Closed environment-friendly pipe polishing machine with multiple filtering and dust removing functions

A multi-filtration, closed technology, used in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as dust scattering, human injury, production workshop pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

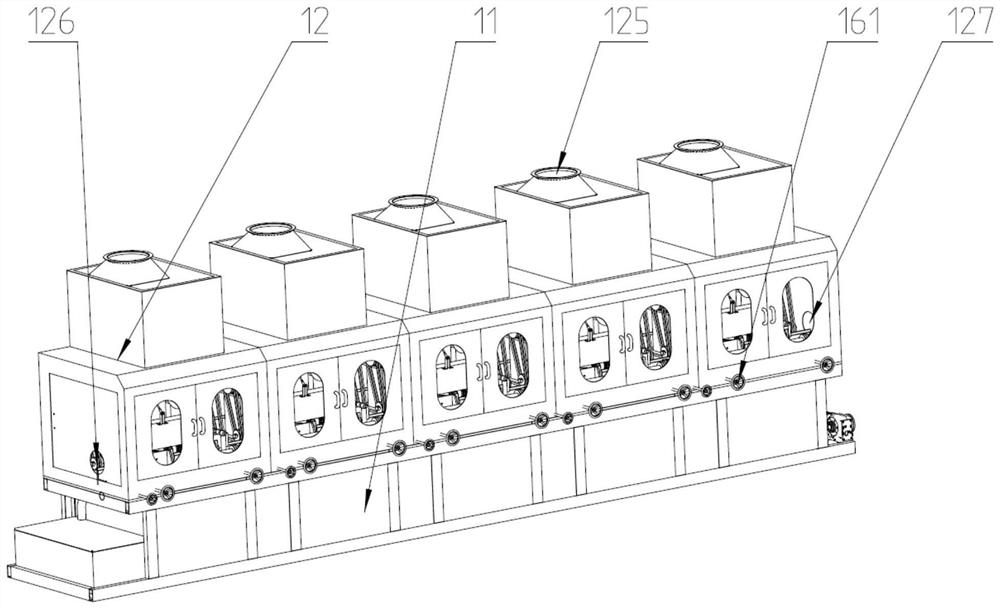

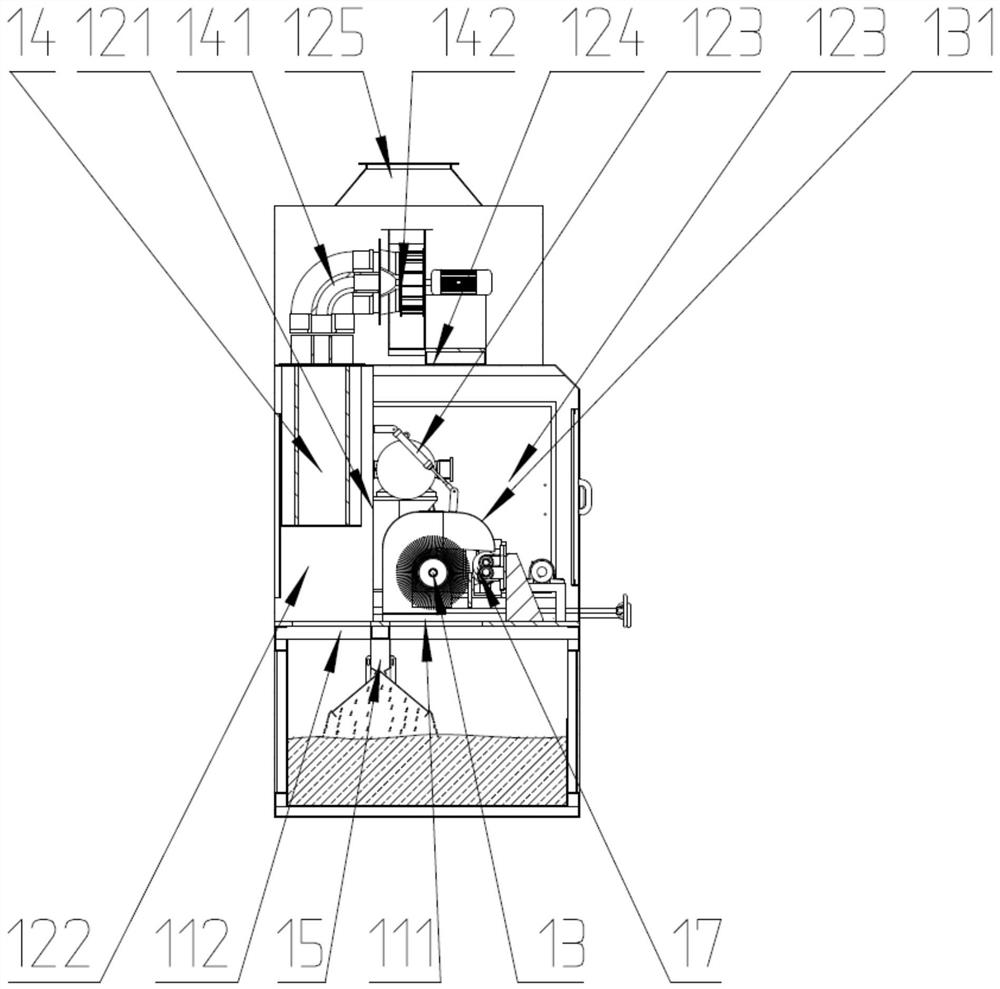

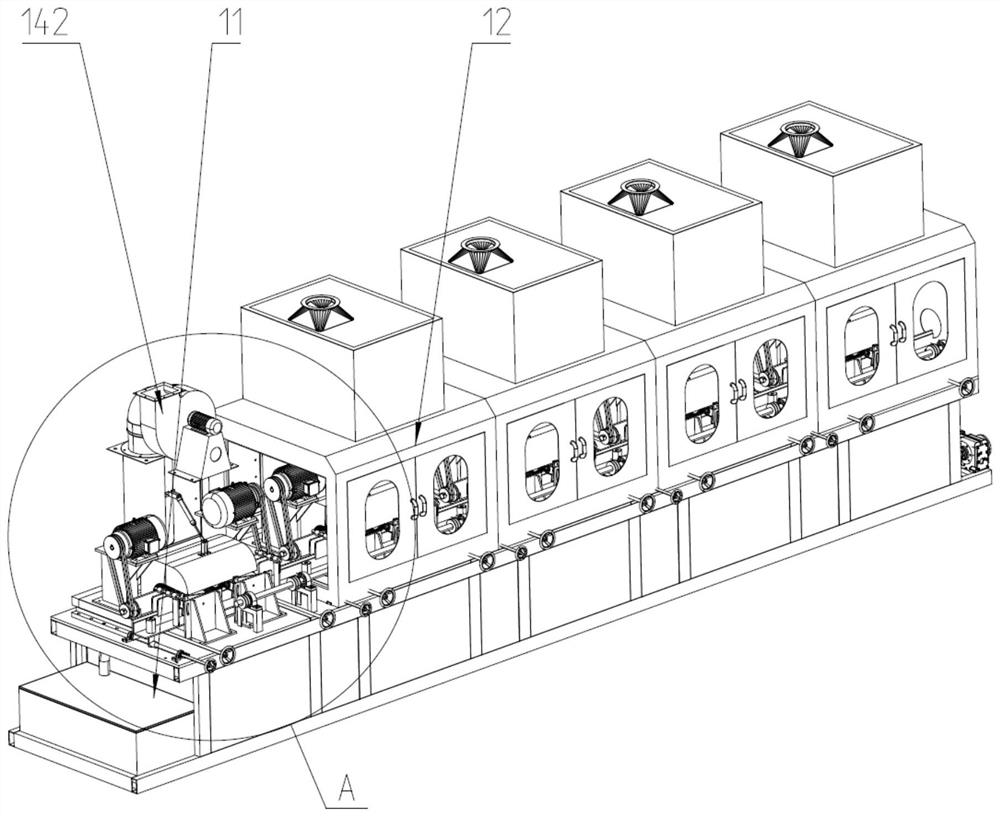

[0026] see Figure 1-6 , a closed-type environmental protection pipe polishing machine with multiple filters and dust removal, including a water tank 11, the water tank 11 is arranged below, and part of the water is poured into the water tank 11 to form an adsorption layer, which can filter the dust-entrained air entering the water tank 11 ; The top of the water tank 11 is provided with a casing 12, which seals the entire polishing machine and plays a role in preliminary noise reduction; above the water tank 11 and is located in the casing 12, a first partition 121 is installed. Preferably, the The first partition 121 can be a steel plate of the water tank 11 itself, or an additional steel plate.

[0027] The first dividing plate 121 divides the inside of the housing 12 into a dust removal channel 122 and a polishing area 123; on the water tank 11 and on both sides of the first dividing plate 121, a dust inlet 111 and a dust outlet 112 are provided, that is, the dust will flow...

Embodiment 2

[0033] Embodiment 2 is a further description of Embodiment 1, and the same parts will not be repeated here, please refer to Figure 1-6, the polishing cover 131 can be opened and closed; preferably, the polishing cover 131 is connected to one end of the opening and closing cylinder 132, and the