Shape memory alloy soft body driver

A software driver and memory alloy technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of heat dissipation without considering shape memory alloys, long cooling time of materials, and limited response speed of software drivers, so as to accelerate heat dissipation. , The effect of simple manufacturing process and large load-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

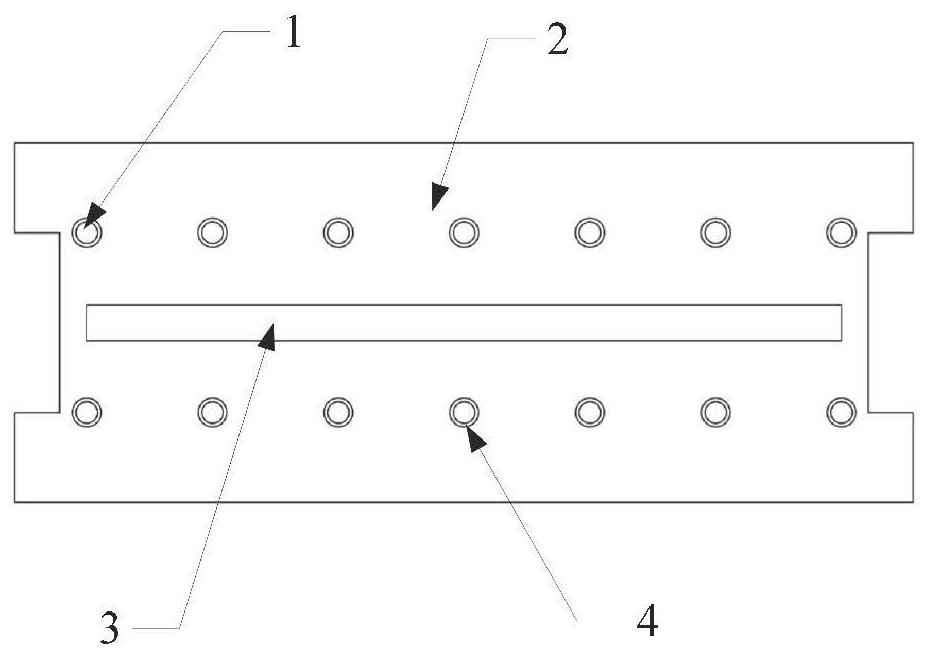

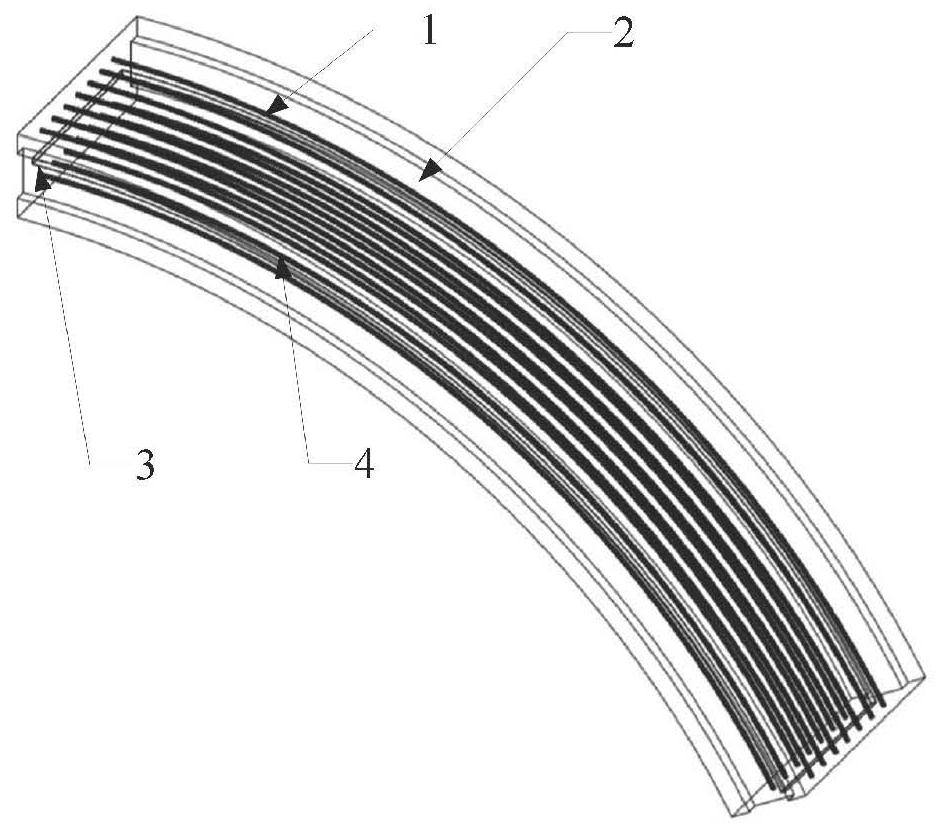

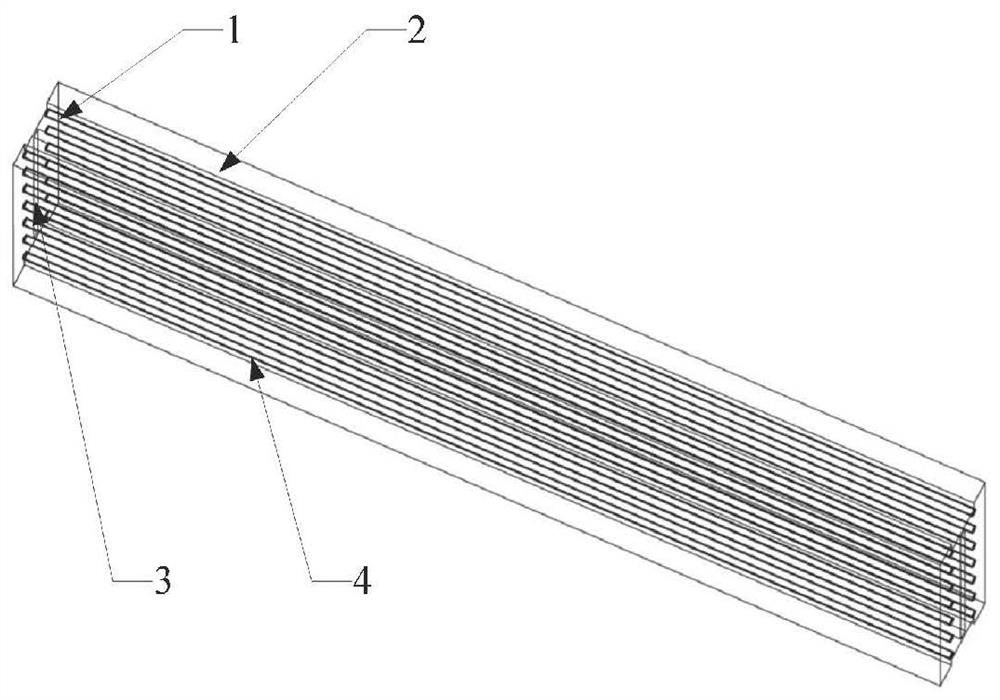

[0031] see figure 1 , a shape-memory alloy software driver, comprising a shape-memory alloy wire 1, a flexible substrate 2, a reinforcement layer 3 and a heat dissipation coating 4, the shape-memory alloy wire 1 is arranged in the flexible substrate 2, and the reinforcement layer 3 is arranged in On the neutral surface of the flexible substrate 2 , the heat dissipation coating 4 is sprayed on the surface of the shape memory alloy wire 1 .

[0032] The shape memory alloy soft driver of this embodiment can be applied to the field of software robot technology. The driver has the advantages of fast response, convenient manufacture, and integration of the traditional structure of the driver.

Embodiment 2

[0034] In the above embodiments, the material of the shape memory alloy wire 1 has a high phase transition temperature characteristic.

[0035] The material of the flexible base 2 is thermal conductive rubber.

[0036] The material of the reinforcing layer 3 is glass fiber.

[0037] The material of the heat dissipation coating 4 is graphene.

