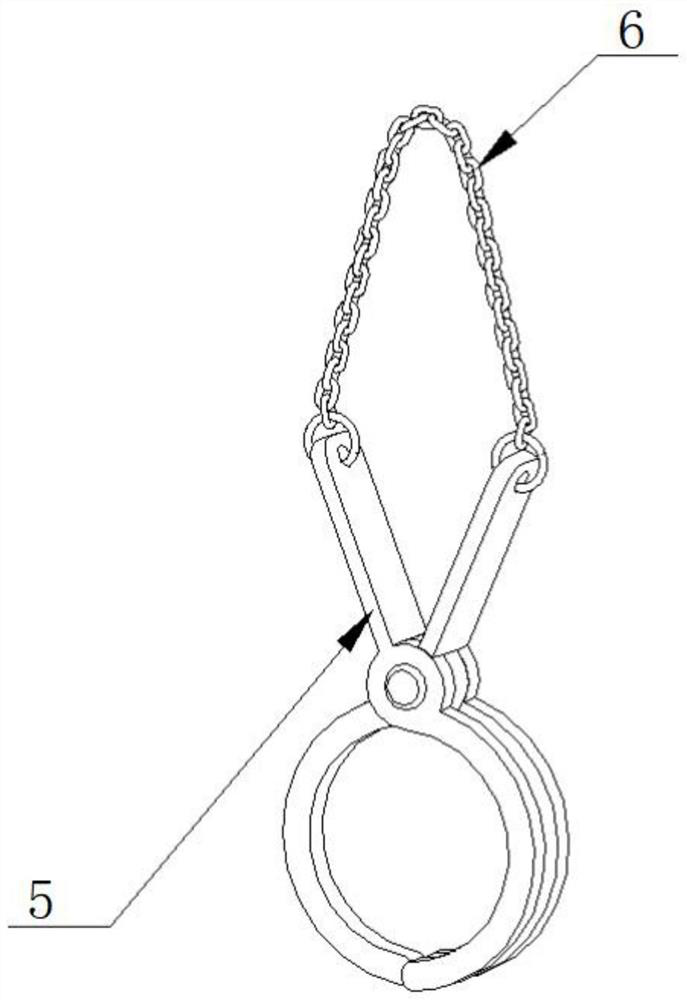

[0018] see figure 2 , the lever-type two-wheel mobile trolley 1 includes a frame 3 and a traveling device 4, the frame 3 is welded by steel, the frame 3 is installed on the traveling device 4, the frame 3 includes a body 7, and the body One end of the 7 is provided with a handle 8 for applying force, and the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com