other end of the opening and closing cylinder 132 is connected to the first partition 121, in order to ensure The normal flipping of the polishing cover 131, the front part of the polishing cover 131 is connected with the rear part by a hinge, the front part of the polishing cover 131 is connected with the opening and closing cylinder 132, and the opening and closing of the polishing cover 131 is realized by the expansion and contraction of the opening and the cylinder. Closed to facilitate the cleaning of the opening and closing cover plate, preferably, in order to further facilitate cleaning, an operation door and an observation window can also be set on the side of the housing 12.

Embodiment 3

[0035] The third embodiment is a further description of the first embodiment, and the same parts will not be repeated here, please refer to Figure 1-6 In the water tank 11 and below the first partition 121, an adjustable water curtain device 15 is provided; the adjustable water curtain device 15 includes a water storage pipe 151, and the water storage pipe 151 communicates with the water tank 11 through a water pump to realize water circulation, preferably Specifically, the other end of the water storage pipe 151 is open or provided with a water outlet 152 etc., so that the water can flow into the water tank 11 again.

[0036] A water outlet 152 is provided below the water storage pipe 151, and an adjustable water curtain plate is installed on the water outlet 152; the water curtain plate is divided into a first water curtain plate 153 and a second water curtain plate 154. One side of the water curtain plate 153 and the second water curtain plate 154 are closely connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com