[0038] The diameter of the shape memory alloy wires 1 is small and a plurality of them are symmetrically distributed on both sides of the reinforcement layer 3 , and the longitudinal directions of the reinforcement layer 3 and the shape memory alloy wires 1 are parallel.

[0039] The cross-sectional shape of the flexible base 2 is I-shaped.

[0040] In this embodiment, heat-conducting rubber is used as the substrate material, graphene is used as the coating material of the shape memory alloy wire, and the cross section of the flexible substrate is set as an I-shape; through the above measures, the design of the shape memory alloy softw...

Embodiment 3

[0042] A shape memory alloy soft drive, such as figure 1 As shown, it includes a shape memory alloy wire 1, a flexible substrate 2, a reinforcement layer 3, and a heat dissipation coating 4. The shape memory alloy wire 1 is arranged in the flexible substrate 2, and the reinforcement layer 3 is arranged in the center of the flexible substrate 2, so The heat dissipation coating 4 is sprayed on the surface of the shape memory alloy wire 1 .

[0043] The material of the shape memory alloy wire 1 has a relatively high phase transition temperature. Specifically, the material of the shape memory alloy wire 1 may be a nickel-titanium material with a high phase transition temperature, or any other suitable material.

[0044] The flexible base 2 is made of materials with good elasticity and thermal conductivity. The material of the flexible base 2 is thermal conductive rubber. The material of the reinforcing layer 3 is glass fiber. The flexible substrate 2 and the reinforcing layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com